Check Operation - VAV Units (optional)

NOTE

Blower

NOTE

For maintenance issues associated with variable frequency drives, consult the drive’s manual supplied with the unit. The drives are programmed at the factory and should not need any adjustment during installation and

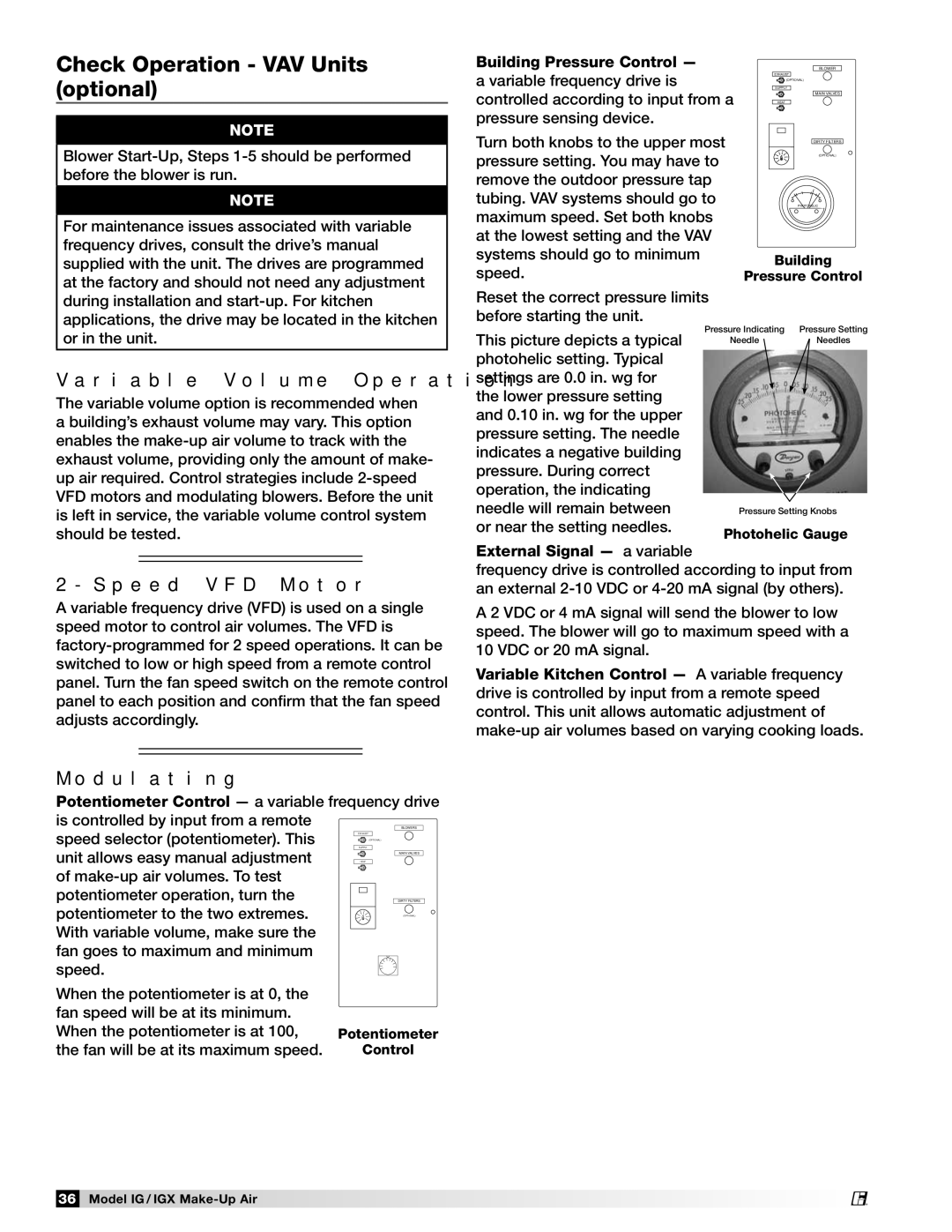

Building Pressure Control —

a variable frequency drive is controlled according to input from a pressure sensing device.

Turn both knobs to the upper most pressure setting. You may have to remove the outdoor pressure tap tubing. VAV systems should go to maximum speed. Set both knobs at the lowest setting and the VAV systems should go to minimum speed.

Reset the correct pressure limits before starting the unit.

BLOWER

EXHAUST

(OPTIONAL)

SUPPLY

|

| MAIN VALVES |

HEAT |

| |

|

| DIRTY FILTERS |

75 | 70 |

|

80 | 65 | (OPTIONAL) |

85 | 60 | |

|

| |

90 | 55 |

|

PHOTOHELIC

Building

Pressure Control

or in the unit.

Variable Volume Operation

The variable volume option is recommended when a building’s exhaust volume may vary. This option enables the

This picture depicts a typical photohelic setting. Typical settings are 0.0 in. wg for the lower pressure setting and 0.10 in. wg for the upper pressure setting. The needle indicates a negative building pressure. During correct operation, the indicating needle will remain between or near the setting needles.

Pressure Indicating | Pressure Setting |

Needle | Needles |

Pressure Setting Knobs

Photohelic Gauge

2-Speed VFD Motor

A variable frequency drive (VFD) is used on a single speed motor to control air volumes. The VFD is

External Signal — a variable

frequency drive is controlled according to input from an external

A 2 VDC or 4 mA signal will send the blower to low speed. The blower will go to maximum speed with a 10 VDC or 20 mA signal.

Variable Kitchen Control — A variable frequency drive is controlled by input from a remote speed control. This unit allows automatic adjustment of

Modulating

Potentiometer Control — a variable frequency drive is controlled by input from a remote

speed selector (potentiometer). This

unit allows easy manual adjustment of

potentiometer operation, turn the

potentiometer to the two extremes. With variable volume, make sure the

fan goes to maximum and minimum speed.

When the potentiometer is at 0, the fan speed will be at its minimum. When the potentiometer is at 100, the fan will be at its maximum speed.

36 Model IG / IGX

®