INPUT CONNECTIONS

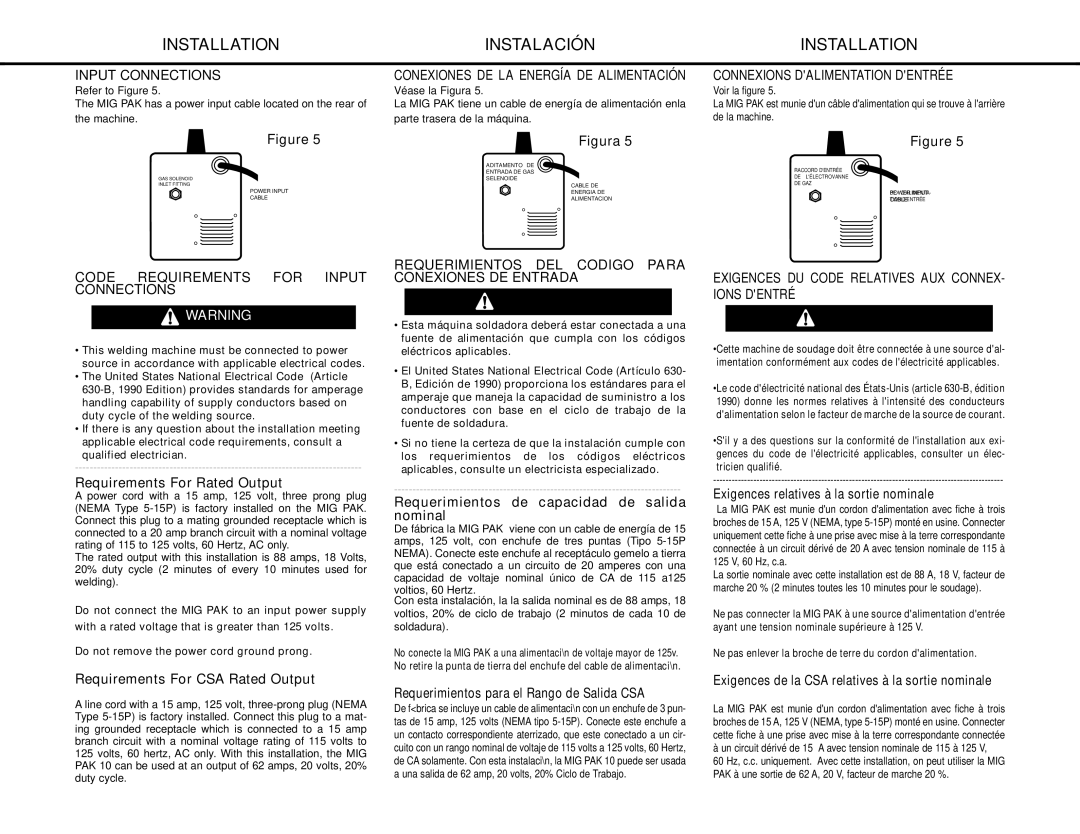

Refer to Figure 5.

The MIG PAK has a power input cable located on the rear of the machine.

Figure 5

GAS SOLENOID

INLET FITTING

POWER INPUT

CABLE

CODE REQUIREMENTS FOR INPUT CONNECTIONS

WARNING

WARNING

•This welding machine must be connected to power source in accordance with applicable electrical codes.

•The United States National Electrical Code (Article 630-B, 1990 Edition) provides standards for amperage handling capability of supply conductors based on duty cycle of the welding source.

•If there is any question about the installation meeting applicable electrical code requirements, consult a

qualified electrician.

-------------------------------------------------------------------------------

Requirements For Rated Output

A power cord with a 15 amp, 125 volt, three prong plug (NEMA Type 5-15P) is factory installed on the MIG PAK. Connect this plug to a mating grounded receptacle which is connected to a 20 amp branch circuit with a nominal voltage rating of 115 to 125 volts, 60 Hertz, AC only.

The rated output with this installation is 88 amps, 18 Volts, 20% duty cycle (2 minutes of every 10 minutes used for welding).

Do not connect the MIG PAK to an input power supply with a rated voltage that is greater than 125 volts.

Do not remove the power cord ground prong.

Requirements For CSA Rated Output

A line cord with a 15 amp, 125 volt, three-prong plug (NEMA Type 5-15P) is factory installed. Connect this plug to a mat- ing grounded receptacle which is connected to a 15 amp branch circuit with a nominal voltage rating of 115 volts to 125 volts, 60 hertz, AC only. With this installation, the MIG PAK 10 can be used at an output of 62 amps, 20 volts, 20% duty cycle.

CONEXIONES DE LA ENERGÍA DE ALIMENTACIÓN

Véase la Figura 5.

La MIG PAK tiene un cable de energía de alimentación enla

parte trasera de la máquina.

Figura 5

ADITAMENTO DE

ENTRADA DE GAS

SELENOIDE

CABLE DE

ENERGIA DE

ALIMENTACION

REQUERIMIENTOS DEL CODIGO PARA CONEXIONES DE ENTRADA

ADVERTENCIA

ADVERTENCIA

•Esta máquina soldadora deberá estar conectada a una fuente de alimentación que cumpla con los códigos eléctricos aplicables.

•El United States National Electrical Code (Artículo 630- B, Edición de 1990) proporciona los estándares para el amperaje que maneja la capacidad de suministro a los conductores con base en el ciclo de trabajo de la fuente de soldadura.

•Si no tiene la certeza de que la instalación cumple con los requerimientos de los códigos eléctricos aplicables, consulte un electricista especializado.

-------------------------------------------------------------------------------

Requerimientos de capacidad de salida nominal

De fábrica la MIG PAK viene con un cable de energía de 15 amps, 125 volt, con enchufe de tres puntas (Tipo 5-15P NEMA). Conecte este enchufe al receptáculo gemelo a tierra que está conectado a un circuito de 20 amperes con una capacidad de voltaje nominal único de CA de 115 a125

voltios, 60 Hertz.

Con esta instalación, la la salida nominal es de 88 amps, 18 voltios, 20% de ciclo de trabajo (2 minutos de cada 10 de soldadura).

No conecte la MIG PAK a una alimentaci\n de voltaje mayor de 125v. No retire la punta de tierra del enchufe del cable de alimentaci\n.

Requerimientos para el Rango de Salida CSA

De f<brica se incluye un cable de alimentaci\n con un enchufe de 3 pun- tas de 15 amp, 125 volts (NEMA tipo 5-15P). Conecte este enchufe a un contacto correspondiente aterrizado, que este conectado a un cir- cuito con un rango nominal de voltaje de 115 volts a 125 volts, 60 Hertz, de CA solamente. Con esta instalaci\n, la MIG PAK 10 puede ser usada a una salida de 62 amp, 20 volts, 20% Ciclo de Trabajo.

CONNEXIONS D'ALIMENTATION D'ENTRÉE

Voir la figure 5.

La MIG PAK est munie d'un câble d'alimentation qui se trouve à l'arrière de la machine.

Figure 5

RACCORD D'ENTRÉE

DE L'ÉLECTROVANNE

DE GAZ

BE D'ALIMENTA-

TION D'ENTRÉE

EXIGENCES DU CODE RELATIVES AUX CONNEX- IONS D'ENTRÉ

AVERTISSEMENT

AVERTISSEMENT

•Cette machine de soudage doit être connectée à une source d'al- imentation conformément aux codes de l'électricité applicables.

•Le code d'électricité national des États-Unis (article 630-B, édition 1990) donne les normes relatives à l'intensité des conducteurs d'alimentation selon le facteur de marche de la source de courant.

•S'il y a des questions sur la conformité de l'installation aux exi- gences du code de l'électricité applicables, consulter un élec- tricien qualifié.

----------------------------------------------------------------------------------------------

Exigences relatives à la sortie nominale

La MIG PAK est munie d'un cordon d'alimentation avec fiche à trois broches de 15 A, 125 V (NEMA, type 5-15P) monté en usine. Connecter uniquement cette fiche à une prise avec mise à la terre correspondante connectée à un circuit dérivé de 20 A avec tension nominale de 115 à 125 V, 60 Hz, c.a.

La sortie nominale avec cette installation est de 88 A, 18 V, facteur de marche 20 % (2 minutes toutes les 10 minutes pour le soudage).

Ne pas connecter la MIG PAK à une source d'alimentation d'entrée ayant une tension nominale supérieure à 125 V.

Ne pas enlever la broche de terre du cordon d'alimentation.

Exigences de la CSA relatives à la sortie nominale

La MIG PAK est munie d'un cordon d'alimentation avec fiche à trois broches de 15 A, 125 V (NEMA, type 5-15P) monté en usine. Connecter cette fiche à une prise avec mise à la terre correspondante connectée

àun circuit dérivé de 15 A avec tension nominale de 115 à 125 V,

60 Hz, c.c. uniquement. Avec cette installation, on peut utiliser la MIG PAK à une sortie de 62 A, 20 V, facteur de marche 20 %.