INSTALLATION |

Return to Section TOC

Section TOC

CABLE INDUCTANCE, AND ITS EFFECTS ON PULSE WELDING

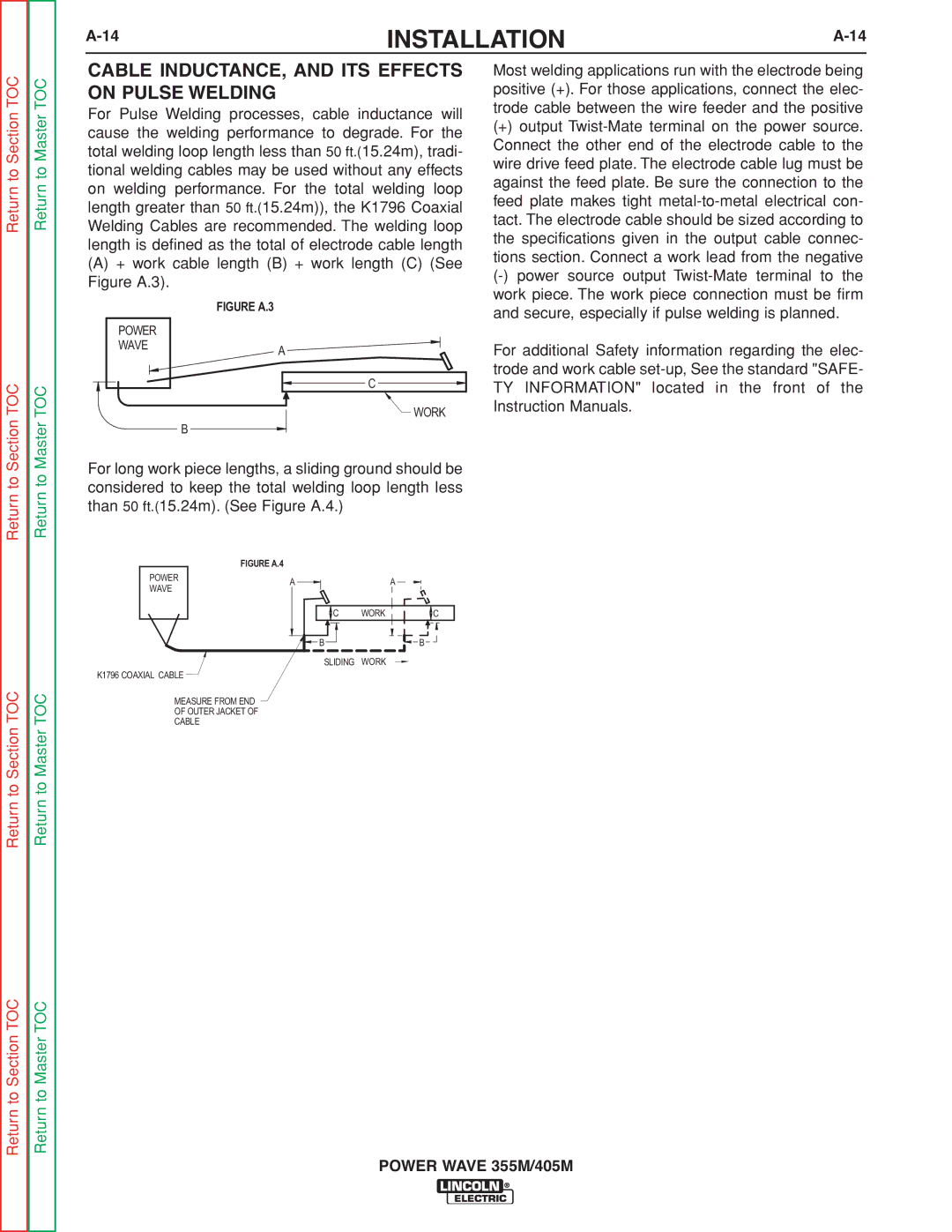

For Pulse Welding processes, cable inductance will cause the welding performance to degrade. For the total welding loop length less than 50 ft.(15.24m), tradi- tional welding cables may be used without any effects on welding performance. For the total welding loop length greater than 50 ft.(15.24m)), the K1796 Coaxial Welding Cables are recommended. The welding loop length is defined as the total of electrode cable length

(A)+ work cable length (B) + work length (C) (See Figure A.3).

POWER |

| FIGURE A.3 |

| A | |

WAVE |

| |

|

| C |

| B | WORK |

|

|

Most welding applications run with the electrode being positive (+). For those applications, connect the elec- trode cable between the wire feeder and the positive

(+)output

For additional Safety information regarding the elec- trode and work cable

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

For long work piece lengths, a sliding ground should be considered to keep the total welding loop length less than 50 ft.(15.24m). (See Figure A.4.)

POWER | FIGURE A.4 | A |

| A |

|

| |||

WAVE |

|

|

|

|

|

| C | WORK | C |

|

| B | WORK | B |

K1796 COAXIAL CABLE |

| SLIDING |

| |

|

|

|

| |

MEASURE FROM END |

|

|

| |

OF OUTER JACKET OF |

|

|

| |

CABLE |

|

|

|

|

POWER WAVE 355M/405M