Installation of Chilled Water Coil Piping (optional)

Important

Guidelines for the installation of the cooling coil have been provided to ensure proper performance of the coils and their longevity. These are general guidelines that may have to be tailored to meet the specific requirements of any one job. As always, a qualified party or individual should perform the installation and maintenance of the coil. Protective equipment such as safety glasses, steel toe boots and gloves are recommended during the installation and maintenance of the coil.

When installing couplings, do not apply undue stress to the connection. Use a backup pipe wrench to avoid breaking the weld between the coil connection and the header.

All

1. Verify Coil Hand Designation

Check the coil hand

designation to ensure that it matches the system.

Coils are generally

plumbed with the supply connection located on

the bottom of the leaving

return connection at the top of the entering

2. Check the Coil for Leaks

Pressurize the coil to 100 psig with dry nitrogen or other suitable gas. The coil should be left pressurized for a minimum of 10 minutes. If the coil holds the pressure, the

If the pressure drops by 5 psig or less,

3. Connect the Supply & Return Lines

Connect the supply and return lines as shown above.

4. Install the Drain Line |

| ||

Connect an unobstructed |

|

| |

drain line to the drain pan. |

|

| |

A trap should be installed |

| 6 in. min. | |

|

| ||

to prevent sewer gas from | Drain | 6 in. min. | |

being drawn into the unit. | Trap | ||

| |||

Important

All traps must be installed below the roof line or be otherwise protected from freezing.

22Model IG / IGX

Installation of Building Pressure Control (optional)

1. Mount Pressure Tap

Using the factory provided bracket, mount the pressure tap to the

outside of the unit. Choose a location out of the prevailing winds and away from supply or exhaust fans to assure accurate readings.

2. Run Pressure Tap Lines

Run a pressure tap line from the pressure tap on the outside of the unit to the low pressure tap on the back of the photohelic gauge. Run a second pressure tap line from the high pressure tap on the back of the photohelic gauge to the space. Fifty feet of tubing is supplied with the unit.

Factory |

|

|

| High |

|

|

| ||

Wiring |

|

|

| Pressure |

|

|

|

| Tap to |

|

|

|

| space |

Low

Pressure

Tap to

outside

Connections for Photohelic Gauge

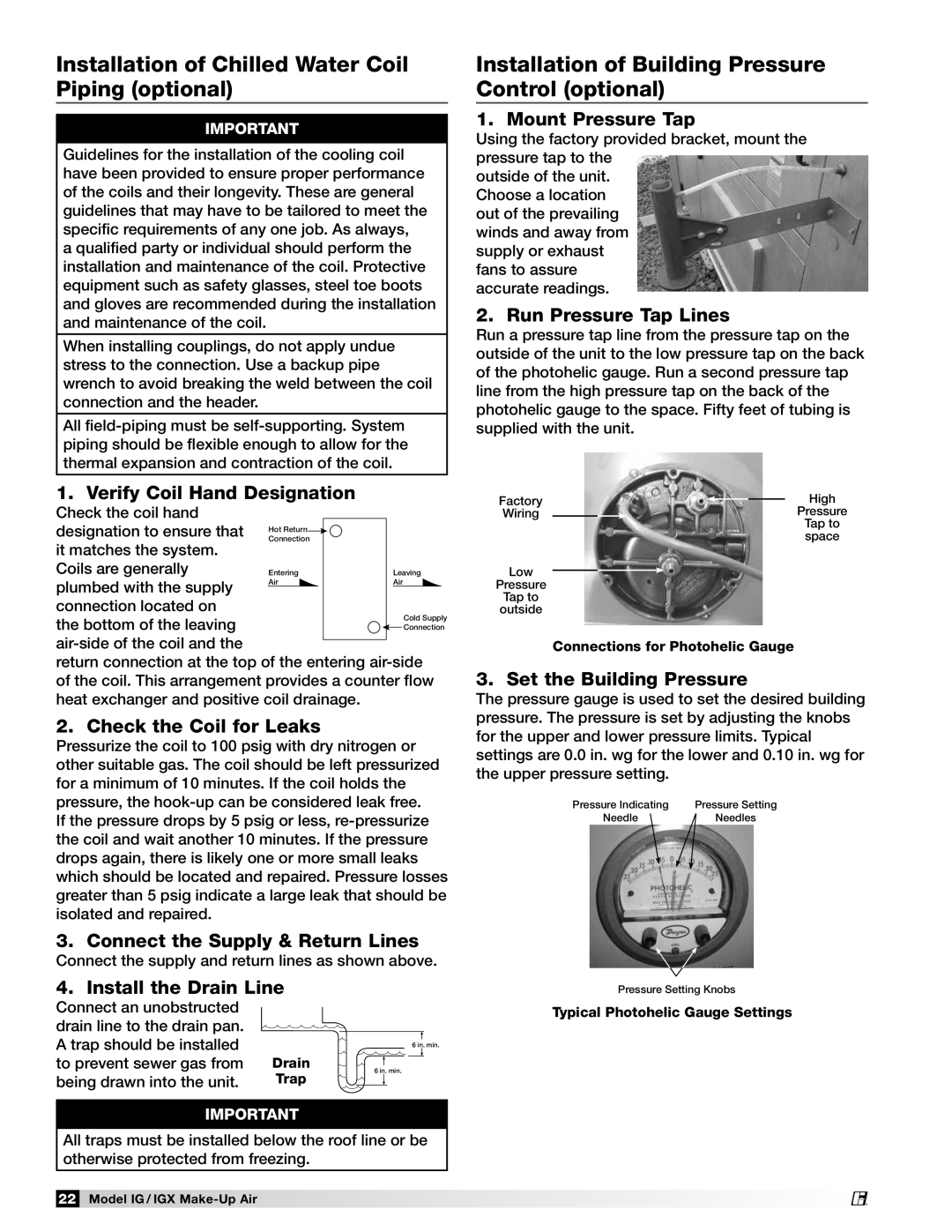

3. Set the Building Pressure

The pressure gauge is used to set the desired building pressure. The pressure is set by adjusting the knobs for the upper and lower pressure limits. Typical settings are 0.0 in. wg for the lower and 0.10 in. wg for the upper pressure setting.

Pressure Indicating | Pressure Setting |

Needle | Needles |

Pressure Setting Knobs

Typical Photohelic Gauge Settings

®