LEARNING TO WELD

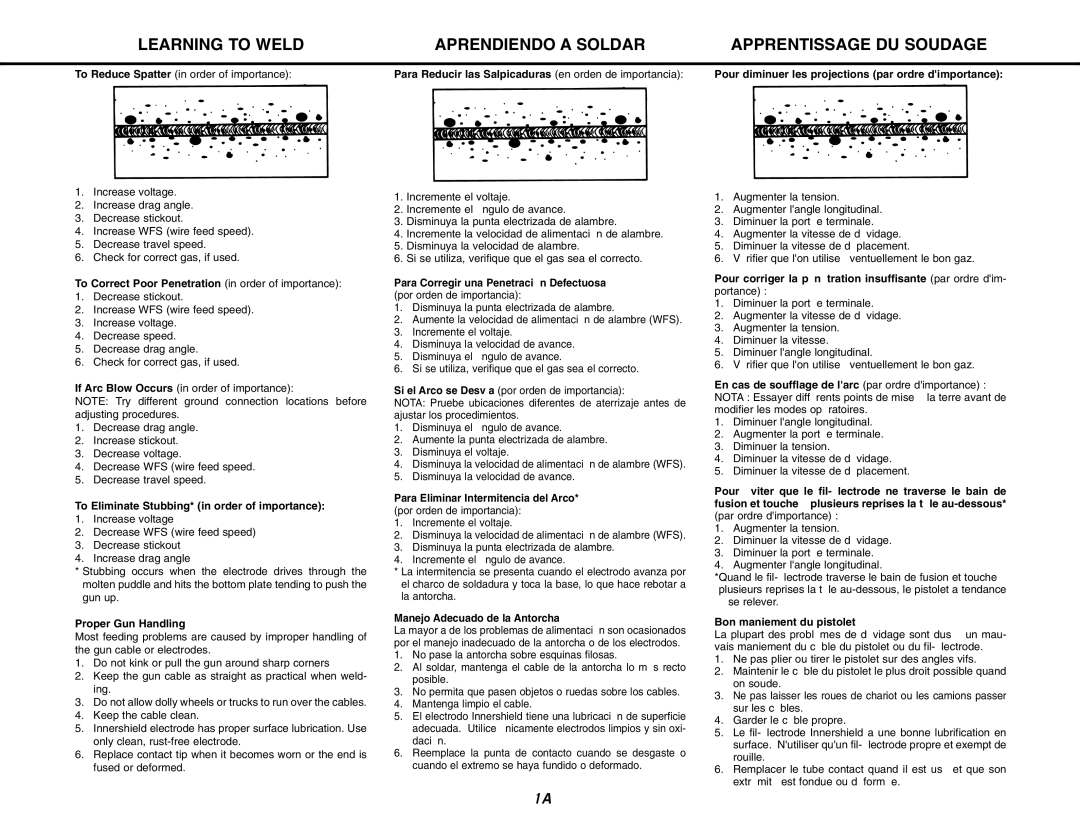

To Reduce Spatter (in order of importance):

1.Increase voltage.

2.Increase drag angle.

3.Decrease stickout.

4.Increase WFS (wire feed speed).

5.Decrease travel speed.

6.Check for correct gas, if used.

To Correct Poor Penetration (in order of importance):

1.Decrease stickout.

2.Increase WFS (wire feed speed).

3.Increase voltage.

4.Decrease speed.

5.Decrease drag angle.

6.Check for correct gas, if used.

If Arc Blow Occurs (in order of importance):

NOTE: Try different ground connection locations before adjusting procedures.

1.Decrease drag angle.

2.Increase stickout.

3.Decrease voltage.

4.Decrease WFS (wire feed speed.

5.Decrease travel speed.

To Eliminate Stubbing* (in order of importance):

1.Increase voltage

2.Decrease WFS (wire feed speed)

3.Decrease stickout

4.Increase drag angle

*Stubbing occurs when the electrode drives through the molten puddle and hits the bottom plate tending to push the gun up.

Proper Gun Handling

Most feeding problems are caused by improper handling of the gun cable or electrodes.

1.Do not kink or pull the gun around sharp corners

2.Keep the gun cable as straight as practical when weld- ing.

3.Do not allow dolly wheels or trucks to run over the cables.

4.Keep the cable clean.

5.Innershield electrode has proper surface lubrication. Use only clean, rust-free electrode.

6.Replace contact tip when it becomes worn or the end is fused or deformed.

APRENDIENDO A SOLDAR

Para Reducir las Salpicaduras (en orden de importancia):

1.Incremente el voltaje.

2.Incremente el ángulo de avance.

3.Disminuya la punta electrizada de alambre.

4.Incremente la velocidad de alimentación de alambre.

5.Disminuya la velocidad de alambre.

6.Si se utiliza, verifique que el gas sea el correcto.

Para Corregir una Penetración Defectuosa (por orden de importancia):

1.Disminuya la punta electrizada de alambre.

2.Aumente la velocidad de alimentación de alambre (WFS).

3.Incremente el voltaje.

4.Disminuya la velocidad de avance.

5.Disminuya el ángulo de avance.

6.Si se utiliza, verifique que el gas sea el correcto.

Si el Arco se Desvía (por orden de importancia):

NOTA: Pruebe ubicaciones diferentes de aterrizaje antes de ajustar los procedimientos.

1.Disminuya el ángulo de avance.

2.Aumente la punta electrizada de alambre.

3.Disminuya el voltaje.

4.Disminuya la velocidad de alimentación de alambre (WFS).

5.Disminuya la velocidad de avance.

Para Eliminar Intermitencia del Arco*

(por orden de importancia):

1.Incremente el voltaje.

2.Disminuya la velocidad de alimentación de alambre (WFS).

3.Disminuya la punta electrizada de alambre.

4.Incremente el ángulo de avance.

*La intermitencia se presenta cuando el electrodo avanza por el charco de soldadura y toca la base, lo que hace rebotar a la antorcha.

Manejo Adecuado de la Antorcha

La mayoría de los problemas de alimentación son ocasionados por el manejo inadecuado de la antorcha o de los electrodos.

1.No pase la antorcha sobre esquinas filosas.

2.Al soldar, mantenga el cable de la antorcha lo más recto posible.

3.No permita que pasen objetos o ruedas sobre los cables.

4.Mantenga limpio el cable.

5.El electrodo Innershield tiene una lubricación de superficie adecuada. Utilice únicamente electrodos limpios y sin oxi- dación.

6.Reemplace la punta de contacto cuando se desgaste o cuando el extremo se haya fundido o deformado.

APPRENTISSAGE DU SOUDAGE

Pour diminuer les projections (par ordre d'importance):

1.Augmenter la tension.

2.Augmenter l'angle longitudinal.

3.Diminuer la portée terminale.

4.Augmenter la vitesse de dévidage.

5.Diminuer la vitesse de déplacement.

6.Vérifier que l'on utilise éventuellement le bon gaz.

Pour corriger la pénétration insuffisante (par ordre d'im- portance) :

1.Diminuer la portée terminale.

2.Augmenter la vitesse de dévidage.

3.Augmenter la tension.

4.Diminuer la vitesse.

5.Diminuer l'angle longitudinal.

6.Vérifier que l'on utilise éventuellement le bon gaz.

En cas de soufflage de l'arc (par ordre d'importance) : NOTA : Essayer différents points de mise à la terre avant de modifier les modes opératoires.

1.Diminuer l'angle longitudinal.

2.Augmenter la portée terminale.

3.Diminuer la tension.

4.Diminuer la vitesse de dévidage.

5.Diminuer la vitesse de déplacement.

Pour éviter que le fil-électrode ne traverse le bain de fusion et touche à plusieurs reprises la tôle au-dessous* (par ordre d'importance) :

1.Augmenter la tension.

2.Diminuer la vitesse de dévidage.

3.Diminuer la portée terminale.

4.Augmenter l'angle longitudinal.

*Quand le fil-électrode traverse le bain de fusion et touche à plusieurs reprises la tôle au-dessous, le pistolet a tendance

àse relever.

Bon maniement du pistolet

La plupart des problèmes de dévidage sont dus à un mau- vais maniement du câble du pistolet ou du fil-électrode.

1.Ne pas plier ou tirer le pistolet sur des angles vifs.

2.Maintenir le câble du pistolet le plus droit possible quand on soude.

3.Ne pas laisser les roues de chariot ou les camions passer sur les câbles.

4.Garder le câble propre.

5.Le fil-électrode Innershield a une bonne lubrification en surface. N'utiliser qu'un fil-électrode propre et exempt de rouille.

6.Remplacer le tube contact quand il est usé et que son extrémité est fondue ou déformée.