Proper Combustion

Furnace should operate minimum 15 minutes with correct manifold pressure and gas flow rate before checking com- bustion. Take combustion sample beyond the flue outlet and compare to the tables below. The maximum carbon monoxide reading should not exceed 50 ppm.

TABLE 28

High Fire

SLP98DFV Unit |

| CO2% For Nat | CO2% For L.P. |

070V36B |

|

|

|

|

|

|

|

090V36C |

| 7.6 − 8.6 | 9,1 − 10.1 |

|

| ||

090V60C |

| ||

|

|

| |

|

|

|

|

110V60C |

|

|

|

|

|

|

|

| TABLE 29 |

| |

| Low Fire |

| |

Unit |

| CO2% For Nat | CO2% For L.P. |

070V36B |

|

|

|

|

|

|

|

090V36C |

| 5.3 − 6.3 | 6.8 − 7.8 |

|

| ||

090V60C |

| ||

|

|

| |

|

|

|

|

110V60C |

|

|

|

|

|

|

|

Manifold Pressure Measurement

To correctly measure manifold pressure, the differential pressure between the positive gas manifold and the nega- tive burner box must be considered. Use pressure test adapter kit (available as Lennox part 10L34) to assist in measurement.

1 − Remove the threaded plug from the outlet side of the gas valve and install a field−provided barbed fitting. Connect test gauge

measure manifold pressure.

2 − Tee into the gas valve regulator vent hose and connect test gauge

3 − Start unit on low heat (35% rate) and allow 5 minutes for unit to reach steady state.

4 − While waiting for the unit to stabilize, notice the flame. Flame should be stable and should not lift from burner. Natural gas should burn blue.

5 − After allowing unit to stabilize for 5 minutes, record manifold pressure and compare to value given in table 27.

6 − Repeat steps 3, 4 and 5 on high heat.

NOTE − Shut unit off and remove manometer as soon as an accurate reading has been obtained. Take care to remove barbed fitting and replace threaded plug.

![]() CAUTION

CAUTION

Do not attempt to make adjustments to the gas valve.

Other Unit Adjustments

Primary Limit

The primary limit is located on the heating compartment vestibule panel. This limit is factory set and require no ad- justment.

Flame Rollout Switches (Two)

These manually reset switches are located on the burner box.

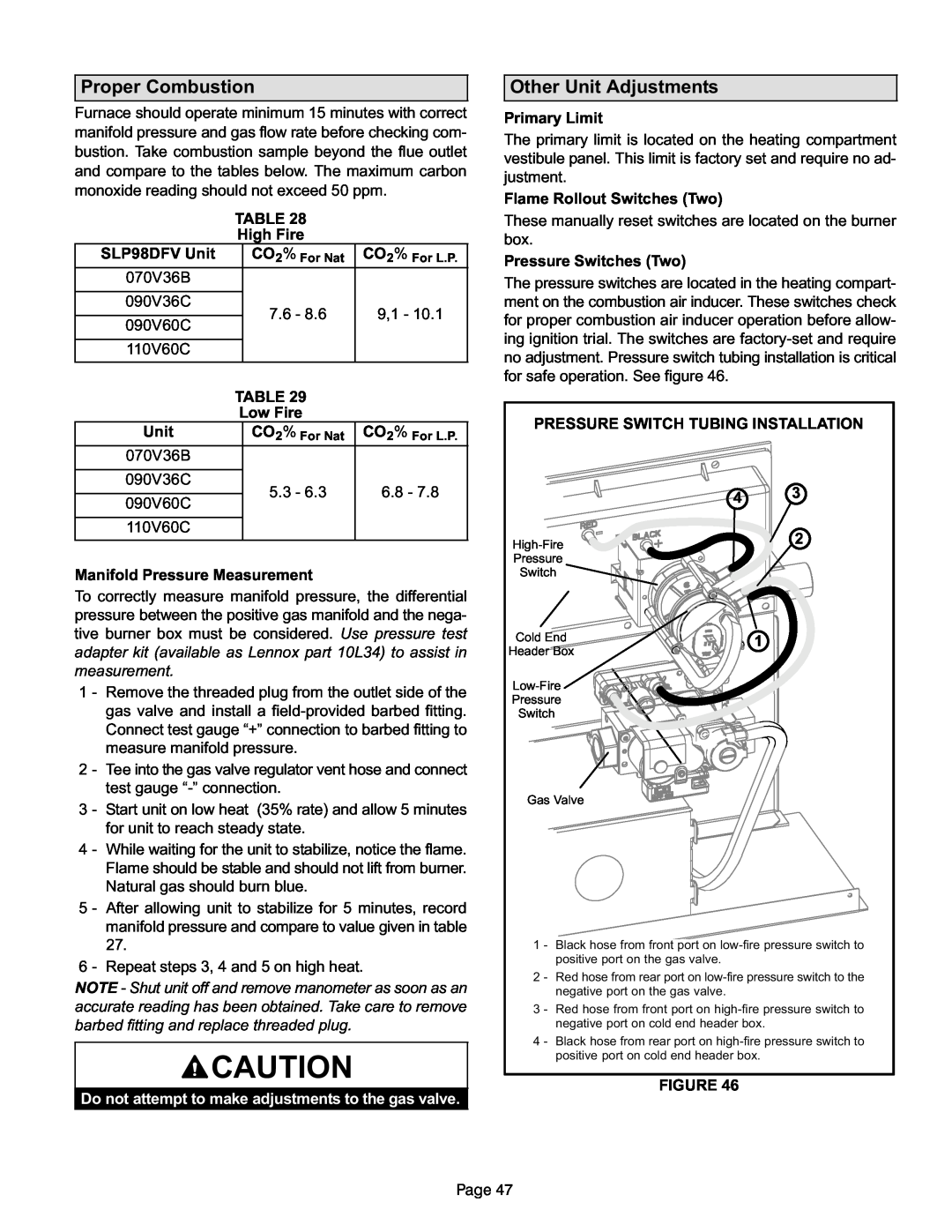

Pressure Switches (Two)

The pressure switches are located in the heating compart- ment on the combustion air inducer. These switches check for proper combustion air inducer operation before allow- ing ignition trial. The switches are factory−set and require no adjustment. Pressure switch tubing installation is critical for safe operation. See figure 46.

PRESSURE SWITCH TUBING INSTALLATION

| 4 | 3 |

|

| |

High−Fire |

| 2 |

|

| |

Pressure |

|

|

Switch |

|

|

Cold End |

| 1 |

Header Box |

| |

|

| |

Low−Fire |

|

|

Pressure |

|

|

Switch |

|

|

Gas Valve

1 − Black hose from front port on low−fire pressure switch to positive port on the gas valve.

2 − Red hose from rear port on low−fire pressure switch to the negative port on the gas valve.

3 − Red hose from front port on high−fire pressure switch to negative port on cold end header box.

4 − Black hose from rear port on high−fire pressure switch to positive port on cold end header box.

FIGURE 46

Page 47