Switches 8 and 9 −− Cooling Mode Blower Speed −− The unit is shipped from the factory with the DIP switches posi- tioned for high speed (4) indoor blower motor operation during the cooling mode. The table below provides the cooling mode blower speeds that will result from different switch settings. Refer to tables beginning on page 37 for corresponding cfm values.

TABLE 18

Cooling Mode Blower Speeds

Speed | Switch 8 | Switch 9 |

1 − Low | On | On |

2 − Medium Low | Off | On |

3 − Medium High | On | Off |

4 − High (Factory) | Off | Off |

Switches 10 and 11 −− Cooling Mode Blower Speed Ad- justment −− The unit is shipped from the factory with the DIP switches positioned for NORMAL (no) adjustment. The DIP switches may be positioned to adjust the blower speed by +10% or −10% to better suit the application. Table 19 provides blower speed adjustments that will result from different switch settings. Refer to tables beginning on page 37 for corresponding cfm values.

With switches 10 and 11 set to ON, motor will bypass ramp- ing profiles and all delays and will immediately run at se- lected COOLING speed upon a call for cool. LED will con- tinue to operate as normal. This mode is used to check motor operation.

TABLE 19

Cooling Mode Blower Speed Adjustment

Adjustment | Switch 10 | Switch 11 |

+10% (approx.) | On | Off |

NORMAL (Factory) | Off | Off |

−10% (approx.) | Off | On |

MOTOR TEST | On | On |

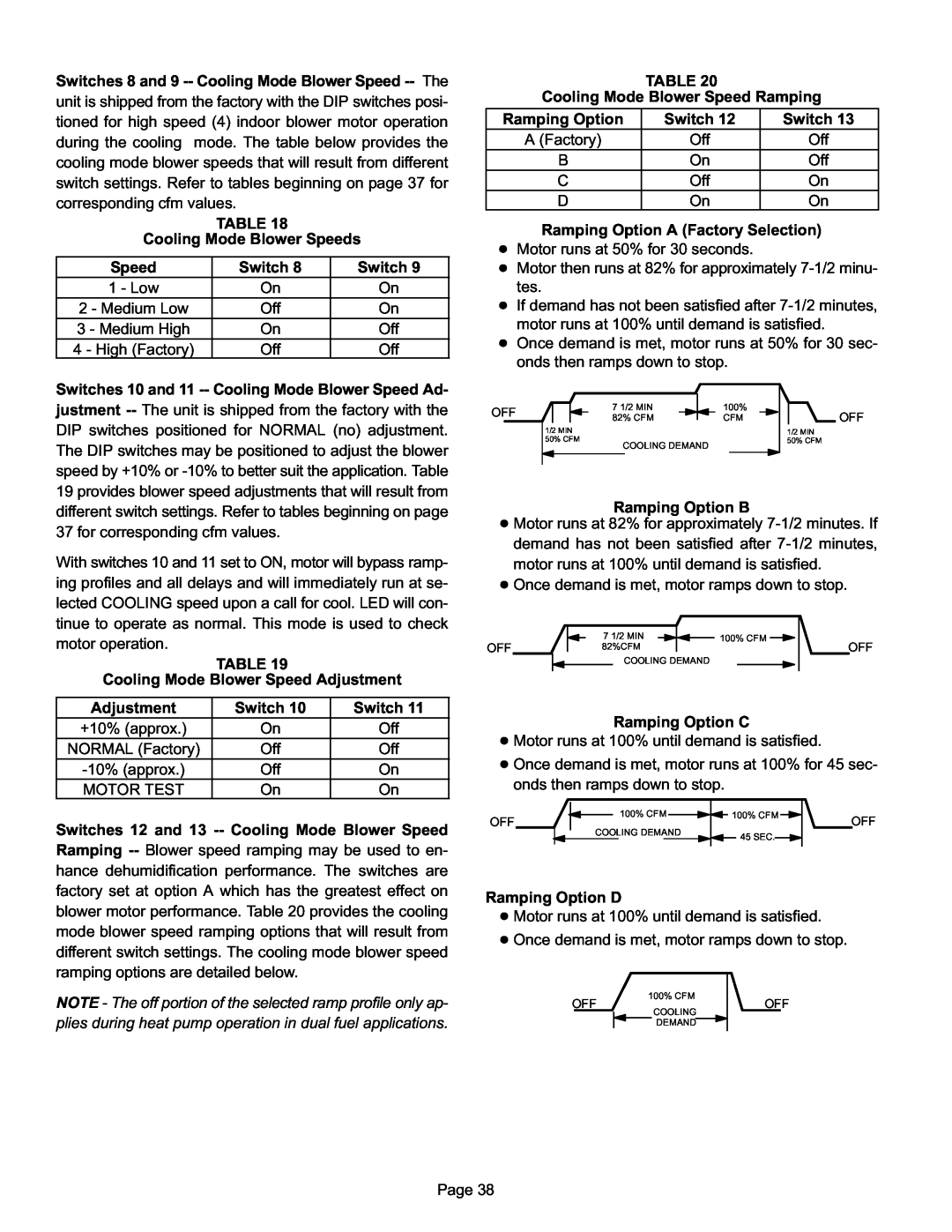

Switches 12 and 13 −− Cooling Mode Blower Speed Ramping −− Blower speed ramping may be used to en- hance dehumidification performance. The switches are factory set at option A which has the greatest effect on blower motor performance. Table 20 provides the cooling mode blower speed ramping options that will result from different switch settings. The cooling mode blower speed ramping options are detailed below.

NOTE − The off portion of the selected ramp profile only ap- plies during heat pump operation in dual fuel applications.

TABLE 20

Cooling Mode Blower Speed Ramping

Ramping Option | Switch 12 | Switch 13 |

A (Factory) | Off | Off |

B | On | Off |

C | Off | On |

D | On | On |

Ramping Option A (Factory Selection)

DMotor runs at 50% for 30 seconds.

DMotor then runs at 82% for approximately 7−1/2 minu- tes.

DIf demand has not been satisfied after 7−1/2 minutes, motor runs at 100% until demand is satisfied.

DOnce demand is met, motor runs at 50% for 30 sec- onds then ramps down to stop.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF |

|

|

|

| 7 1/2 MIN |

|

|

| 100% |

|

|

|

|

| OFF | |||

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

| 82% CFM |

|

| CFM |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

| 1/2 MIN |

|

|

| 1/2 MIN | ||||||||||||

|

| 50% CFM |

|

|

| 50% CFM | ||||||||||||

|

|

|

|

|

| COOLING DEMAND |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ramping Option B

D Motor runs at 82% for approximately 7−1/2 minutes. If demand has not been satisfied after 7−1/2 minutes, motor runs at 100% until demand is satisfied.

D Once demand is met, motor ramps down to stop.

| 7 1/2 MIN | 100% CFM |

|

| |

OFF | 82%CFM | OFF |

| COOLING DEMAND |

|

Ramping Option C

D Motor runs at 100% until demand is satisfied.

D Once demand is met, motor runs at 100% for 45 sec- onds then ramps down to stop.

100% CFM | 100% CFM | OFF |

OFF |

| |

COOLING DEMAND | 45 SEC. |

|

|

|

Ramping Option D

D Motor runs at 100% until demand is satisfied.

D Once demand is met, motor ramps down to stop.

OFF | 100% CFM |

OFF |

COOLING

DEMAND

Page 38