Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

OPERATION |

ALUMINUM GMAW-P AND GMAW-PP

ALUMINUM PULSE WELDING

Synergic

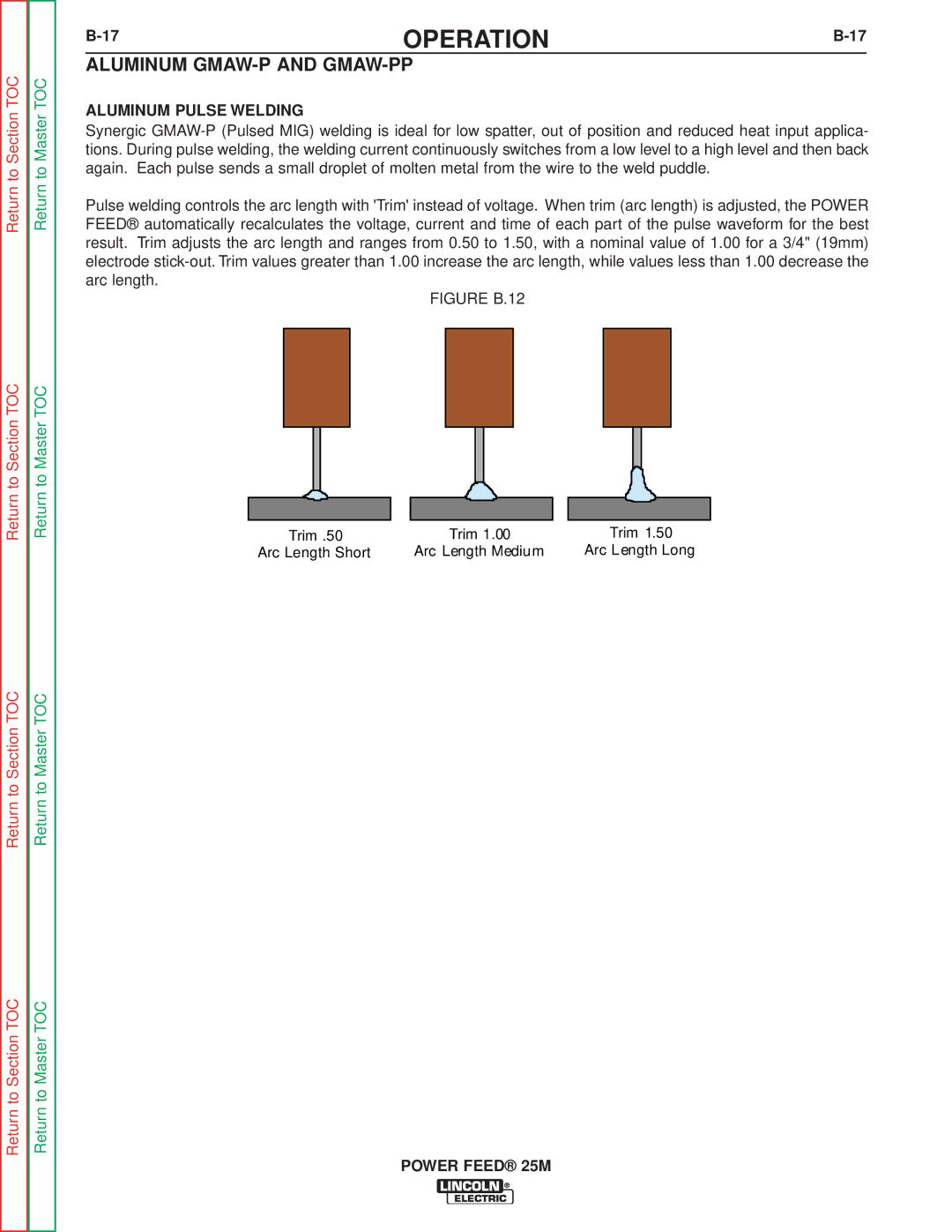

Pulse welding controls the arc length with 'Trim' instead of voltage. When trim (arc length) is adjusted, the POWER FEED® automatically recalculates the voltage, current and time of each part of the pulse waveform for the best result. Trim adjusts the arc length and ranges from 0.50 to 1.50, with a nominal value of 1.00 for a 3/4" (19mm) electrode

FIGURE B.12

Trim .50 | Trim 1.00 | Trim 1.50 |

Arc Length Short | Arc Length Medium | Arc Length Long |