Error Code | Abnormal point and detection method | Case | | | | | | | | Judgment and action | | | | |

| Pipe temperature | 1 Slight temperature difference | 1~4 Check pipe <liquid or condenser / | | |

| <Cooling mode> | between indoor room | | | | | | evaporator> temperature with room | | |

| Detected as abnormal when the pipe tem- | temperature and pipe <liquid | | | | | | temperature display on remote | | | | |

| perature is not in the cooling range 3 min- | or condenser / evaporator> | | | | | | controller and outdoor controller circuit |

| utes after compressor start and 6 minutes | temperature thermistor | | | | | | board. | | | | | | | | | | | | |

| after the liquid or condenser/evaporator pipe | • Shortage of refrigerant | | | | | | Pipe <liquid or condenser / evaporator> |

| is out of cooling range. | • Disconnected holder of pipe | | | | | | temperature display is indicated by | | |

| Note 1) It takes at least 9 min. to detect. | <liquid or condenser / | | | | | | setting SW2 of outdoor controller circuit |

| Note 2) Abnormality P8 is not detected in | evaporator> thermistor | | | | | | board as follows. | | | | | | | | | ) | |

| drying mode. | • Defective refrigerant circuit | | | Conduct temperature check with outdoor | |

| Cooling range : Indoor pipe temperature | 2 Converse connection of | | | |

| | | controller circuit board after connecting | |

| | | | | |

| (TH2 or TH5) – intake temperature | extension pipe (on plural units | (‘A-Control Service Tool(PAC-SK52ST)’. | |

| (TH1) [ -3 deg [-5.4˚F] | connection) | | | | | | | | | | | | | | | | | | | | | |

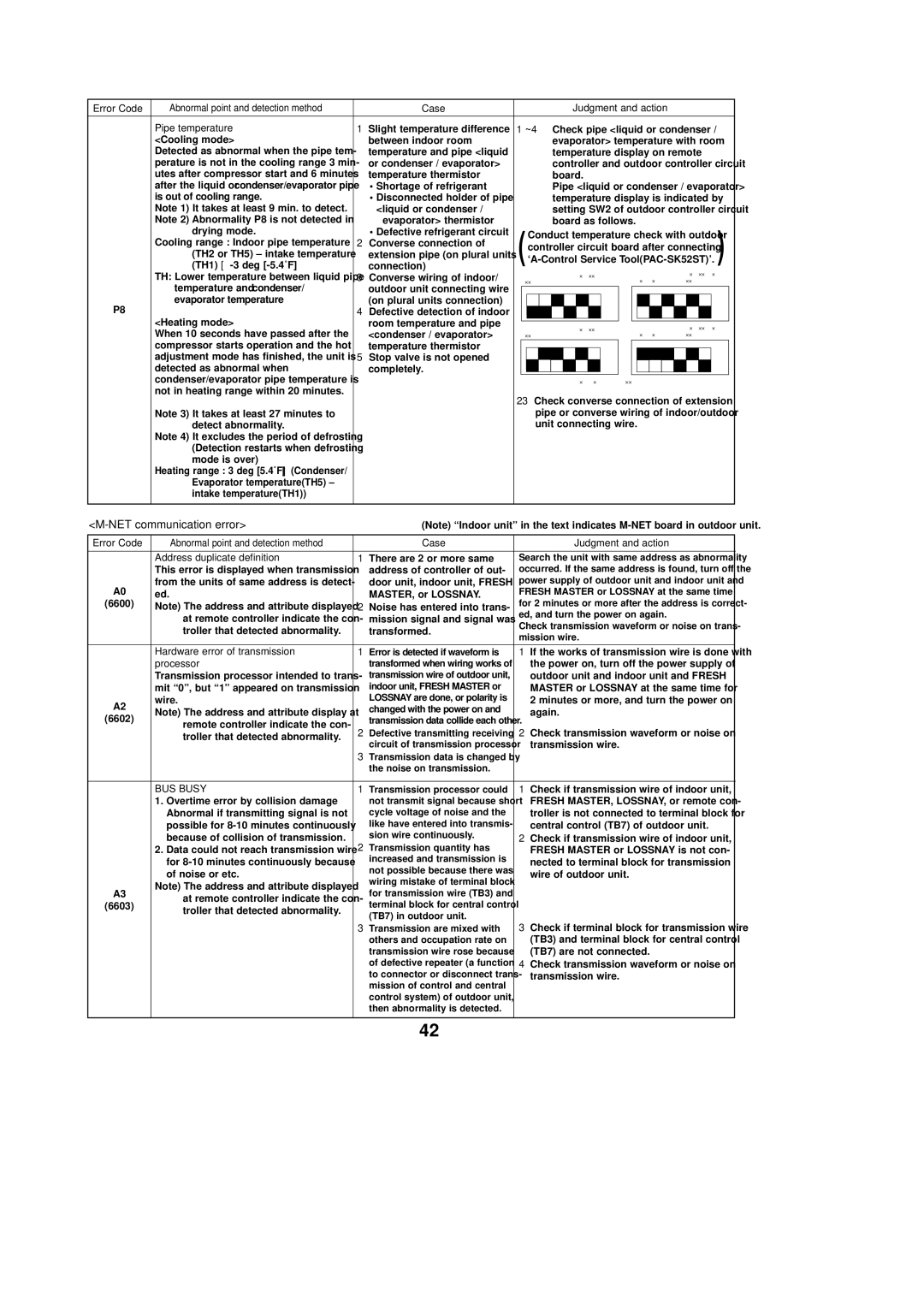

| TH: Lower temperature between liquid pipe | 3 Converse wiring of indoor/ | | Temperature display of indoor liquid pipe | Temperature display of indoor condenser/ |

| | | |

| temperature and condenser/ | outdoor unit connecting wire | | Indoor 1 | | | | | | | evaporator pipe | Indoor 1 | | | | |

| | 1 | 2 | 3 | 4 | 5 | 6 | | 1 | 2 | 3 | 4 | | 5 | 6 | | |

P8 | evaporator temperature | (on plural units connection) | | | | | | | | | | ON | | | | | | | | | | ON | |

| 4 Defective detection of indoor | | | | | | | | | | OFF | | | | | | | | | | OFF | |

| <Heating mode> | room temperature and pipe | | | | | | | | | | | | | | | | | | | | | |

| | Temperature display of indoor liquid pipe | Temperature display of indoor condenser/ |

| When 10 seconds have passed after the | <condenser / evaporator> | |

| | Indoor 2 | | | | | | | evaporator pipe | Indoor 2 | | | | |

| compressor starts operation and the hot | temperature thermistor | | 1 | 2 | 3 | 4 | 5 | 6 | | 1 | 2 | 3 | 4 | | 5 | 6 | | |

| adjustment mode has finished, the unit is | 5 Stop valve is not opened | | | | | | | | | | ON | | | | | | | | | | ON | |

| | | | | | | | | | | | | | | | | | | | | |

| detected as abnormal when | completely. | | | | | | | | | | OFF | | | | | | | | | | OFF | |

| | | | | | | | | | | | | | | | | | | | | |

| condenser/evaporator pipe temperature is | | | | | | | | | | A-Control Service Tool SW2 setting | | | | |

| not in heating range within 20 minutes. | | 23Check converse connection of extension |

| | |

| Note 3) It takes at least 27 minutes to | | | | | pipe or converse wiring of indoor/outdoor |

| detect abnormality. | | | | | unit connecting wire. | | | | | | | | | | |

| Note 4) It excludes the period of defrosting | | | | | | | | | | | | | | | | | | | | | | |

| (Detection restarts when defrosting | | | | | | | | | | | | | | | | | | | | | | |

| mode is over) | | | | | | | | | | | | | | | | | | | | | | |

| Heating range : 3 deg [5.4˚F] [ (Condenser/ | | | | | | | | | | | | | | | | | | | | | | |

| Evaporator temperature(TH5) – | | | | | | | | | | | | | | | | | | | | | | |

| intake temperature(TH1)) | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

<M-NET communication error> | (Note) “Indoor unit” in the text indicates M-NET board in outdoor unit. |

| | | | | | | | | | | | | | | | | | | | | | | |

Error Code | Abnormal point and detection method | Case | | | | | | | | Judgment and action | | | | |

| | | | | | | | | | | | | | | | | | | |

| Address duplicate definition | 1 There are 2 or more same | Search the unit with same address as abnormality |

| This error is displayed when transmission | address of controller of out- | occurred. If the same address is found, turn off the |

A0 | from the units of same address is detect- | door unit, indoor unit, FRESH | power supply of outdoor unit and indoor unit and |

ed. | MASTER, or LOSSNAY. | FRESH MASTER or LOSSNAY at the same time |

(6600) | Note) The address and attribute displayed | 2 Noise has entered into trans- | for 2 minutes or more after the address is correct- |

| at remote controller indicate the con- | mission signal and signal was | ed, and turn the power on again. | | | | | | | |

| Check transmission waveform or noise on trans- |

| troller that detected abnormality. | transformed. |

| mission wire. | | | | | | | | | | | | |

| | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

| Hardware error of transmission | 1 Error is detected if waveform is | 1 If the works of transmission wire is done with |

| processor | transformed when wiring works of | | | the power on, turn off the power supply of |

| Transmission processor intended to trans- | transmission wire of outdoor unit, | | | outdoor unit and indoor unit and FRESH | | |

| mit “0”, but “1” appeared on transmission | indoor unit, FRESH MASTER or | | | MASTER or LOSSNAY at the same time for |

A2 | wire. | LOSSNAY are done, or polarity is | | | 2 minutes or more, and turn the power on |

Note) The address and attribute display at | changed with the power on and | | | again. | | | | | | | | | | | | | | | |

(6602) | | | | | | | | | | | | | | | | | |

remote controller indicate the con- | transmission data collide each other. | | | | | | | | | | | | | | | | | | | | | |

| 2 Defective transmitting receiving | 2 Check transmission waveform or noise on |

| troller that detected abnormality. |

| circuit of transmission processor | | | transmission wire. | | | | | | | | | | |

| | | | | | | | | | | | | |

| | 3 Transmission data is changed by | | | | | | | | | | | | | | | | | | | | | |

| | the noise on transmission. | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | |

| BUS BUSY | 1 Transmission processor could | 1 Check if transmission wire of indoor unit, |

| 1. Overtime error by collision damage | not transmit signal because short | | | FRESH MASTER, LOSSNAY, or remote con- |

| Abnormal if transmitting signal is not | cycle voltage of noise and the | | | troller is not connected to terminal block for |

| possible for 8-10 minutes continuously | like have entered into transmis- | | | central control (TB7) of outdoor unit. | | | |

| because of collision of transmission. | sion wire continuously. | 2 Check if transmission wire of indoor unit, |

| 2. Data could not reach transmission wire | 2 Transmission quantity has | | | FRESH MASTER or LOSSNAY is not con- |

| for 8-10 minutes continuously because | increased and transmission is | | | nected to terminal block for transmission |

| of noise or etc. | not possible because there was | | | wire of outdoor unit. | | | | | | | | | | |

| wiring mistake of terminal block | | | | | | | | | | | | |

| Note) The address and attribute displayed | | | | | | | | | | | | | | | | | | | | | |

A3 | for transmission wire (TB3) and | | | | | | | | | | | | | | | | | | | | | |

at remote controller indicate the con- | | | | | | | | | | | | | | | | | | | | | |

(6603) | terminal block for central control | | | | | | | | | | | | | | | | | | | | | |

troller that detected abnormality. | | | | | | | | | | | | | | | | | | | | | |

| (TB7) in outdoor unit. | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | |

| | 3 Transmission are mixed with | 3 Check if terminal block for transmission wire |

| | others and occupation rate on | | | (TB3) and terminal block for central control |

| | transmission wire rose because | | | (TB7) are not connected. | | | | | | | | |

| | of defective repeater (a function | 4 Check transmission waveform or noise on |

| | to connector or disconnect trans- | | | transmission wire. | | | | | | | | | | |

| | mission of control and central | | | | | | | | | | | | | | | | | | | | | |

| | control system) of outdoor unit, | | | | | | | | | | | | | | | | | | | | | |

| | then abnormality is detected. | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | |