Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

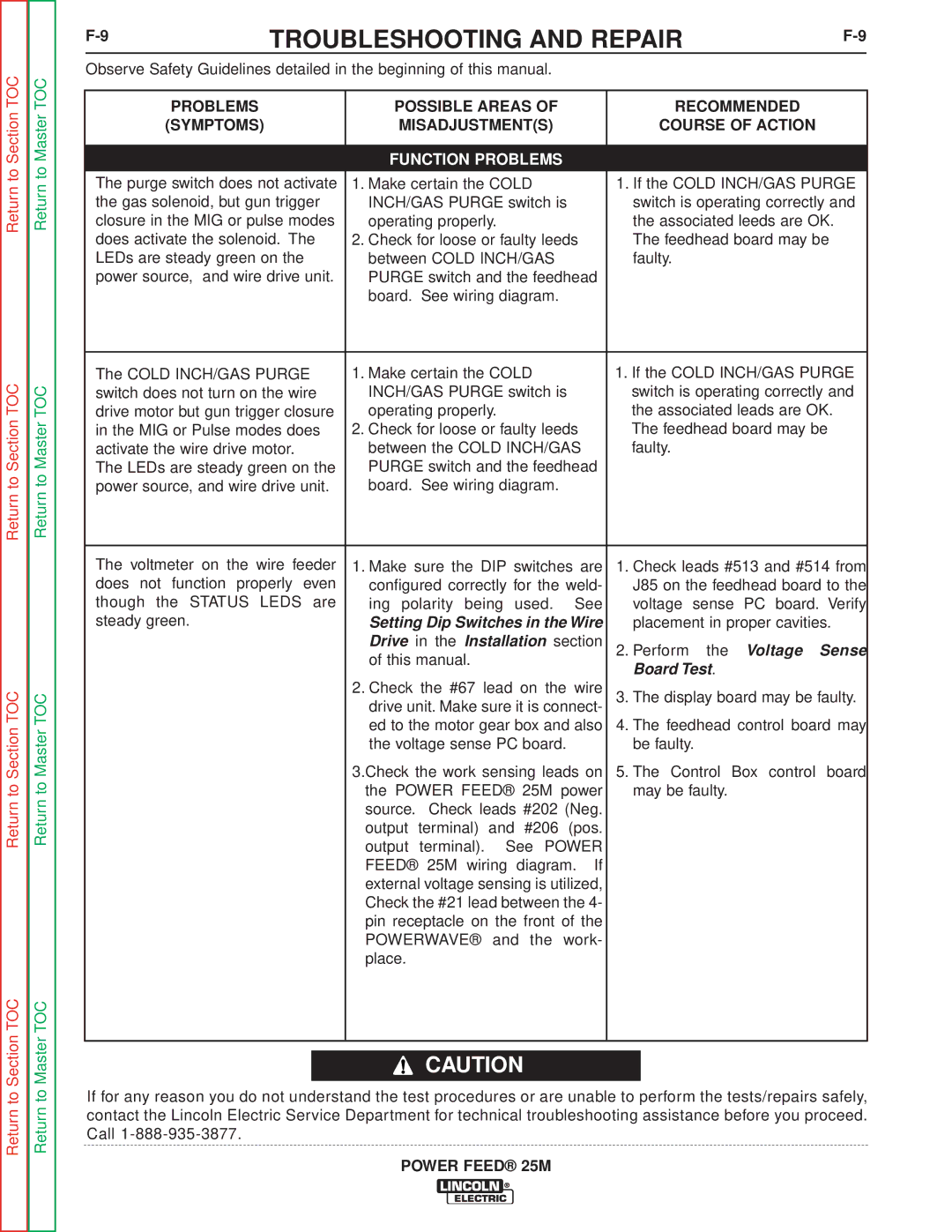

TROUBLESHOOTING AND REPAIR |

| ||||

Observe Safety Guidelines detailed in the beginning of this manual. |

|

|

| ||

|

|

|

| ||

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| ||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION |

| ||

|

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

The purge switch does not activate | 1. Make certain the COLD | 1. If the COLD INCH/GAS PURGE | |||

the gas solenoid, but gun trigger | INCH/GAS PURGE switch is | switch is operating correctly and | |||

closure in the MIG or pulse modes | operating properly. | the associated leeds are OK. | |||

does activate the solenoid. The | 2. Check for loose or faulty leeds | The feedhead board may be | |||

LEDs are steady green on the | between COLD INCH/GAS | faulty. |

|

| |

power source, | and wire drive unit. | PURGE switch and the feedhead |

|

|

|

|

| board. See wiring diagram. |

|

|

|

|

|

| |||

The COLD INCH/GAS PURGE | 1. Make certain the COLD | 1. If the COLD INCH/GAS PURGE | |||

switch does not turn on the wire | INCH/GAS PURGE switch is | switch is operating correctly and | |||

drive motor but gun trigger closure | operating properly. | the associated leads are OK. | |||

in the MIG or Pulse modes does | 2. Check for loose or faulty leeds | The feedhead board may be | |||

activate the wire drive motor. | between the COLD INCH/GAS | faulty. |

|

| |

The LEDs are steady green on the | PURGE switch and the feedhead |

|

|

| |

power source, and wire drive unit. | board. See wiring diagram. |

|

|

| |

|

|

| |||

The voltmeter on the wire feeder | 1. Make sure the DIP switches are | 1. Check leads #513 and #514 from | |||

does not function properly even | configured correctly for the weld- | J85 on the feedhead board to the | |||

though the STATUS LEDS are | ing polarity being used. See | voltage sense PC board. Verify | |||

steady green. |

| Setting Dip Switches in the Wire | placement in proper cavities. | ||

|

| Drive in the Installation section | 2. Perform the | Voltage | Sense |

|

| of this manual. | Board Test. |

|

|

|

|

|

|

| |

|

| 2. Check the #67 lead on the wire | 3. The display board may be faulty. | ||

|

| drive unit. Make sure it is connect- | |||

|

| ed to the motor gear box and also | 4. The feedhead control board may | ||

|

| the voltage sense PC board. | be faulty. |

|

|

|

| 3.Check the work sensing leads on | 5. The Control | Box control | board |

|

| the POWER FEED® 25M power | may be faulty. |

|

|

|

| source. Check leads #202 (Neg. |

|

|

|

|

| output terminal) and #206 (pos. |

|

|

|

|

| output terminal). See POWER |

|

|

|

|

| FEED® 25M wiring diagram. If |

|

|

|

|

| external voltage sensing is utilized, |

|

|

|

|

| Check the #21 lead between the 4- |

|

|

|

|

| pin receptacle on the front of the |

|

|

|

|

| POWERWAVE® and the work- |

|

|

|

|

| place. |

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call