Operating Instructions

Operating instructions

General notes on service

Foreword

Development

Explanation of terminology

Date of issue and manual version November

Foreword

Table of contents

Page

Intended Use

Instructions for the vehicle

Site of operation

Unintended applications

Residual hazards and risks

Instructions for the vehicle

Driver’s licence

Operating instructions

Driver’s licence classes

Over 32 km/h

Operating instructions

Operating instructions

Operating instructions

General notes on safety

Safety

Safety notes for later installations

Work clothing

Gear oil, engine oil, diesel fuel

Safety precautions for handling fuels and oils

Emissions Exhaust gases

Battery acid

Hydraulic oil, brake fluid

Heat

Battery

Vehicle dimensions Dimensional drawing

Technical data

Table of dimensions C

Technical data

Normal track

1040 mm Vehicle Track width e Total width f Dimension Type

Track widths Tires

Weights

Max Type Weight

Engine specifications

Tires Type

Technical data

Traction hydraulics

Front power lift

Assembly Suppl. information Description Steering

Brakes

Trailer hitch

Working hydraulics with Steering

Assembly Suppl. information Description Rear power lift

Loading platform

Electrical system

Assembly Suppl. information Description PTOs

Fuel system

Vehicle overall

Page

Exhaust gas identification

Noise level

Front left view

Description

Views Vehicle14

Rear right view

Description

Vehicle

Operating controls

Driver’s station

Right front controls console

Right rear console controls

Hand throttle

Rear console controls

Pedals

Joystick

Heater until

Steering wheel adjustment

Multifunctional display, legend

10 9 8

Controls in cabin at front bottom

Controls in cabin at front top

Door controls Door opener

Controls in cabin at rear

Identification plates

Location of plates and labels

Mounting instructions for licence plates

Overview of options and variants selection

Assembly Additional information Dimension/Order No./Type

Assembly Supplementary information Dimension/Order No./Type

Accessories

Page

Taking into operation

Daily checks and services prior to taking into operation

Check and clean the cooler and debris screens

Taking into operation

Turn on the battery isolating switch

Check the engine oil level

Do not fill too much oil

Check the tire inflation pressure

Check the trailer hitch option if required

Check the hydraulic oil level

Approx L

Filling fuel

Check the brake fluid level

Adjust the steering wheel

Do not adjust the steering wheel while driv- ing

Do not adjust the seat while driving. Risk of accidents

Adjust the driver’s seat with mechanical suspension

Adjusting the backrest inclination

Adjusting the driver’s seat with pneumatic suspen- sion

Adjusting the lumbar padding

Adjusting the seat horizontally

Adjusting the driver’s weight

Adjusting the horizontal suspension

Check the lights and rear view mirror

Filling washing water

Starting the engine

Start the engine

BildC164

Check the brakes and steering for proper operation

Before starting to drive

Driving safety rules

Operation

Driving with hydrostatic drive and digital electronics

Operation

Driving

Table of driving ranges

Operation

Stop

Selecting on-road travel transport speed

Setting the working speed of programs 3

Operating instructions

Adjusting the fine control knob

Driving with SDS Special Drive System

Release the inching pedal again after passing

Operating the inching pedal

Obstacle Vehicle will resume the previously selected Speed

Changing the direction of travel

Disengaging the differential lock

Engaging the differential lock

Two-stage steering

Steering

Brakes

Applying the service brake

Applying the parking brake

Parking brake is not intended to be used

Releasing the parking brake

An alarm is sounded when driving with Hand brake applied

Driving on slopes

Uphill

Stationary operation

Special operating instructions

Place the vehicle n level ground in both di- rections

Removal of hydraulic oil for stationary operation

215 Nm

Adjusting the track width

Special operating instructions

Operation in winter Oil preheating

Ballast weights

Winter diesel fuel

Engine oil for winter operation

Page

Possible implements

Safety instructions for handling implements

Operating the implements

Additional information on implements

Operating the implements

Front implement

Rear implement or front/rear combinations

Operating instructions

Attaching implements

Adjusting the length of the pintle hook bar

Adjusting the pintle hooks and pintle hook bars

Both threads must be screwed in equally far

Adjusting the upper link

Equipment must not hit the cabin

Connecting hydraulic lines

Removing implements

Installing the cardan shafts

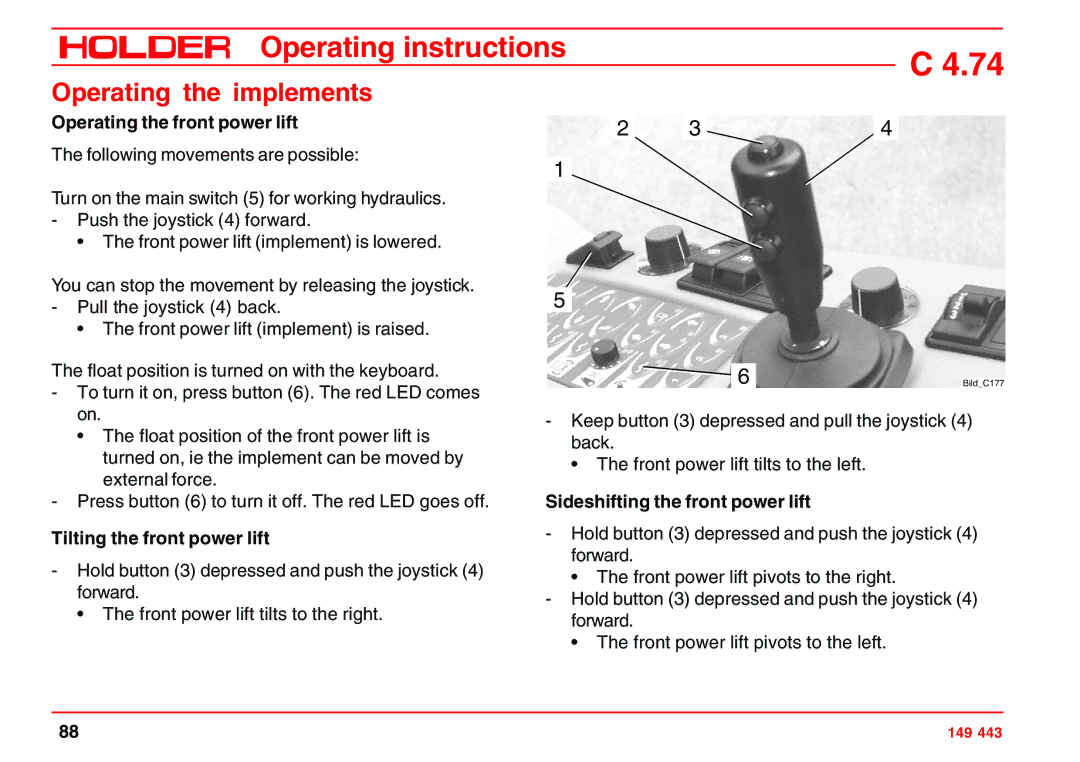

Operating the joystick

Joystick operation

Sideshifting the front power lift

Operating the front power lift

Tilting the front power lift

Operating the front power lift with keyboard

Operating the tilting device with the keyboard

Switching the front power lift to double-acting

Operating the sideshift with the keyboard

Transport safety

External operation of the front power lift

Toggle button for Float Position Button

Flow limiter for joystick

Operating the rear power lift

External operation of the rear power lift

Operating the hydraulic couplings

Operating the yellow and white hydraulic couplings

Operating the green hydraulic couplings

Operating the blue hydraulic couplings

Turning on the front PTO

Turning on the rear PTO

Gas pressure in the diaphragm accumu- lator is 30 bar

Operating the hydraulic cushioning* front power lift

Adjusting the hysteresis

Turning the implement cushioning off

Driving on-road with implement cushioning

Operation with implement cushioning

102

Operating the implements

Turning off the implement variable-displacement Pump

Make sure no-one is standing in the danger zone at the rear

Operating the hydraulic dumper

Slowly increase the speed of the engine

Operating priority flow valve

Press button 4 only at low engine speed

Turning off the priority flow valve

Press button 3 only at low engine speed

109

Page

Operating the driver’s cab

Other activities

Operating the roof hatch Opening the roof hatch

Removing the roof hatch

Front windshield wiper/washer

Other activities

Turning on windshield wiper/washer

Turning on high beam

Turn the preheat/starter switch to position

Lights Turning on and operating the lights

13 14

Operating the horn

Signalling to the left, signalling to the right

Turning on the top headlights

Turning on the rotating beacon

Operating the hazard warning flasher system

Interior light Turning on the interior light

Turning on the flood light

Flood light must not be used in the public traffic area

Radio* and loudspeakers Operating the radio

Power socket Connecting equipment to the power socket

Heating and ventilating Turning on the heater

Heater

Fresh air blower has 2 speeds

Turning on the ventilation

Air conditioning

Cleaning the condenser

Operating the air conditioning

Air conditioning

Vehicle fuses

Fuses

123

Page

Stopping

Taking out of operation

Leaving the vehicle

Shutdown

Taking out of operation

Do not leave the cabin without taking the ig- nition key

Leaving the vehicle

Trailers, towing

Bearing load

Trailers, towing

Operating the trailer hitch manually, attaching trailers

Trailer hitch must be completely closed

Driving with trailers

Instructions for transport

Transport, hoisting, towing

Hoisting instructions

Do not step or stand under a suspended load. Danger

Towing instructions

Transport, hoisting, towing

Brake cable is very taut risk of injury

Secure the vehicle against rolling with chocks

Page

Adjusting the speedometer

Indicators, adjustments

Page

Problems in engine and exhaust gas turbo

Troubleshooting guide

Problems in electronic and hydraulic driving systems

Problem Cause Remedy

Troubleshooting guide

Troubleshooting guide

Cause Remedy

141

Problems in the hydraulic system and steer- ing

143

Problems in the working hydraulic system

145

146

147

Page

Qualification of service personnel

General remarks on maintenance

Service

How to value the vehicle?

Service Hours Date Signature Interval Operation

General remarks on maintenance

Following services were carried out

Handling fuels and lubricants

Safety notes for maintenance

152

Work on the electrical system

Disconnect the battery ground lead

Jacking up

Jack lift points

To lower it, return the changeover lever 1 to the left

Securing the dump body loading platform

Raise the cabin carefully

Tilting the cab

Maintenance after the first 500 hours

Maintenance schedule

Maintenance every 500 hours

Maintenance schedule

Annual maintenance

Maintenance every 1500 hours

Maintenance every 3000 hours

Page

Check the engine for leaks

Maintenance during the first period of operation

Maintenance after the first 50 hours

Page

Adjusting the speedometer

Maintenance as required

Switch layout Tire size Combination

Maintenance as required

Replacement

Cleaning

Page

Clean the cooling system Clean with compressed air

Periodic maintenance Maintenance every 125 hours

Clean with cold cleaner or pressure washer

Check the cooling system

Check the high pressure hoses

Maintenance every 125 hours

Check the battery and cable terminals

Check the brake fluid level for the foot brake

Check the steering cylinder and orbitrol

Do not operate the vehicle with a defective braking system

Check the braking system

Grease the vehicle

215 Nm Check the electrical system

Tighten nuts and bolts

Tighten wheel nuts

Clean the fresh air filter

Page

Change the engine oil

Maintenance every 500 hours

Observe the instructions for handling fuels and lubricants

Litres

Check hose couplings for leaks

Maintenance every 500 hours

Change the engine oil filter

Check the heating system

Page

Check engine valve clearances

Maintenance every 1000 hours

Check the battery

Check V-belt tension and condition

Maintenance every 1000 hours

Service V-belts only with the engine station- ary

Fuel system is bled automatically

Clean / replace the fuel pump strainer

Change the fuel filter and fuel prefilter

Do not inject too much grease to prevent damage to the seal

Lubricating the cardan joint nipples

Change the hydraulic oil while at operating temperature

Maintenance every 1500 hours

Change

Maintenance every 1500 hours

Clean

Matically

Air in the hydraulic system is bled auto

Page

Change the toothed belt

Maintenance every 3000 hours

Check the injection nozzles

Page

Change the brake fluid of the foot brake

Annual maintenance

Page

Engine preservation

Putting the vehicle back in service after lay-up

Laying up

Remove engine preservation

Laying up

Fuel and lubricant recommendations

Recommended engine oils and greases

Fuel and lubricant recommendations

Manufacturer Lubricating oil type

Greases

Fuels

Brake fluid

Do not use mineral oil

Page

Filling quantities

Maintenance data

Tightening torques Hexagon screws and studs

Maintenance data

List of replacement parts Description Order No

Bulbs 12 Lights Rating

Maintenance data

202

100

Alphabetical index

118

Alphabetical index

205

206

207

208

209

210