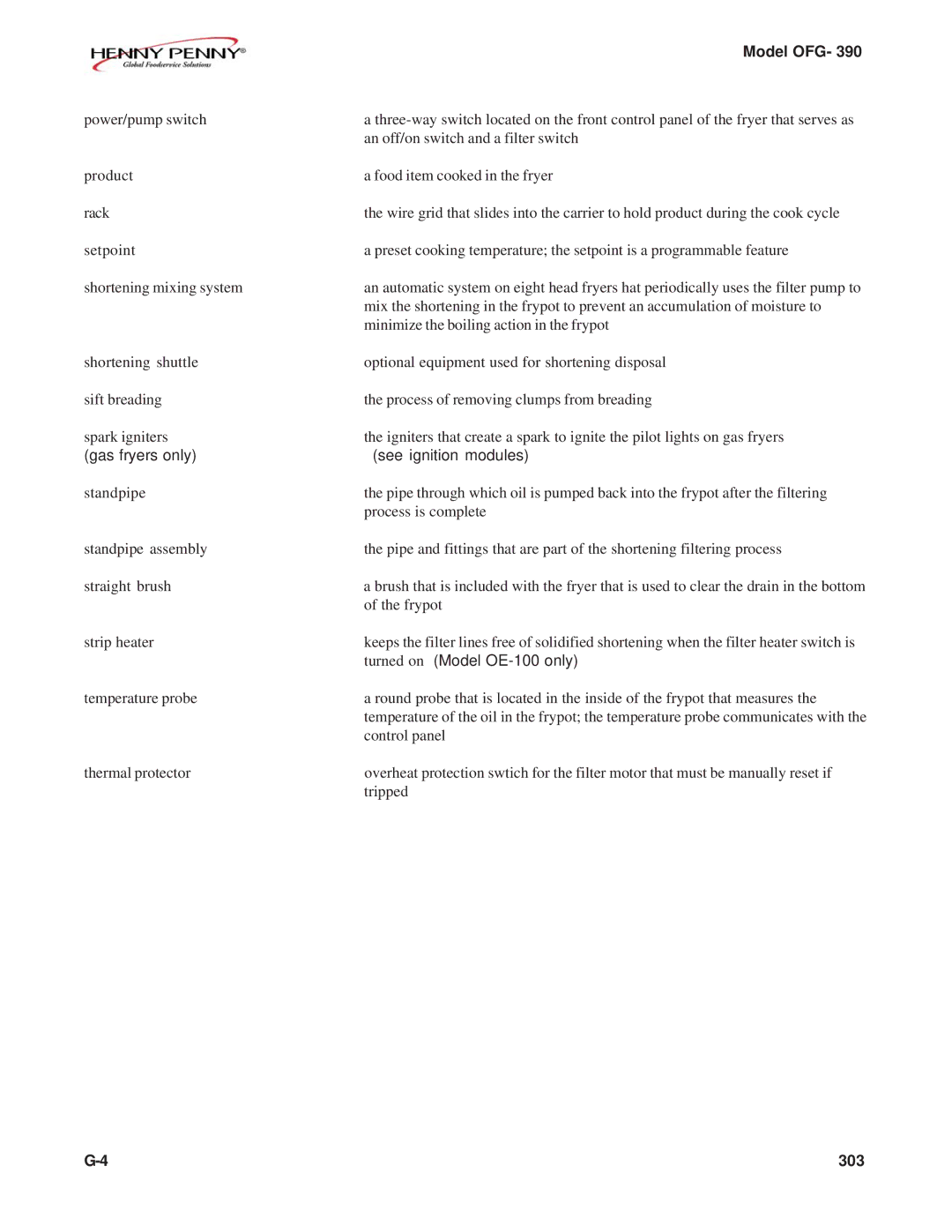

| Model OFG- 390 |

power/pump switch | a |

| an off/on switch and a filter switch |

product | a food item cooked in the fryer |

rack | the wire grid that slides into the carrier to hold product during the cook cycle |

setpoint | a preset cooking temperature; the setpoint is a programmable feature |

shortening mixing system | an automatic system on eight head fryers hat periodically uses the filter pump to |

| mix the shortening in the frypot to prevent an accumulation of moisture to |

| minimize the boiling action in the frypot |

shortening shuttle | optional equipment used for shortening disposal |

sift breading | the process of removing clumps from breading |

spark igniters | the igniters that create a spark to ignite the pilot lights on gas fryers |

(gas fryers only) | (see ignition modules) |

standpipe | the pipe through which oil is pumped back into the frypot after the filtering |

| process is complete |

standpipe assembly | the pipe and fittings that are part of the shortening filtering process |

straight brush | a brush that is included with the fryer that is used to clear the drain in the bottom |

| of the frypot |

strip heater | keeps the filter lines free of solidified shortening when the filter heater switch is |

| turned on (Model |

temperature probe | a round probe that is located in the inside of the frypot that measures the |

| temperature of the oil in the frypot; the temperature probe communicates with the |

| control panel |

thermal protector | overheat protection swtich for the filter motor that must be manually reset if |

| tripped |

303 |