OPERATION |

Return to Section TOC

Return to Section TOC

TIG GTAW

The TIG mode features continuous control from 5 to 425 amps. The TIG mode can be run in either the Touch Start TIG or Scratch start mode.

The Arc Control level selects the starting mode.

Between

A setting above 0 selects a Scratch Start. Full OCV is available when the arc initiates the output is regulated to the preset value

Typically starting procedure on a higher “+” setting is known as a “Hot Start”. Setting a starting procedure on a lower setting is known as a “Cold Start”.

NOTE: Later versions of weld software eliminated the Arc Control Function in TIG mode and only allow for “Touch Start” operation.

SMAW

In SMAW (STICK mode), the arc control adjusts the arc force. It can be set to the lower range (0 to

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

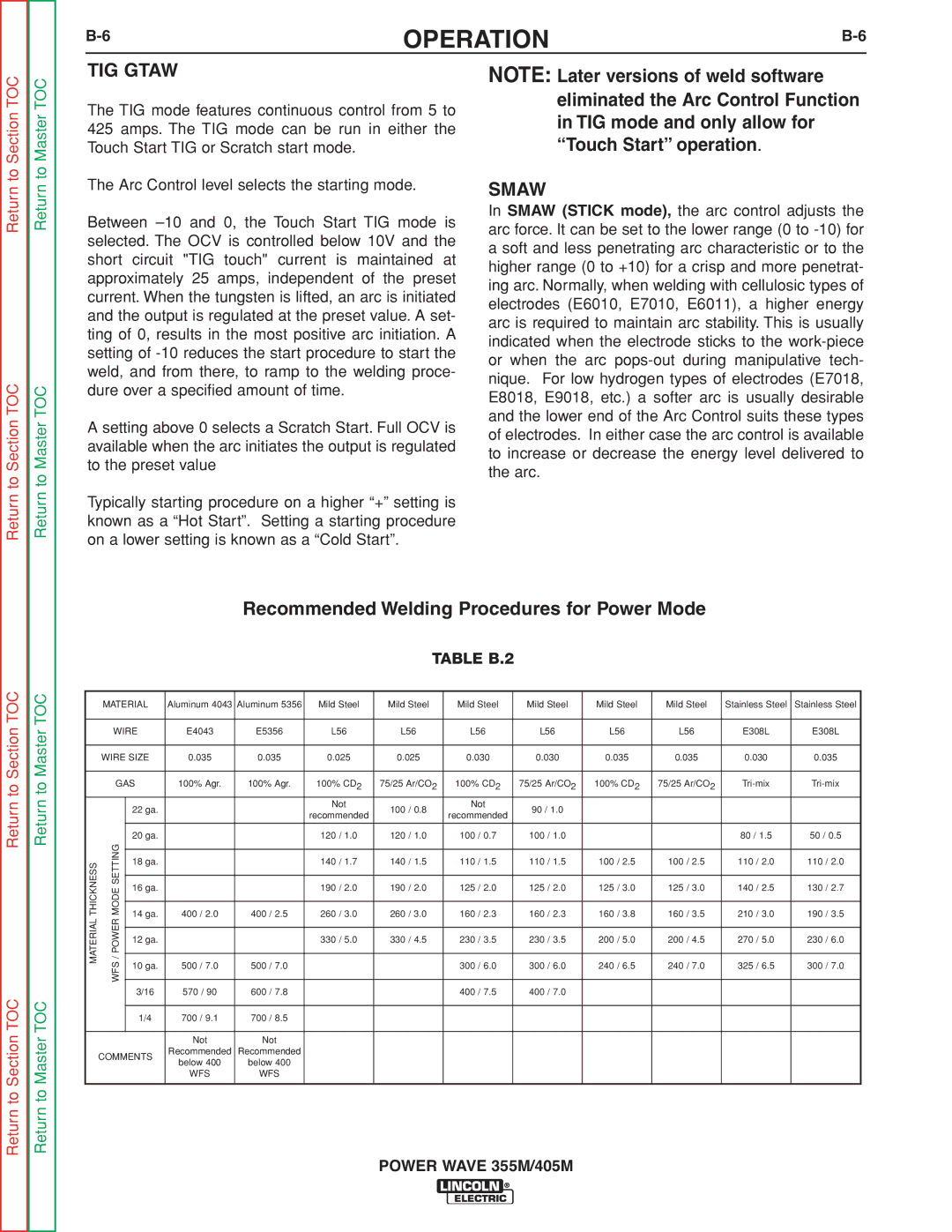

Recommended Welding Procedures for Power Mode

TABLE B.2

| MATERIAL | Aluminum 4043 | Aluminum 5356 | Mild Steel | Mild Steel | Mild Steel | Mild Steel | Mild Steel | Mild Steel | Stainless Steel | Stainless Steel | |

|

|

|

|

|

|

|

|

|

|

|

| |

| WIRE | E4043 | E5356 | L56 | L56 | L56 | L56 | L56 | L56 | E308L | E308L | |

|

|

|

|

|

|

|

|

|

|

|

| |

| WIRE SIZE | 0.035 | 0.035 | 0.025 | 0.025 | 0.030 | 0.030 | 0.035 | 0.035 | 0.030 | 0.035 | |

|

|

|

|

|

|

|

|

|

|

|

| |

| GAS | 100% Agr. | 100% Agr. | 100% CD2 | 75/25 Ar/CO2 | 100% CD2 | 75/25 Ar/CO2 | 100% CD2 | 75/25 Ar/CO2 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 ga. |

|

| Not | 100 / 0.8 | Not | 90 / 1.0 |

|

|

|

|

|

|

|

| recommended | recommended |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 ga. |

|

| 120 / 1.0 | 120 / 1.0 | 100 / 0.7 | 100 / 1.0 |

|

| 80 / 1.5 | 50 / 0.5 |

THICKNESS | SETTINGMODE |

|

|

|

|

|

|

|

|

|

|

|

18 ga. |

|

| 140 / 1.7 | 140 / 1.5 | 110 / 1.5 | 110 / 1.5 | 100 / 2.5 | 100 / 2.5 | 110 / 2.0 | 110 / 2.0 | ||

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 16 ga. |

|

| 190 / 2.0 | 190 / 2.0 | 125 / 2.0 | 125 / 2.0 | 125 / 3.0 | 125 / 3.0 | 140 / 2.5 | 130 / 2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIAL | POWER/WFS | 14 ga. | 400 / 2.0 | 400 / 2.5 | 260 / 3.0 | 260 / 3.0 | 160 / 2.3 | 160 / 2.3 | 160 / 3.8 | 160 / 3.5 | 210 / 3.0 | 190 / 3.5 |

|

|

|

|

|

|

|

|

|

|

| ||

12 ga. |

|

| 330 / 5.0 | 330 / 4.5 | 230 / 3.5 | 230 / 3.5 | 200 / 5.0 | 200 / 4.5 | 270 / 5.0 | 230 / 6.0 | ||

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10 ga. | 500 / 7.0 | 500 / 7.0 |

|

| 300 / 6.0 | 300 / 6.0 | 240 / 6.5 | 240 / 7.0 | 325 / 6.5 | 300 / 7.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3/16 | 570 / 90 | 600 / 7.8 |

|

| 400 / 7.5 | 400 / 7.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/4 | 700 / 9.1 | 700 / 8.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Not | Not |

|

|

|

|

|

|

|

|

| COMMENTS | Recommended | Recommended |

|

|

|

|

|

|

|

| |

| below 400 | below 400 |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| WFS | WFS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POWER WAVE 355M/405M