Maintenance - Routine

Caution

V-Belt Drives

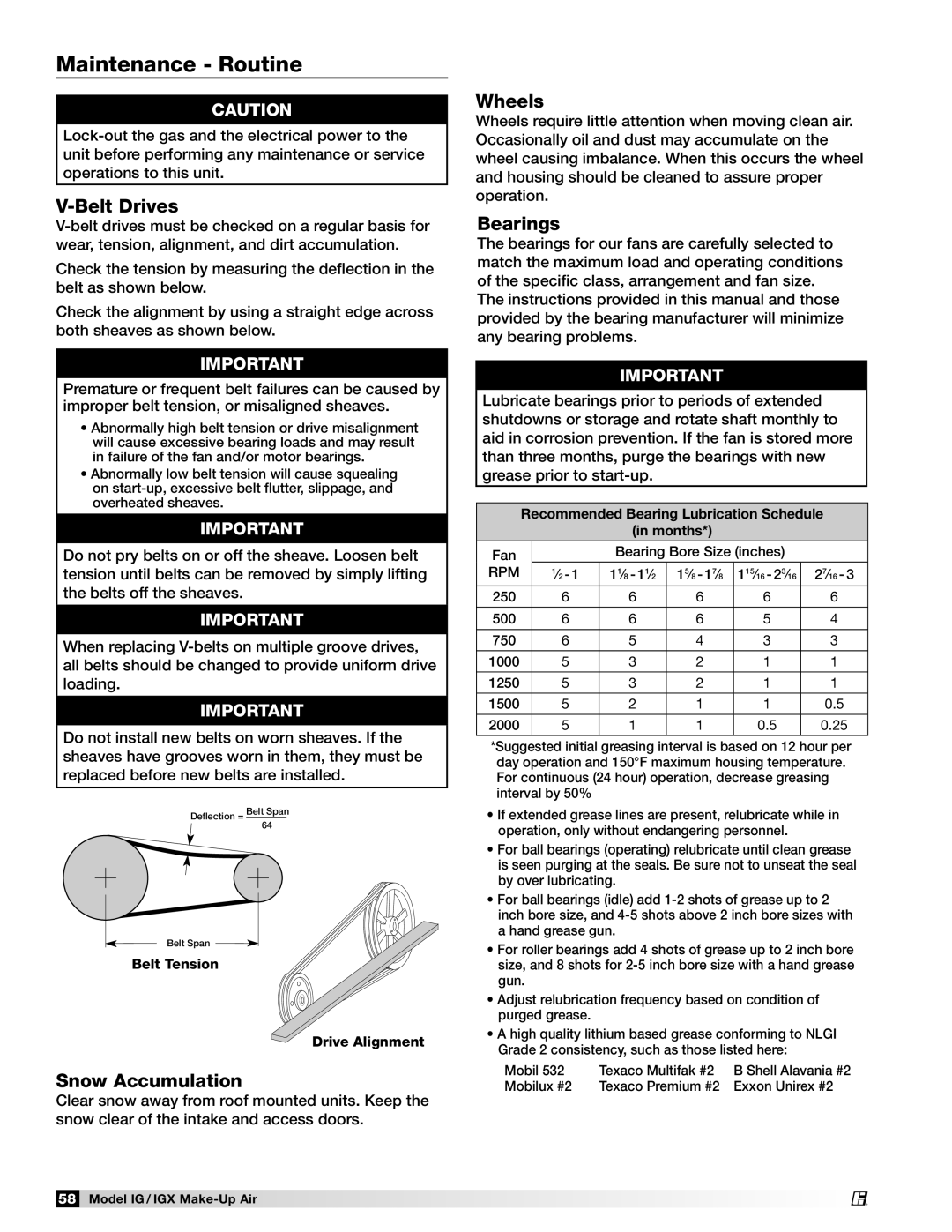

Check the tension by measuring the deflection in the belt as shown below.

Check the alignment by using a straight edge across both sheaves as shown below.

important

Premature or frequent belt failures can be caused by improper belt tension, or misaligned sheaves.

•Abnormally high belt tension or drive misalignment will cause excessive bearing loads and may result in failure of the fan and/or motor bearings.

•Abnormally low belt tension will cause squealing on

important

Do not pry belts on or off the sheave. Loosen belt tension until belts can be removed by simply lifting the belts off the sheaves.

important

When replacing

important

Do not install new belts on worn sheaves. If the sheaves have grooves worn in them, they must be replaced before new belts are installed.

Deflection = Belt Span 64

Belt Span

Belt Tension

Drive Alignment

Snow Accumulation

Clear snow away from roof mounted units. Keep the snow clear of the intake and access doors.

58Model IG / IGX

Wheels

Wheels require little attention when moving clean air. Occasionally oil and dust may accumulate on the wheel causing imbalance. When this occurs the wheel and housing should be cleaned to assure proper operation.

Bearings

The bearings for our fans are carefully selected to match the maximum load and operating conditions of the specific class, arrangement and fan size. The instructions provided in this manual and those provided by the bearing manufacturer will minimize any bearing problems.

IMPORTANT

Lubricate bearings prior to periods of extended shutdowns or storage and rotate shaft monthly to aid in corrosion prevention. If the fan is stored more than three months, purge the bearings with new grease prior to

Recommended Bearing Lubrication Schedule

(in months*)

Fan |

| Bearing Bore Size (inches) |

| ||

RPM | |||||

250 | 6 | 6 | 6 | 6 | 6 |

|

|

|

|

|

|

500 | 6 | 6 | 6 | 5 | 4 |

|

|

|

|

|

|

750 | 6 | 5 | 4 | 3 | 3 |

|

|

|

|

|

|

1000 | 5 | 3 | 2 | 1 | 1 |

|

|

|

|

|

|

1250 | 5 | 3 | 2 | 1 | 1 |

|

|

|

|

|

|

1500 | 5 | 2 | 1 | 1 | 0.5 |

|

|

|

|

|

|

2000 | 5 | 1 | 1 | 0.5 | 0.25 |

|

|

|

|

|

|

*Suggested initial greasing interval is based on 12 hour per day operation and 150°F maximum housing temperature. For continuous (24 hour) operation, decrease greasing interval by 50%

•If extended grease lines are present, relubricate while in operation, only without endangering personnel.

•For ball bearings (operating) relubricate until clean grease is seen purging at the seals. Be sure not to unseat the seal by over lubricating.

•For ball bearings (idle) add

•For roller bearings add 4 shots of grease up to 2 inch bore size, and 8 shots for

•Adjust relubrication frequency based on condition of purged grease.

•A high quality lithium based grease conforming to NLGI

Grade 2 consistency, such as those listed here:

Mobil 532 | Texaco Multifak #2 | B Shell Alavania #2 |

Mobilux #2 | Texaco Premium #2 | Exxon Unirex #2 |

®