Envelope construction

Envelope construction is critical. Envelope fold lines can vary considerably, not only between manufacturers, but also within a box from the same manufacturer. Successful printing on envelopes depends upon the quality of the envelopes. When selecting envelopes, consider the following components:

●Weight: The weight of the envelope paper should not exceed 90 g/m2 (24 lb), or jamming might result.

●Construction: Prior to printing, envelopes should lie flat with less than 6 mm (0.25 in.) curl and should not contain air. Envelopes that trap air may cause problems. Do not use envelopes that contain clasps, snaps, tie strings, transparent windows, holes, perforations, cut outs, synthetic materials, stamping, or embossing. Do not use envelopes with adhesives that do not require moistening, but rely instead on pressure to seal them.

●Condition: Make sure that the envelopes are not wrinkled, nicked, or otherwise damaged. Make sure that the envelopes do not have any exposed adhesive.

●Sizes: From 90 x 160 mm (3.5 x 6.3 in.) to 178 x 254 mm (7 x 10 in.).

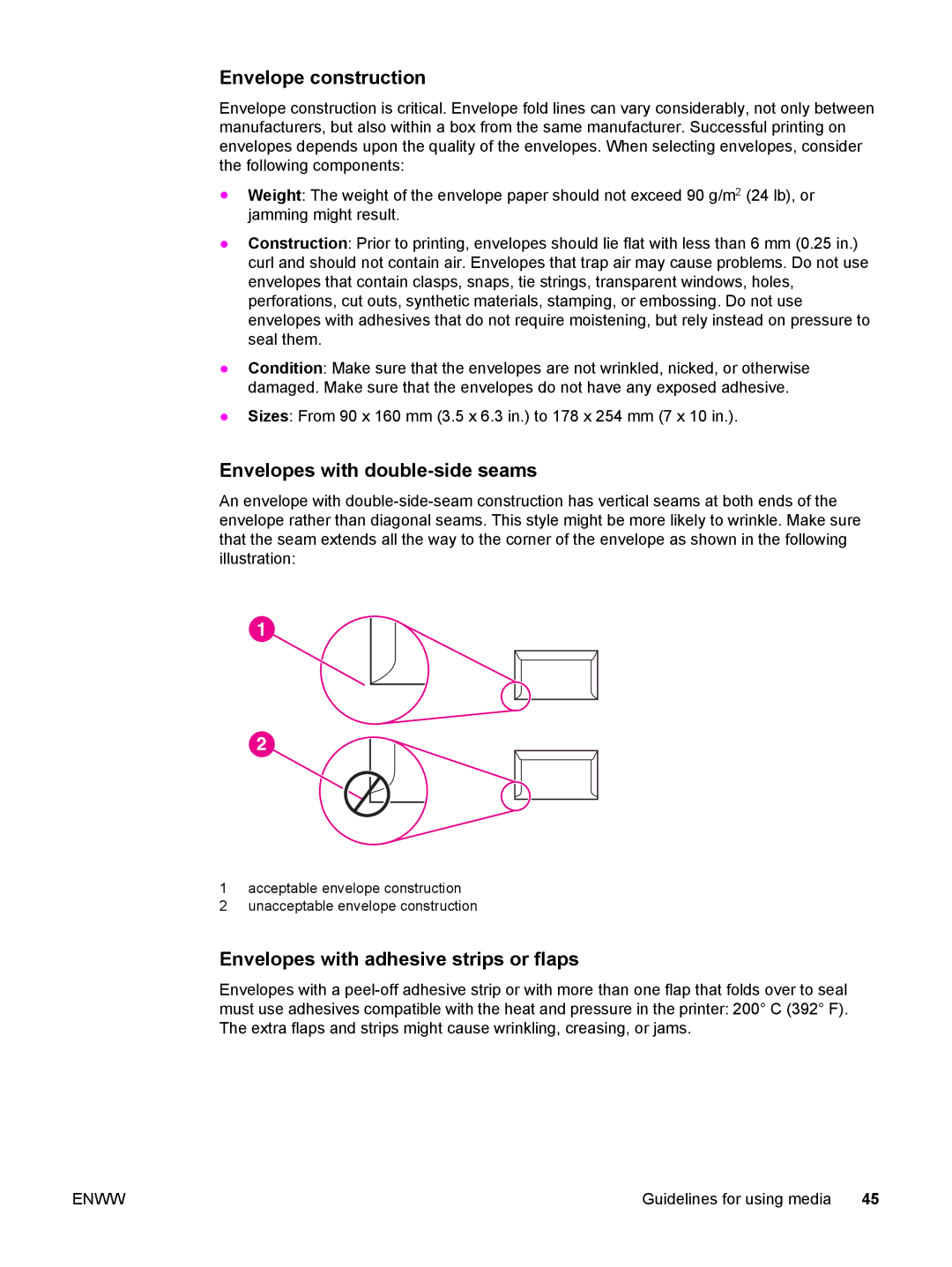

Envelopes with double-side seams

An envelope with

1acceptable envelope construction

2unacceptable envelope construction

Envelopes with adhesive strips or flaps

Envelopes with a

ENWW | Guidelines for using media 45 |