Return to Master TOC

Return to Master TOC

to Master TOC

| OPERATION | |||||

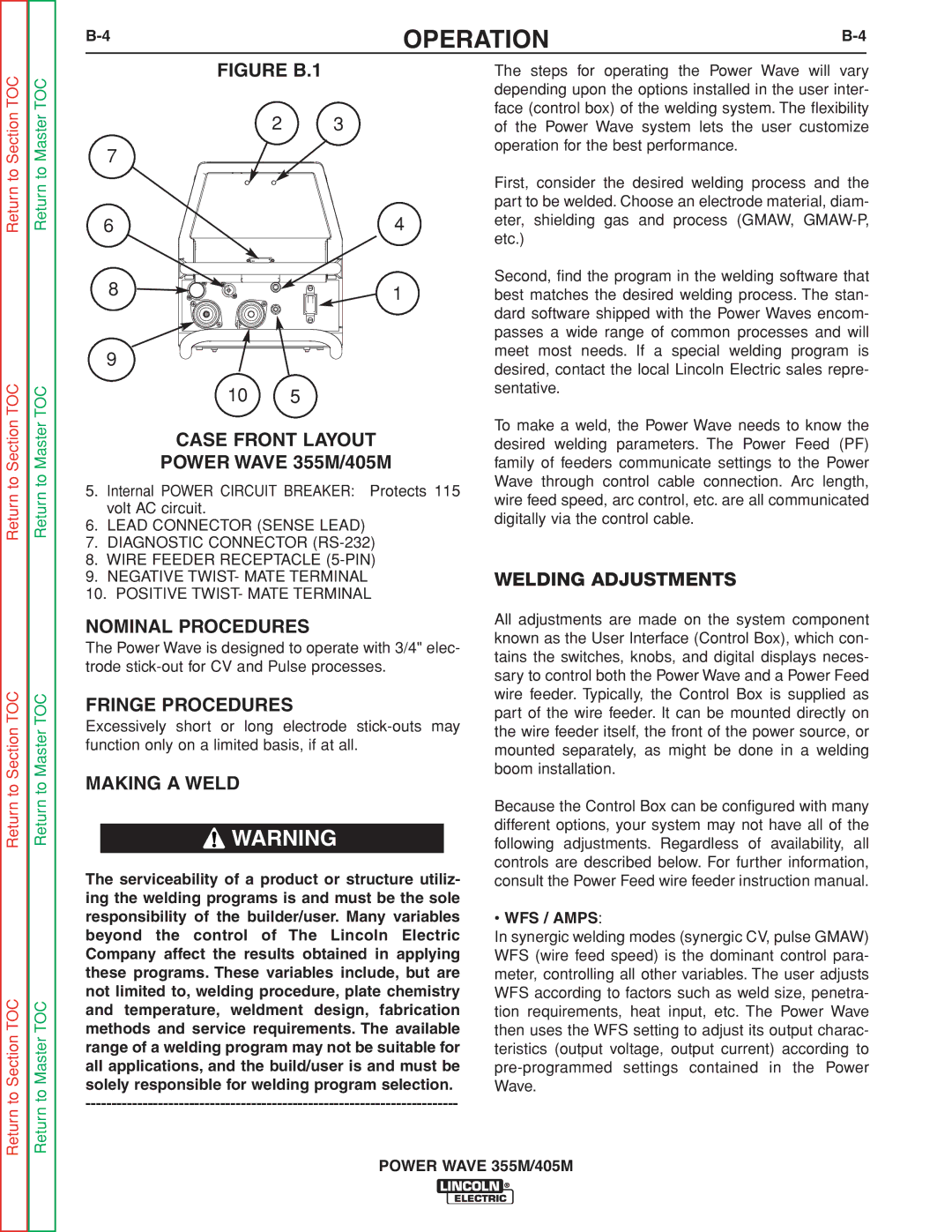

FIGURE B.1 |

|

| The steps for operating the Power Wave will vary | |||

|

|

|

| depending upon the options installed in the user inter- | ||

2 | 3 |

|

| face (control box) of the welding system. The flexibility | ||

|

| of the Power Wave system lets the user customize | ||||

7 |

|

|

| operation for the best performance. |

| |

|

|

|

|

| ||

|

|

|

| First, consider the desired welding process and the | ||

|

|

|

| part to be welded. Choose an electrode material, diam- | ||

6 |

| 4 |

| eter, shielding gas and process (GMAW, | ||

|

|

|

| etc.) |

| |

8 |

| 1 |

| Second, find the program in the welding software that | ||

|

| best matches the desired welding process. The stan- | ||||

|

|

|

| dard software shipped with the Power Waves encom- | ||

|

|

|

| passes a wide range of common processes and will | ||

9 |

|

|

| meet most needs. If a special welding | program is | |

|

|

| desired, contact the local Lincoln Electric sales repre- | |||

|

|

|

| |||

10 | 5 |

|

| sentative. |

| |

|

|

|

| |||

CASE FRONT LAYOUT |

|

| To make a weld, the Power Wave needs to know the | |||

|

| desired welding parameters. The Power Feed (PF) | ||||

POWER WAVE 355M/405M |

|

| family of feeders communicate settings to the Power | |||

5. Internal POWER CIRCUIT BREAKER: Protects 115 | Wave through control cable connection. Arc length, | |||||

wire feed speed, arc control, etc. are all communicated | ||||||

volt AC circuit. |

|

|

| |||

|

|

| digitally via the control cable. |

| ||

6. LEAD CONNECTOR (SENSE LEAD) |

|

|

| |||

|

|

|

| |||

7. DIAGNOSTIC CONNECTOR |

|

|

|

| ||

8. WIRE FEEDER RECEPTACLE |

|

|

|

| ||

9. NEGATIVE TWIST- MATE TERMINAL |

|

| WELDING ADJUSTMENTS |

| ||

10. POSITIVE TWIST- MATE TERMINAL |

|

|

|

| ||

NOMINAL PROCEDURES |

|

| All adjustments are made on the system component | |||

|

| known as the User Interface (Control Box), which con- | ||||

The Power Wave is designed to operate with 3/4" elec- | ||||||

tains the switches, knobs, and digital displays neces- | ||||||

trode |

|

| ||||

|

| sary to control both the Power Wave and a Power Feed | ||||

|

|

|

| |||

FRINGE PROCEDURES |

|

| wire feeder. Typically, the Control Box is supplied as | |||

|

| part of the wire feeder. It can be mounted directly on | ||||

Excessively short or long | electrode | may | ||||

the wire feeder itself, the front of the power source, or | ||||||

|

|

|

| |||

function only on a limited basis, if at all. | mounted separately, as might be done in a welding |

| |

MAKING A WELD | boom installation. |

|

Return

to Section TOC

Return

Return to Master TOC

![]() WARNING

WARNING

The serviceability of a product or structure utiliz- ing the welding programs is and must be the sole responsibility of the builder/user. Many variables beyond the control of The Lincoln Electric Company affect the results obtained in applying these programs. These variables include, but are not limited to, welding procedure, plate chemistry and temperature, weldment design, fabrication methods and service requirements. The available range of a welding program may not be suitable for all applications, and the build/user is and must be solely responsible for welding program selection.

Because the Control Box can be configured with many different options, your system may not have all of the following adjustments. Regardless of availability, all controls are described below. For further information, consult the Power Feed wire feeder instruction manual.

•WFS / AMPS:

In synergic welding modes (synergic CV, pulse GMAW) WFS (wire feed speed) is the dominant control para- meter, controlling all other variables. The user adjusts WFS according to factors such as weld size, penetra- tion requirements, heat input, etc. The Power Wave then uses the WFS setting to adjust its output charac- teristics (output voltage, output current) according to

Return

POWER WAVE 355M/405M