Contents

Parts Catalog OCB429

Reference Manual

Indoor Unit

Safety Precaution

Always Observe for Safety

When charging directly from cylinder

Additional refrigerant charge

R22

PUZ-A18NHA2 PUZ-A18NHA2-BS PUY-A12/18NHA2 PUY-A12/18NHA2-BS

Features

PUZ-A42NHA2 PUZ-A42NHA2-BS PUY-A42NHA2 PUY-A42NHA2-BS

Specifications

PUZ-A18NHA2 PUZ-A24NHA2 PUZ-A30NHA2 PUZ-A36NHA2 PUZ-A42NHA2

PUY-A18NHA2-BS PUY-A24NHA2-BS

Compressor Technical Data

Data

Noise Criterion Curves

PUZ-A18NHA2-BS

Standard Operation Data

Heat pump

Cooling only

PKA-A12GA PKA-A18GA PKA-A24FA PKA-A30FA PKA-A36FA PLA-A42BA

Outdoor Unit

Unit mminch

Example of Notes

Service Space

662-5/8 Air outlet

Wiring Diagram

NET Adapter

PUZ-A24NHA2 PUZ-A24NHA2-BS PUY-A24NHA2 PUY-A24NHA2-BS

NET Adapter

WUse copper supply wires

TABU/V/W

Wiring Specifications

System Simultaneous twin system

Separate Indoor UNIT/OUTDOOR Unit Power Supplies

OFF

Indoor Outdoor Connecting Cable

NET Wiring Method

Refrigerant address NET address Control Remote Controller

NET address setting

Refrigerant address setting

Regulations in address settings

NET wiring

Refrigerant System Diagram

PUZ-A18NHA2 PUZ-A18NHA2-BS

PUZ-A42NHA2 PUZ-A42NHA2-BS

Way valve solenoid coil Heating on Cooling OFF

PUY-A12/18NHA2 PUY-A12/18NHA2-BS

PUY-A42NHA2 PUY-A42NHA2-BS

Refrigerant recovering pump down

Start and finish of test run

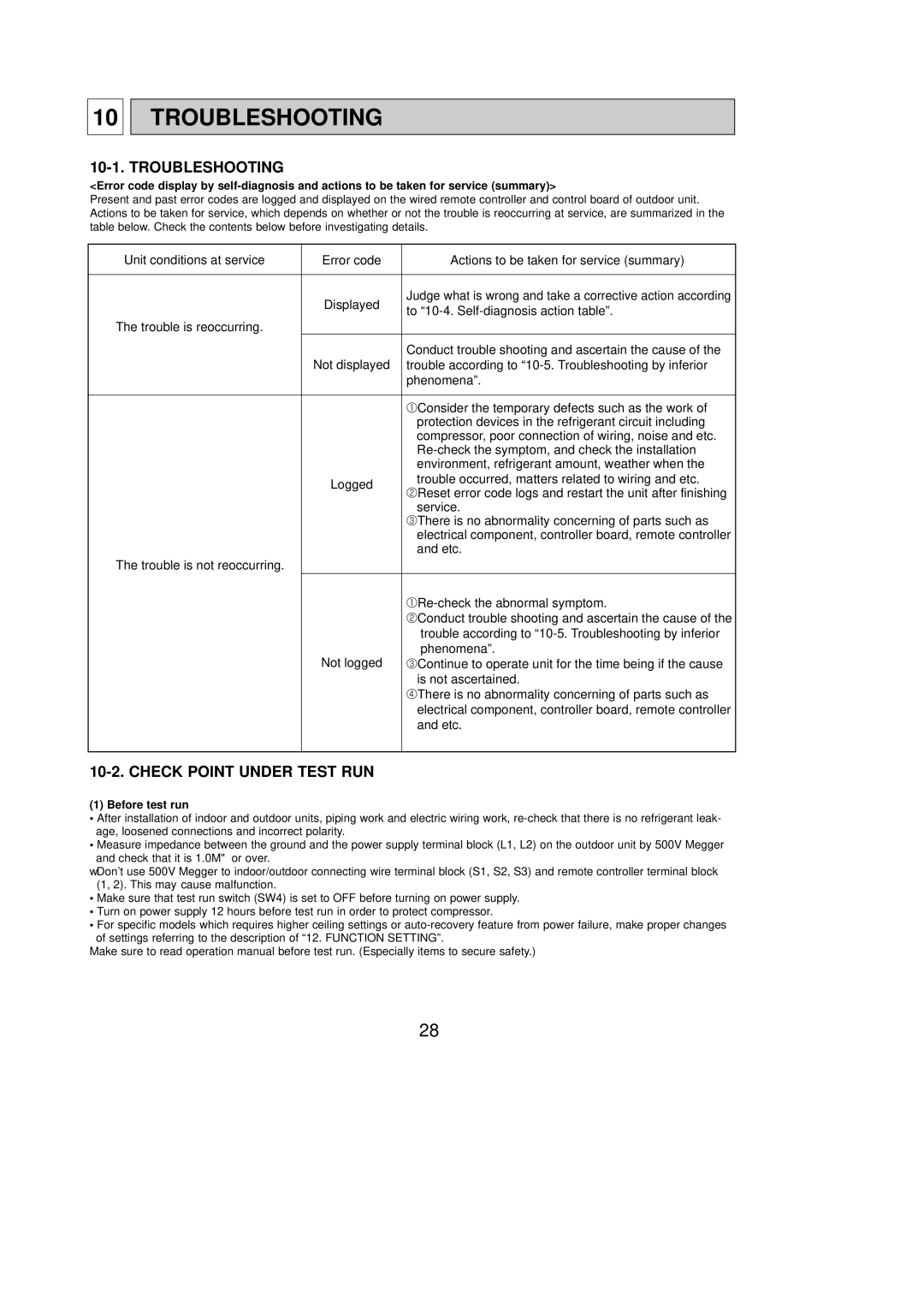

Troubleshooting

Troubleshooting

Check Point Under Test RUN

Before test run

Symptoms in test run mode Cause Remote Controller Display

Operating procedures

Contents of inferior phenomena

Test run for wireless remote controller

When a Problem Occurs During Operation

HOW to Proceed SELF-DIAGNOSIS

Self-Diagnosis During Maintenance or Service

Remote Controller Diagnosis

ON/OFF

Malfunction-diagnosis method by wireless remote controller

Malfunction-diagnosis method at maintenance service

Procedure

Case of trouble during operation

U9,UH

Error Code Abnormal point and detection method Case

63L connector open

SELF-DIAGNOSIS Action Table

Cndc

Error Code

Case Judgment and action 63H connector open

Connector open

Indoor/outdoor unit connector

Case Judgment and action High pressure High-pressure switch

High discharging temperature

Abnormalities detected while unit is operating

63H worked

Temperature thermistor TH4

Temperature of heatsink

Power module

Case Judgment and action Open/short circuit of discharge

Synchronous signal to main circuit

When compressor locked

Current sensor error

Case Judgment and action Outdoor fan motor

Remote controller transmission

ErrorE0/signal receiving errorE4

Remote controller control board

Case Judgment and action Low pressure 63L worked

Case Judgment and action Remote controller transmission

ErrorE3/signal receiving errorE5

Error Signal receiving error

Non defined error code

NET communication error

Case Judgment and action Pipe temperature

Hardware error of transmission

Case Judgment and action Address duplicate definition

To the next

From the previous

Fresh Master

Master

Lossnay

VCTF, VCTFK, CVV CVS, VVR, VVF, VCT

Troubleshooting by Inferior Phenomena

Phenomena Factor Countermeasure

Melans

Please Wait

YES

Outdoor power circuit board

Power supply To the outdoor unit Check the breaker

Outdoor connecting wire

Miswiring, breaking

Indoor/outdoor connecting wire Blinking

Defective indoor Replace the indoor Power board

Not lighting

Breaking or poor Fix the breaking or poor

Check if there is breaking

Before repair Frequent calling from customers

Action Table

Phone Calls From Customers How to Respond

Sometimes This is the sound which is heard when the flow

Refrigerant in the air conditioner is switched

This is not a malfunction

With Airflow Direction…

With Blower…

There might be a case that

Page

HOW to Check the Parts

Wiring contact check

Power supply check Remove the connector CNF1

Fuse check

END

HOW to Check the Components

Thermistor feature chart Low temperature thermistors

Medium temperature thermistor

High temperature thermistor

Operation summary of the linear expansion valve

Output pulse signal and the valve operation

Linear expansion valve operation

Linear expansion valve A24, 30, 36

How to detach the coil

How to attach the coil

Be sure to attach the stopper

Emergency operation procedure

Emergency Operation

Releasing emergency operation

SW4

Operation data during emergency operation

Test Point Diagram

LI, NI

CNAC1, CNAC2

CN5

LO, no

PUZ-A24NHA2 PUZ-A24NHA2-BS PUY-A24NHA2 PUY-A24NHA2-BS

RS1

LD1-LD2

DIP-PFC

DIP-IPM

CN3 CN4 CN5

Cnaf

CN3

TABP2/SC-P2

Actm

Lower side

Upper side

L1, L2

Function of SWITCHES, Connectors and Jumpers

Function of switches

Function Action by the switch operation Effective timing

OFF

2Function of connector

SW9

50%

Special function

75%

Display function of inspection for outdoor unit

Blinking Abnormality of outdoor fan Motor rotational speed

1Check the outdoor fan motor 1Check if stop valves are open

Operation indicator

Digital indicator LED1 working details

Example When 42500 times 425 100 times Secs 5secs

~9999 When it is 100 hours or more, hundreds digit, tens

Example When 2450 hours 245 10 hours

Lighting Cancellation of postponement

SW2 setting Display detail Explanation for display Unit

Outdoor unit setting information

Single phase 2 3 phase

Unit

Cooling only

DegF

Fan step on error occurring ~10 Step

Example When 130 pulse

Discharge superheat on error occurring ~327 0~182degC SHd

Secs Sub cool on error occurring. SC ~234 0~130degC

Example When 415 minutes Minute Secs

U9 Error status during the Error

Rise of discharge temperature

LED

Easy Maintenance Function

Maintenance Mode Operation Method

Switching to maintenance mode

Fixed Hz operation

Data measurement

To check the data for each item, repeat steps 5 to

Guide for Operation Condition

Function Setting

Unit Function Setting by the Remote Controller

Data of the sensor Ta=C On main remote Controller

Average data Initial Ta=A+B/2 Sensor on all

Setting No Settings

Mode No.11

PLA-BA PCA-GA

Selecting functions using the wired remote controller

For modes 15 and higher

Specified indoor unit

Press E FAN operation

Operating Procedure

Flow of function selection procedure

Operating instructions

Function Selection of Remote Controller

Mode Selection

Function selection flowchart

Mode Vane

FAN

Button for 3 seconds to switch to Maintenance monitor

Check button for 3 seconds to return to maintenance mode

Turn on the Monitoring the operation data

Press

Request Code List

Outdoor unit-Control state

Code Description

100

For indoor fan pulsation control

Detail Contents in Request Code

101

Error content U9 Request code

102

Fan control state Request code

Actuator output state Request code

Outdoor unit --Capacity setting display Request code

Outdoor unit Setting information Request code

103

Contact demand capacity Request code

104

Indoor unit Model setting information Request code

Indoor unit Capacity setting information Request code

105

Data display See the table on the right

Disassembly Procedure

PUZ-A18NHA2 PUZ-A18NHA2-BS Operating Procedure Photos

106

Photo

Removing the thermistor Outdoor 2-phase pipe TH6

107

Removing the electrical parts box

Thermistor Outdoor pipe TH3

Operating Procedure Photos

108

Removing the 4-way valve

109

Removing linear expansion valve

Separator Recover refrigerant

110

Removing the compressor MC

Removing the accumulator

Operating Procedure Photos & Illustration

Removing the service panel and top panel

111

Removing the fan motor MF1

Removing the thermistor Outdoor pipe TH3

112

Thermistor Discharge TH4

113

Removing the 4-way valve coil

Removing the linear expansion valve coil

Removing the bypass valve coil

Removing the bypass valve

114

Removing the reactor ACLA24

Removing the reactor DCL A30

115

Remove 2 receiver leg fixing screws 4

116

Removing the fan motor MF1, MF2

117

Remove the service panel. See figure Outdoor pipe

Remove the top panel. See figure Controller

118

Are not oxidized

Linear expansion

Coil Valve coil

Low pressure switch 63L

119

Removing the reactor DCL and capacitor CE

DCL

Remove 2 back cover panel fixing screws 5 10