Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

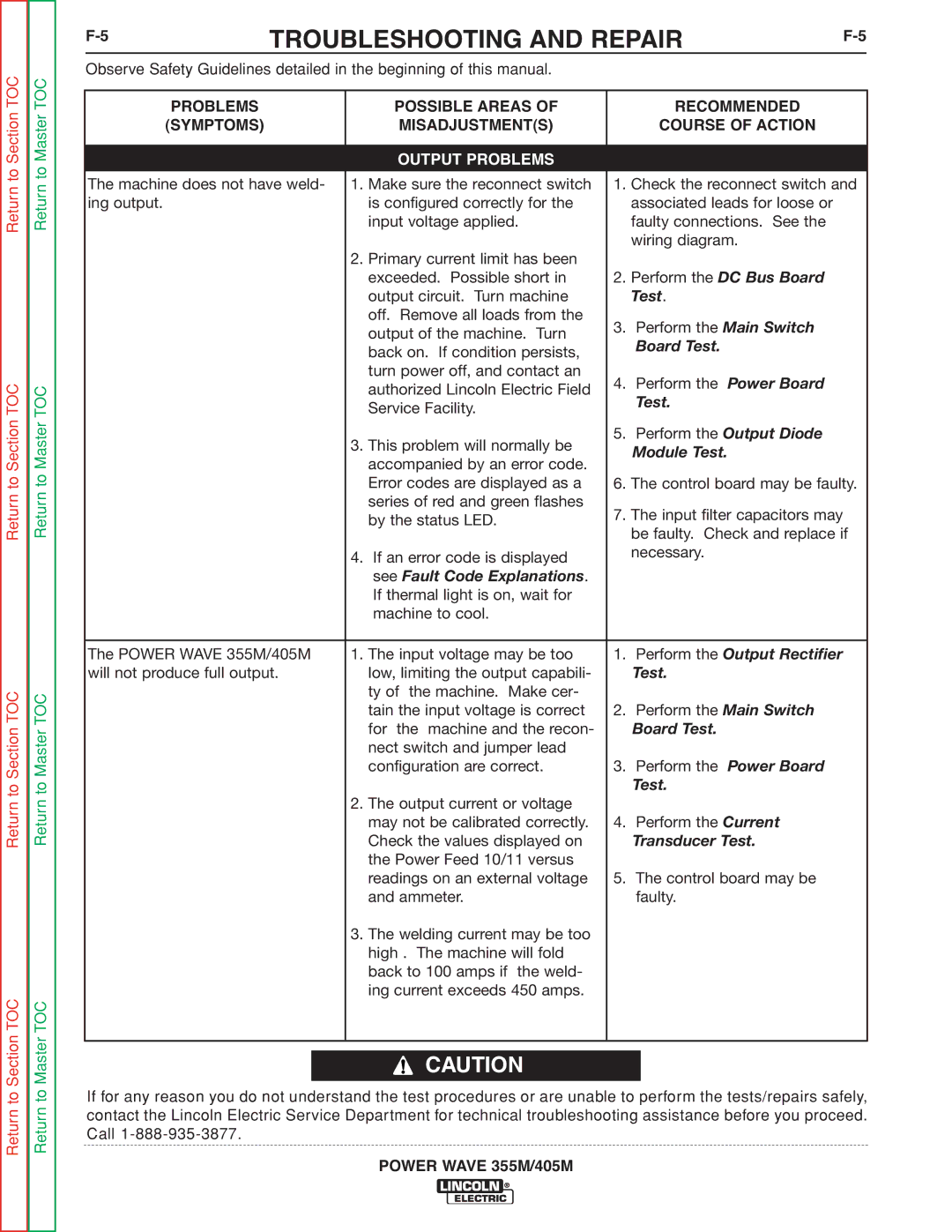

TROUBLESHOOTING AND REPAIR |

| ||||||

Observe Safety Guidelines detailed in the beginning of this manual. |

|

|

|

| |||

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

| |

|

|

|

| ||||

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

| |

|

|

| OUTPUT PROBLEMS |

|

|

|

|

|

|

|

|

|

|

| |

The machine does not have weld- |

| 1. Make sure the reconnect switch | 1. | Check the reconnect switch and |

| ||

ing output. |

|

| is configured correctly for the |

| associated leads for loose or |

| |

|

|

| input voltage applied. |

| faulty connections. See the |

| |

|

|

|

|

| wiring diagram. |

| |

|

|

| 2. Primary current limit has been |

|

|

|

|

|

|

| exceeded. Possible short in | 2. | Perform the DC Bus Board |

| |

|

|

| output circuit. Turn machine |

| Test. |

|

|

|

|

| off. Remove all loads from the | 3. | Perform the Main Switch |

| |

|

|

| output of the machine. Turn |

| |||

|

|

|

| Board Test. |

|

| |

|

|

| back on. If condition persists, |

|

|

| |

|

|

|

|

|

|

| |

|

|

| turn power off, and contact an | 4. | Perform the | Power Board |

|

|

|

| authorized Lincoln Electric Field |

| |||

|

|

|

| Test. |

|

| |

|

|

| Service Facility. |

|

|

| |

|

|

|

|

|

|

| |

|

|

| 3. This problem will normally be | 5. | Perform the Output Diode |

| |

|

|

|

| Module Test. |

| ||

|

|

| accompanied by an error code. |

|

| ||

|

|

|

|

|

|

| |

|

|

| Error codes are displayed as a | 6. | The control board may be faulty. |

| |

|

|

| series of red and green flashes | 7. | The input filter capacitors may |

| |

|

|

| by the status LED. |

| |||

|

|

|

| be faulty. Check and replace if |

| ||

|

|

|

|

|

| ||

|

|

| 4. If an error code is displayed |

| necessary. |

|

|

|

|

|

|

|

|

| |

|

|

| see Fault Code Explanations. |

|

|

|

|

|

|

| If thermal light is on, wait for |

|

|

|

|

|

|

| machine to cool. |

|

|

|

|

|

|

|

|

|

| ||

The POWER WAVE 355M/405M |

| 1. The input voltage may be too | 1. | Perform the Output Rectifier |

| ||

will not produce full output. |

| low, limiting the output capabili- |

| Test. |

|

| |

|

|

| ty of the machine. Make cer- |

|

|

|

|

|

|

| tain the input voltage is correct | 2. | Perform the Main Switch |

| |

|

|

| for the machine and the recon- |

| Board Test. |

|

|

|

|

| nect switch and jumper lead |

|

|

|

|

|

|

| configuration are correct. | 3. | Perform the | Power Board |

|

|

|

|

|

| Test. |

|

|

|

|

| 2. The output current or voltage |

|

|

|

|

|

|

| may not be calibrated correctly. | 4. | Perform the Current |

| |

|

|

| Check the values displayed on |

| Transducer Test. |

| |

|

|

| the Power Feed 10/11 versus |

|

|

|

|

|

|

| readings on an external voltage | 5. | The control board may be |

| |

|

|

| and ammeter. |

| faulty. |

|

|

|

|

| 3. The welding current may be too |

|

|

|

|

|

|

| high . The machine will fold |

|

|

|

|

|

|

| back to 100 amps if the weld- |

|

|

|

|

|

|

| ing current exceeds 450 amps. |

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call