User Manual January Supersedes September

LCX9000 Liquid-Cooled Drives

MN04005001E

Page

Important Notice - Please Read

Table of

CHAPTER 4 - CONTROL WIRING AND INTERNAL CONNECTIONS

Contents

List of Figures

List of Figures Continued

List of Tables

Table 5-11 System Menu Functions

List of Tables Continued

Table 5-13 Resettable Counters

Table A-1 Fault Codes

Definitions and Symbols

Safety

Hazardous High Voltage

Warnings

Warnings, Cautions and Notices

Cautions

Motor and Equipment Safety

Grounding and Ground Fault Protection

Receiving and Inspection

Chapter 1 - Overview

L C X 0 1 6 A 0 - 4 A 2 B

Technical Data

Maintenance

Storage and Shipping

LCX9000 Liquid-Cooled Drives User Manual

Figure 1-1 Liquid-Cooled Drive Principal Block Diagram

Drives

Power Ratings

Page

Page

Table 1-4 Technical Information

Specifications

1-10

Table 1-4 Technical Information Continued

Mounting

Chapter 2 - Installation

Lifting the Drive

Figure 2-2 LCX9000 Liquid-Cooled Drive, CH3

Liquid-Cooled Dimensions

Table 2-1 One-Module Drive Dimensions Mounting Base Included

Drives Consisting of One Module

Top View

Figure 2-3 LCX9000 Liquid-Cooled Drive, CH4

Figure 2-4 LCX9000 Liquid-Cooled Drive, CH5

Bottom View

Figure 2-6 LCX9000 Liquid-Cooled Drive, CH72

Figure 2-5 LCX9000 Liquid-Cooled Drive, CH61

Drives Consisting of Several Modules

Table 2-2 Several Module Drive Dimensions Mounting Bracket Included

Figure 2-7 Drive Mounted Inside Mounting Bracket

Figure 2-8 LCX9000 Liquid-Cooled Drive with Mounting Bracket, CH63

12-Pulse Supply

Figure 2-9 LCX9000 Liquid-Cooled Drive, CH74, IP00

Bottom

6-Pulse Supply

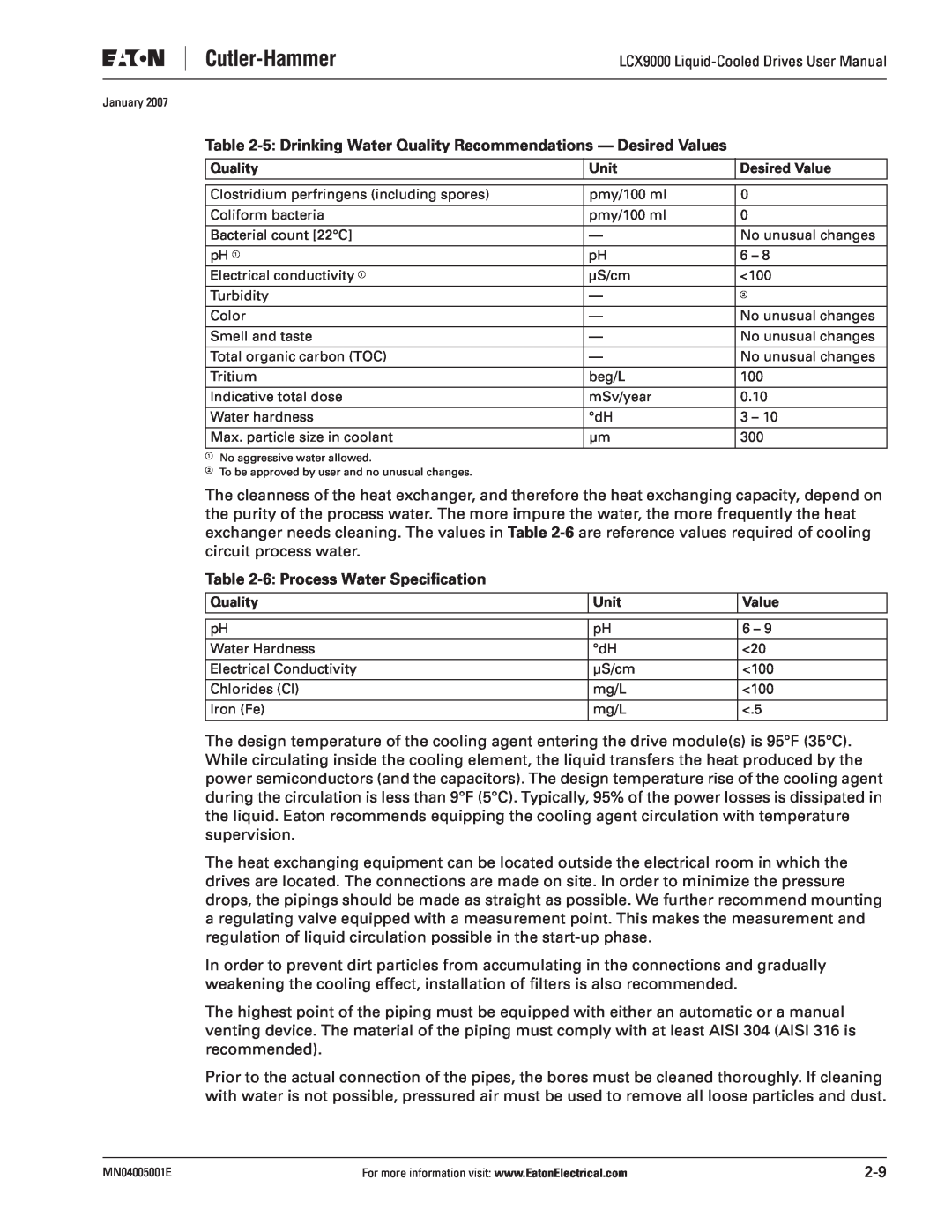

Table 2-4 Drinking Water Quality Recommendations - Maximum Values

Cooling

Drinking Water Specification

Table 2-3 Drinking Water Chemical Specification

Table 2-6 Process Water Specification

Table 2-5 Drinking Water Quality Recommendations - Desired Values

Exchanger

Figure 2-10 Example of Cooling System

Heat

Table 2-7 Information About Cooling Agent and Its Circulation

Figure 2-11 Example PI-Diagram of Cooling System and Connections

Table 2-9 Coolant Volumes and Temperatures

Figure 2-12 Safe Operating Conditions in Relation to Condensation

Condensation

Figure 2-14 External Thread of Hose

Table 2-10 Liquid Connector Types All Pressure Values at Nominal Flow

Cooling System Connections

Figure 2-13 Aluminum Hose Adapters

Figure 2-15 Pressure Loss - CH6x

Pressure Losses Table 2-11 Pressure Losses - CH6x

Outflow Hoses and

rubber EPDM only aluminium other stainless and acid-proof materials

Table 2-12 Pressure Losses - CH7x

Figure 2-16 Pressure Loss - CH7x

The following main line hose materials are acceptable plastic PVC

Fast Connector Lock Screw, Cable Seal and Clamp

Installation of Flow Switch

About Flow Switch Installation

Figure 2-17 Flow Switch Hose Connection, Fast Connector Electrical

External Cooling Fan for CH4

Figure 2-18 Direction of Coolant Circulation

Drive Derating

Input Chokes

Table 2-16 Input Choke Dimensioning, 6-Pulse Supply

Sizes 87 - 145A and 590A

Installation of Input Choke

Figure 2-19 Example of Input Chokes for Liquid-Cooled Sizes Up to 62A

Figure 2-20 Example of Input Chokes for Liquid-Cooled

January

Table 2-17 Choke Dimensions Sizes 23 - 145A and 590A

Table 2-18 Choke Dimensions Sizes 261 - 1150A

LCX9000 Liquid-Cooled Drives User Manual

Motor Cable

Chapter 3 - Power Wiring

Power Connections

Mains Cable

Cable Data

Table 3-1 Cable Types Required to Meet Standards

Table 3-2 Cable Sizes 400

Three grounding terminals per mounting plate, see Page

Table 3-2 Cable Sizes 400 - 500V Continued

Units with 6-pulse supply

Units with 12-pulse supply

Table 3-4 Tightening Torques of Bolts

Table 3-3 Cable Sizes 525

See the tightening torques of bolts in Table

Table 3-5 Fuse Sizes for LCX9000 Liquid-Cooled 500V Drives

Fuse Sizes, Drives

Fuse information

Table 3-6 Fuse Sizes for LCX9000 Liquid-Cooled 690V Drives

The maximum length of the motor cables is 984 feet 300m

Cable Installation Instructions

4. If cable insulation checks are needed, see Page

Figure 3-1 Maximum Terminal Stresses

Figure 3-2 Installation Space

Installation Space

Cable Installation and the UL Standards

Grounding of Power Unit

Figure 3-3 Grounding Terminal on Mounting Plate

Cable and Motor Insulation Checks

3-12

Figure 4-1 Control Board

Chapter 4 - Control Wiring and Internal Connections

Figure 4-3 Drives Connected in Parallel

Figure 4-2 Basic and Option Board Connections of the Control Board

WRONG Terminal J1 Upper

Control Board Power-Up

Figure 4-4 Connection of Control Board Cable from the Power Board

See Figures 4-4 and

Figure 4-6 I/O Terminals of the Two Basic Boards

Figure 4-5 Connection of Control Board Cable from the Power Board

Control Connections

CORRECT Terminal J2 Lower

Figure 4-8 General Wiring Diagram of the Basic Relay Board OPT-A2

Figure 4-7 General Wiring Diagram of the Basic I/O Board OPT-A9

Galvanic Isolation Barriers

Control Cables

Figure 4-9 Galvanic Isolation Barriers

Table 4-1 Control I/O Terminal Signals

Control Terminal Signals

Figure 4-11 Jumper Blocks on OPT-A9

Digital Input Signal Inversions

Figure 4-10 Positive/Negative Logic

Jumper Selections on the OPT-A9 Basic Board

AO1 Mode

Figure 4-12 Jumper Selection for OPT-A9

AI1 Mode

AI2 Mode

Figure 4-13 Control Unit Mounting Box

Installing the Control Unit Mounting Box

Figure 4-14 Control Unit Installed into the Mounting Box

Control Unit Mounting Box

Table 4-2 Installing the Control Unit Mounting Box

January MN04005001E

Table 4-2 Installing the Control Unit Mounting Box Continued

Internal Connections

Connections between Power Unit ASIC and Driver Boards

X29 Flow supervision input

Figure 4-15 Terminals and Connections between ASIC and Driver Board

CH61, CH62 and CH72 Table 4-3 Terminals CH61, CH62 and CH72

X9 OEVA feedback X15 Charging relay output X6 DC terminal

Connect to WL on Phase V/W driver board

Table 4-4 Terminals CH63

Table 4-5 Terminals between Driver Boards CH64 and CH74

Connections with Optical Cable

Connections between Power Unit ASIC and the Control Unit

Figure 4-18 Remove Cover to Access Power Unit

Connections with Round Cable

Control board connection

Figure 4-19 Optical Cable Adapter Board

Table 4-6 Terminals on Adapter Board

Supply voltage 24Vin from power unit

Figure 5-1 Control Keypad and Drive Status Indications

Indicators on the Keypad Display

Chapter 5 - Menu Information

Keypad Operation

Table 5-2 Control Place Indicators

Drive Status Indicators

Table 5-1 Drive Status Indicators

Control Place Indicators

Text Lines

Keypad Pushbuttons

Status LEDs Green - Green - Red

Table 5-3 Status LEDs Green - Green - Red

Table 5-5 Button Descriptions

Figure 5-3 Keypad Display Data

Menu Navigation

Monitor

Figure 5-4 Keypad Navigation Chart

Figure 5-5 Monitoring Menu

Monitoring Menu M1

Parameter Menu M2

Table 5-6 Monitored Signals

Keypad Control Menu M3

Figure 5-6 Parameter Value Change Procedure

Table 5-7 Keypad Control Parameters, M3

Figure 5-7 Selection of Control Place Keypad Reference

Selection of Control Place

Keypad Direction

Figure 5-8 Normal State, No Faults

Active Faults Menu M4

STOP Button Activated

Fault Type Symbol

Fault Types

Figure 5-9 Fault Display Table 5-8 Fault Types

Fault Time Data Record

Table 5-10 Real Time Record

Table 5-9 Fault Time Recorded Data

Fault History Menu M5

Real Time Record

System Menu M6

Figure 5-10 Fault History Menu

Table 5-11 System Menu Functions

5-16

Table 5-11 System Menu Functions Continued

Figure 5-11 Selection of Language Application Selection

Selection of Language

Figure 5-12 Change of Application

Upload parameters to keypad To keypad, S6.3.2

Copy Parameters

Parameter Sets S6.3.1

Figure 5-13 Storing and Loading of Parameter Sets

Figure 5-14 Parameter Copy to Keypad

Automatic Parameter Backup P6.3.4

Download parameters to drive From keypad, S6.3.3

Figure 5-15 Parameter Comparison

Parameter Comparison

P2.1.2= 20.0 Hz

Figure 5-16 Password Setting

Password S6.5.1

Security

Figure 5-18 Activation of Start-Up Wizard

Parameter Lock P6.5.2

Figure 5-17 Parameter Locking

Start-Up Wizard P6.5.3

Figure 5-21 Default Page Function

Keypad Settings

Figure 5-20 Keypad Settings Submenu

Default Page P6.6.1

Contrast Adjustment P6.6.4

Default page in the operating menu P6.6.2

Timeout Time P6.6.3

Figure 5-22 Timeout Time Setting

HMI Acknowledge Timeout P6.7.3

Hardware Settings

Figure 5-23 HMI Acknowledge Timeout

Table 5-12 Counter Pages

Number of retries to receive HMI acknowledgement P6.7.4

System info

Total Counters

Software S6.8.3

Table 5-13 Resettable Counters

Figure 5-24 Counter Reset

Trip Counters

Hardware S6.8.5

Applications S6.8.4

Table 5-15 Applications Information Pages

Figure 5-25 Applications Info Submenu

Expander Board Menu M7

Expander Boards S6.8.6

Figure 5-26 Expander Board Information Menus

Debug Menu S6.8.7

Figure 5-27 Expander Board Information Menu

Further Keypad Functions

Expander Board Parameters

Table 5-17 Expander Board Parameters Board OPTA1

Chapter 6 - Start-Up

Safety Precautions

Sequence of Operation

Page

January

Table A-1 Fault Codes

Appendix A - Fault Codes

Table A-1 Fault Codes Continued

Table A-1 Fault Codes Continued

Load Test with Motor

DC Link Test without Motor

January

Figure B-1 Main Circuit and Control Diagram, CH3

Main Circuit and Control Diagrams

Appendix B - Technical Reference

ATerm

Figure B-2 Main Circuit and Control Diagram, CH4

Figure B-3 Main Circuit and Control Diagram, CH5

Term

H8...H13

Figure B-4 Main Circuit and Control Diagram, CH61

Figure B-5 Main Circuit and Control Diagram, CH61, Control

SPF1

Figure B-7 Main Circuit and Control Diagram, CH63, Module

Figure B-6 Main Circuit and Control Diagram, CH63, Module

VB00491

Figure B-9 Main Circuit and Control Diagram, CH72

Figure B-8 Main Circuit and Control Diagram, CH63, Control

Figure B-11 Main Circuit and Control Diagram, CH74, Phase U

Figure B-10 Main Circuit and Control Diagram, CH72, Control

Figure B-12 Main Circuit and Control Diagram, CH74, Control

Figure B-13 Fan Mounting Pallet - Hot Dip Zinc Coated

Fan Dimensions

Figure B-14 Fan Support

January

B-10

Page

Publication No. MN04005001E/CPG January

Company Information

Eaton Electrical Inc

2007 Eaton Corporation All Rights Reserved Printed in USA