INSTALLATION |

Return to Section TOC

Return to Section TOC

SYSTEM DESCRIPTION

The POWER WAVE 355M/405M and Power Feed 10/11 family of products utilize a digital communication system called Arclink. Simply put, Arclink allows large amounts of information to be passed at very high speeds between components (nodes) in the system. The system requires only two wires for communication, and because of its

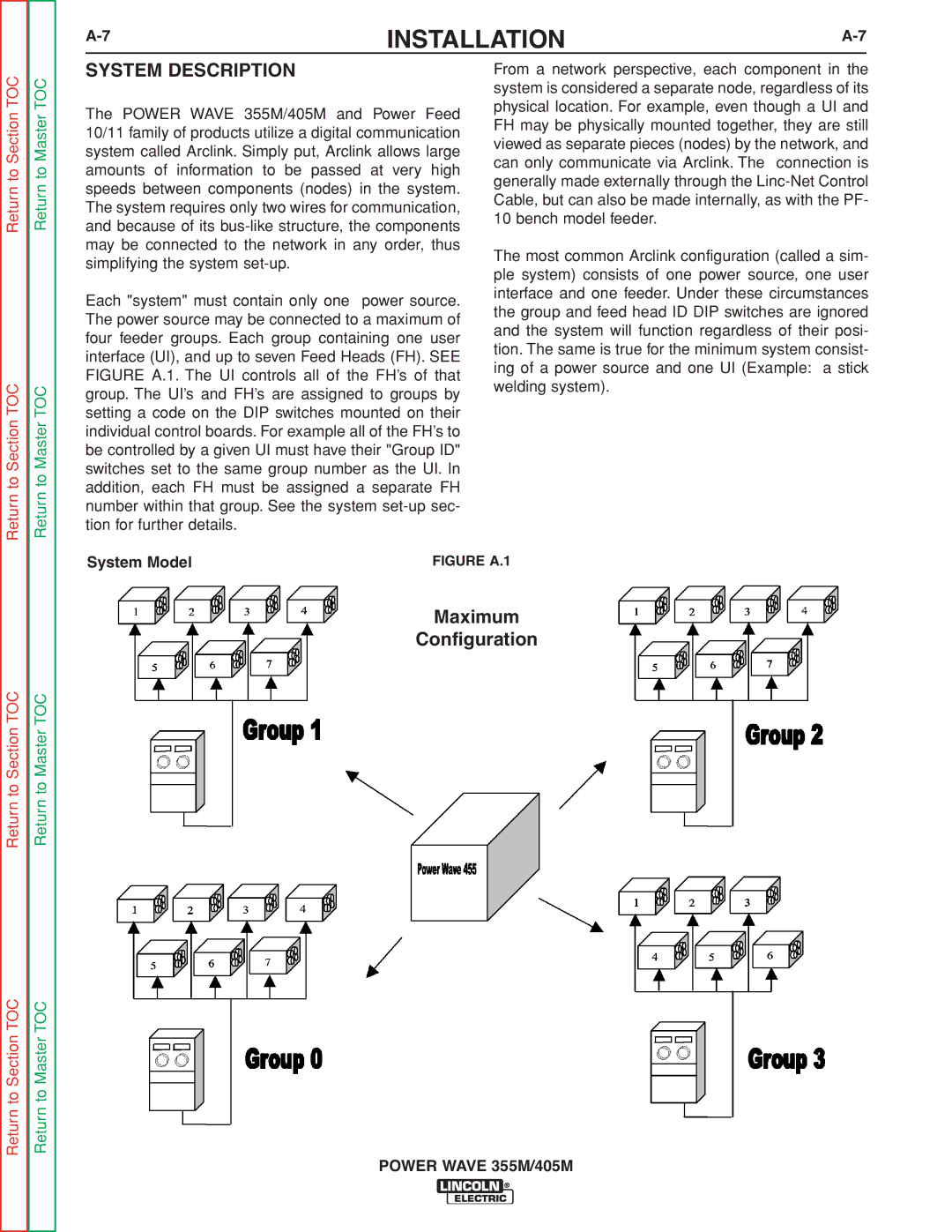

Each "system" must contain only one power source. The power source may be connected to a maximum of four feeder groups. Each group containing one user interface (UI), and up to seven Feed Heads (FH). SEE FIGURE A.1. The UI controls all of the FH’s of that group. The UI’s and FH’s are assigned to groups by setting a code on the DIP switches mounted on their individual control boards. For example all of the FH’s to be controlled by a given UI must have their "Group ID" switches set to the same group number as the UI. In addition, each FH must be assigned a separate FH number within that group. See the system

From a network perspective, each component in the system is considered a separate node, regardless of its physical location. For example, even though a UI and FH may be physically mounted together, they are still viewed as separate pieces (nodes) by the network, and can only communicate via Arclink. The connection is generally made externally through the

The most common Arclink configuration (called a sim- ple system) consists of one power source, one user interface and one feeder. Under these circumstances the group and feed head ID DIP switches are ignored and the system will function regardless of their posi- tion. The same is true for the minimum system consist- ing of a power source and one UI (Example: a stick welding system).

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

System Model | FIGURE A.1 |

Maximum

Configuration

POWER WAVE 355M/405M