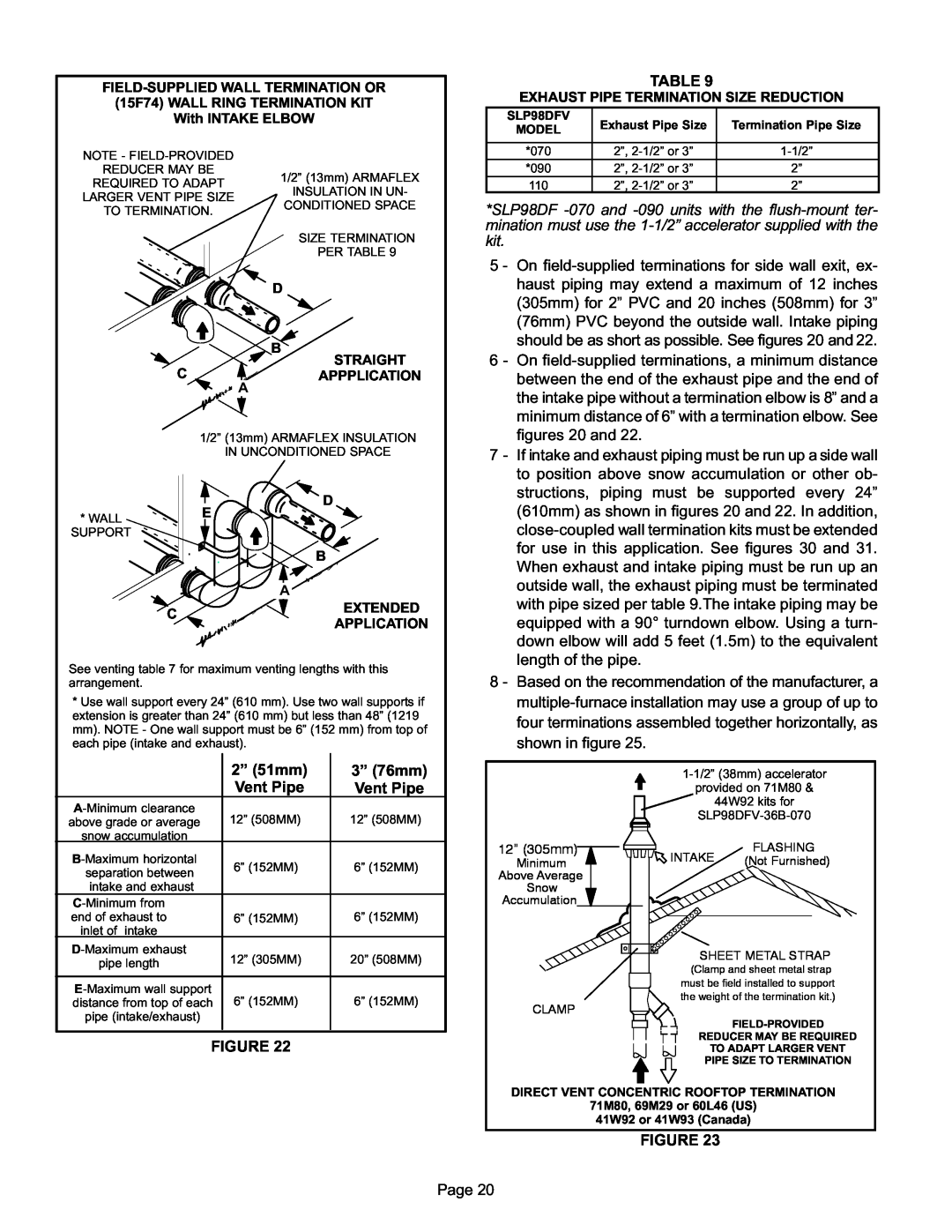

FIELD−SUPPLIED WALL TERMINATION OR (15F74) WALL RING TERMINATION KIT With INTAKE ELBOW

NOTE − FIELD−PROVIDED |

| |

REDUCER MAY BE | 1/2" (13mm) ARMAFLEX | |

REQUIRED TO ADAPT | ||

INSULATION IN UN- | ||

LARGER VENT PIPE SIZE | ||

CONDITIONED SPACE | ||

TO TERMINATION. | ||

| ||

| SIZE TERMINATION | |

| PER TABLE 9 | |

| D | |

| B | |

| STRAIGHT | |

C | APPPLICATION | |

| A |

1/2" (13mm) ARMAFLEX INSULATION

IN UNCONDITIONED SPACE

TABLE 9

EXHAUST PIPE TERMINATION SIZE REDUCTION

SLP98DFV | Exhaust Pipe Size | Termination Pipe Size | |

MODEL | |||

|

| ||

|

|

| |

*070 | 2", 2−1/2" or 3" | 1−1/2" | |

*090 | 2", 2−1/2" or 3" | 2" | |

110 | 2", 2−1/2" or 3" | 2" |

*SLP98DF −070 and −090 units with the flush−mount ter- mination must use the 1−1/2" accelerator supplied with the kit.

5 − On field−supplied terminations for side wall exit, ex- haust piping may extend a maximum of 12 inches (305mm) for 2" PVC and 20 inches (508mm) for 3" (76mm) PVC beyond the outside wall. Intake piping should be as short as possible. See figures 20 and 22.

6 − On field−supplied terminations, a minimum distance between the end of the exhaust pipe and the end of the intake pipe without a termination elbow is 8" and a minimum distance of 6" with a termination elbow. See figures 20 and 22.

7 − If intake and exhaust piping must be run up a side wall |

to position above snow accumulation or other ob- |

* WALL

SUPPORT

C

D

E

B

A

EXTENDED

APPLICATION

structions, piping must be supported every 24" |

(610mm) as shown in figures 20 and 22. In addition, |

close−coupled wall termination kits must be extended |

for use in this application. See figures 30 and 31. |

When exhaust and intake piping must be run up an |

outside wall, the exhaust piping must be terminated |

with pipe sized per table 9.The intake piping may be |

equipped with a 90° turndown elbow. Using a turn- |

down elbow will add 5 feet (1.5m) to the equivalent |

length of the pipe. |

See venting table 7 for maximum venting lengths with this arrangement.

*Use wall support every 24" (610 mm). Use two wall supports if extension is greater than 24" (610 mm) but less than 48" (1219 mm). NOTE − One wall support must be 6" (152 mm) from top of each pipe (intake and exhaust).

| 2" (51mm) | 3" (76mm) |

| Vent Pipe | Vent Pipe |

A−Minimum clearance | 12" (508MM) | 12" (508MM) |

above grade or average | ||

snow accumulation |

|

|

8 − Based on the recommendation of the manufacturer, a multiple−furnace installation may use a group of up to four terminations assembled together horizontally, as shown in figure 25.

1−1/2" (38mm) accelerator

provided on 71M80 &

44W92 kits for

SLP98DFV−36B−070

B−Maximum horizontal | 6" (152MM) | 6" (152MM) | |

separation between | |||

|

| ||

intake and exhaust |

|

| |

C−Minimum from |

|

| |

end of exhaust to | 6" (152MM) | 6" (152MM) | |

inlet of intake |

|

| |

D−Maximum exhaust | 12" (305MM) | 20" (508MM) | |

pipe length | |||

|

| ||

|

|

| |

E−Maximum wall support |

|

| |

distance from top of each | 6" (152MM) | 6" (152MM) | |

pipe (intake/exhaust) |

|

|

FIGURE 22

12” (305mm)

Minimum

Above Average

Snow

Accumulation

CLAMP

INTAKE | FLASHING |

(Not Furnished) |

SHEET METAL STRAP

(Clamp and sheet metal strap

must be field installed to support the weight of the termination kit.)

FIELD−PROVIDED

REDUCER MAY BE REQUIRED

TO ADAPT LARGER VENT

PIPE SIZE TO TERMINATION

DIRECT VENT CONCENTRIC ROOFTOP TERMINATION

71M80, 69M29 or 60L46 (US) 41W92 or 41W93 (Canada)

FIGURE 23

Page 20