Adept SmartController

User’s Guide

Page

00356-00100, Rev. E May

Page

Table of Contents

Table of Contents

SmartController Operation

SmartController Maintenance

SDIO Module

Using the Manual Control Pendant MCP 125

Index

List of Figures

Figure A-1

List of Figures

List of Tables

List of Tables

Introduction

Product Description

Adept SmartController CS

Adept SmartController CX

How Can I Get Help?

Related Manuals

Adept Document Library

Introduction

Safety

Reading and Training for Users and Operators

Computer Controlled Robots and Motion Devices

System Safeguards

Safety Features on the Front Panel

Safety

Program Security

Manually Controlled Robots and Motion Devices

Other Computer-Controlled Devices

Standards Compliance

Inappropriate Uses of the Adept SmartController

CAT-3 Version of SmartController

Identification

Functionality Changes

Stop Circuit

Operational Change in SmartModule Systems

SmartController Installation

Controller Installation

Before Unpacking

Upon Unpacking

SmartController Installation

Repacking for Relocation

Space Around the Chassis

Mounting the SmartController

Controller Installation

Rack Mounting the SmartController

Panel Mounting the SmartController

Panel Mounting the SmartController

Table Mounting the SmartController

Table Mounting the SmartController

Stacking Components

CompactFlash Memory Card

Installing CompactFlash

CompactFlash Memory Card Compartment

Connecting Power

24VDC Power Specifications

Grounding

24VDC Power Cabling

Daisy-Chaining Power

Installing 24VDC Connectors

Grounding Point

Ieee 1394 Cable Specifications

V Connectors

System Cable Installation

PDU2

System Cable Installation

Page

SmartController CS Connectors and Indicators

SmartController Operation

Top Three Status LEDs

Green Indicates Red Indicates

LED Display Error # Description

SW1 DIP switches

DeviceNet connector

Bottom Three Status LEDs

Ethernet Eth 10/100 connector

RS-232 and RS-422/485 connectors

Xdio connector

Xusr connector

SmartController CX Connectors and Indicators

System 5V Power On LED

Manual/Automatic Mode Switch

High Power On/Off Switch & Lamp

Front Panel

Configuring the Controller

Factory Default Settings

DIP-Switch Settings

Emergency Stop Switch

Configuring the Controller

Row # Interpretation

AdeptWindows PC Graphical User Interface

Ascii Terminal

SmartController Serial I/O Connectors

RS-232 Connectors

Auto Boot

Pin Signal Type

Controller Connector + Designation

RS-422/485 Connector

SmartController Serial I/O Connectors

Installing the User Interface

Graphical Interface Using AdeptWindows

Text Interface Using a PC with HyperTerminal Software

Installing the User Interface

Installation Procedure

Start = Programs = Accessories = HyperTerminal

Text Interface Using a Terminal

Recommended Terminal for Text-Based Systems

Connecting Equipment to the System

Pin Description Comments Shorted if Pairs Not Used

Pin Pairs

Description Comments

Pin Xmcp Pin MCP Description Pin D-Sub Pin CPC

CAT-3 E-Stop Circuit on Xusr and XFP Connectors

Stop, High Power On/Off and MANUAL/AUTO Controls

Adept Front Panel Schematic

Emergency Stop Circuits

Line E-Stop Input

Muted Safety Gate E-Stop Circuitry

User E-Stop Indication Remote Sensing of E-Stop

Remote Manual Mode

User High Power On Indication

Remote Front Panel Usage

Remote High Power On/Off Control

High Power On/Off Lamp

Connecting Customer-Supplied Digital I/O Equipment

Remote MCP Usage

Input Signals

Xdio Connector

Connecting Customer-Supplied Digital I/O Equipment

React Input Signals 1001 to

Fast Input Signals 1001 to

Output Signals

11. DIO Output Specifications Xdio connector

Digital Output Wiring for Xdio Connector

Pin Signal

Digital I/O Connector Ordering Details Third-Party Sources

Screw-Terminal Field-Wiring Adapter Blocks

Belt Encoder Interface on SmartController CX

Channel Signal Pin

Belt Encoder Interface on SmartController CX

Belt Encoder Typical Input Circuit

SAVI Board Features

AdeptVision sAVI Option

Introduction

SAVI Board System Requirements and Restrictions

Camera Compatibility

Pixel Format

AdeptVision sAVI Inspection System Limitations

Guidelines for Cameras

Standard Resolution Cameras

High Resolution Cameras

Cameras Supported

Camera Compatibility

Camera Cables

Two-Camera Breakout Cable for RS-170 Cameras

Camera Cables

Four-Camera Breakout Cable for RS-170 Cameras

Meter Camera Extension Cables

Installing Camera Cables

Connecting the Cables to the RS-170 Standard Camera

Installing Camera Cables

Camera Cable Installation Drawing RS-170

Camera Cable Pin and Signal Information

Camera Cable Pin and Signal Information

Pin Function

Pin Function

Pin Locations for Camera Cable Connector 12-Pin Hirose Male

From Pin Function

From Pin Function

Str/Pwr User +12 V to cameras User power return

Pin

Pin

SAVI Board Specifications

SAVI Board Specifications

Page

SmartController Maintenance

Changing the Lamp in the High Power Indicator

SmartController Maintenance

Lamp Body Contact Alignment

Technical Specifications

SmartController Dimensions

SDIO Dimensions

Technical Specifications

Adept Front Panel Dimensions

Adept Front Panel Dimensions

Adept Front Panel Back View

Adept MCP Dimensions

Adept MCP Dimensions

MCP Cradle Dimensions

SDIO Module a

Mounting the sDIO

Rack Mounting the sDIO

Appendix a sDIO Module

Panel Mounting the sDIO

Mounting the sDIO

Stack Mounting

Installing the sDIO

Table Mounting the sDIO

Configuring a Single sDIO

Default sDIO I/O Configuration

Configuring a Single sDIO

Input Signal Block Byte Output Signal Numbers

Configure 1394 DIO

Modifying the Default sDIO Configuration

Assigning sDIO Signal Blocks

Assigning I/O Signal Numbers

+ System Configuration Data Then, press Enter to continue

Enter new value

Do you want to save these changes?

Edit system configuration Then, press Enter to continue

100 Adept SmartController User’s Guide, Rev. E

SDIO Signal Mapping Example

Adept SmartController User’s Guide, Rev. E 101

Using Multiple sDIO Modules

102 Adept SmartController User’s Guide, Rev. E

SDIO Module Connectors and Indicators

Configuring a System with an sDIO and a RIO

SDIO Module Connectors and Indicators

Status LEDs

104 Adept SmartController User’s Guide, Rev. E

SDIO Digital I/O Signals

SDIO Inputs

SDIO Digital I/O Signals

Adept SmartController User’s Guide, Rev. E 105

Testing sDIO Outputs

SDIO Outputs

SDIO LEDs

106 Adept SmartController User’s Guide, Rev. E

Adept SmartController User’s Guide, Rev. E 107

SDIO Output Power Supply Current Selection

Illumination Upper LED Link Lower LED OK SF

Parameter Value

108 Adept SmartController User’s Guide, Rev. E

Smart-DIO

Adept SmartController User’s Guide, Rev. E 109

110 Adept SmartController User’s Guide, Rev. E

Optional DIO Cables

Labeling Cables

Adept SmartController User’s Guide, Rev. E 111

Input and Output Cable Wiring Information

Pin Signal Wire Number Group Color Locations

112 Adept SmartController User’s Guide, Rev. E

Pin Group Signal name Wire Number Color Pin Locations

Adept SmartController User’s Guide, Rev. E 113

114 Adept SmartController User’s Guide, Rev. E

DeviceNet Specifications

Volume

Adept DeviceNet B

Adept SmartController User’s Guide, Rev. E 115

Pin Signal Name

Limitations of the Adept DeviceNet Scanner

Adept Supplied DeviceNet Hardware

Appendix B Adept DeviceNet

Adept SmartController User’s Guide, Rev. E 117

DeviceNet Physical Layer and Media

DeviceNet Physical Layer and Media

118 Adept SmartController User’s Guide, Rev. E

Data Rates Kbps

Adept SmartController User’s Guide, Rev. E 119

Figure B-2. DeviceNet Thick Cable

120 Adept SmartController User’s Guide, Rev. E

DeviceNet Connectors

Connector Description

Termination of the DeviceNet Network

Adept SmartController User’s Guide, Rev. E 121

122 Adept SmartController User’s Guide, Rev. E

Power Supply and the DeviceNet Bus

Power Capabilities of a DeviceNet Cable System

Length of Dropline Maximum Current

Adept SmartController User’s Guide, Rev. E 123

Figure B-6. DeviceNet Connector Pinouts

124 Adept SmartController User’s Guide, Rev. E

Using the Manual C Control Pendant MCP

MCP Enable Switch Function on CAT-3 SmartController

Manual Control Pendant Basics

Adept SmartController User’s Guide, Rev. E 125

126 Adept SmartController User’s Guide, Rev. E

Appendix C Using the Manual Control Pendant MCP

Position Enable Switch

Adept SmartController User’s Guide, Rev. E 127

Manual Control Pendant Basics

MCP-4 Compatibility

128 Adept SmartController User’s Guide, Rev. E

CMD

Connecting the MCP

Adept SmartController User’s Guide, Rev. E 129

MCP Layout

Soft Buttons

Function Buttons

130 Adept SmartController User’s Guide, Rev. E

Mode Control and Joint/Axis Control Buttons

Emergency Stop From the MCP

Data Entry Buttons

Speed Bars and Slow Button

Re-Enabling Power After Enable Switch Released

Original SmartController

CAT-3 SmartController

132 Adept SmartController User’s Guide, Rev. E

Background Mode

MCP Predefined Functions

Introduction

Predefined Function Buttons

Edit Function

134 Adept SmartController User’s Guide, Rev. E

Display Function

Adept SmartController User’s Guide, Rev. E 135

136 Adept SmartController User’s Guide, Rev. E

Adept SmartController User’s Guide, Rev. E 137

Clear Error Function

CMD Function

Figure C-10. Command CMD Function Button

138 Adept SmartController User’s Guide, Rev. E

Prog Set Function

Adept SmartController User’s Guide, Rev. E 139

140 Adept SmartController User’s Guide, Rev. E

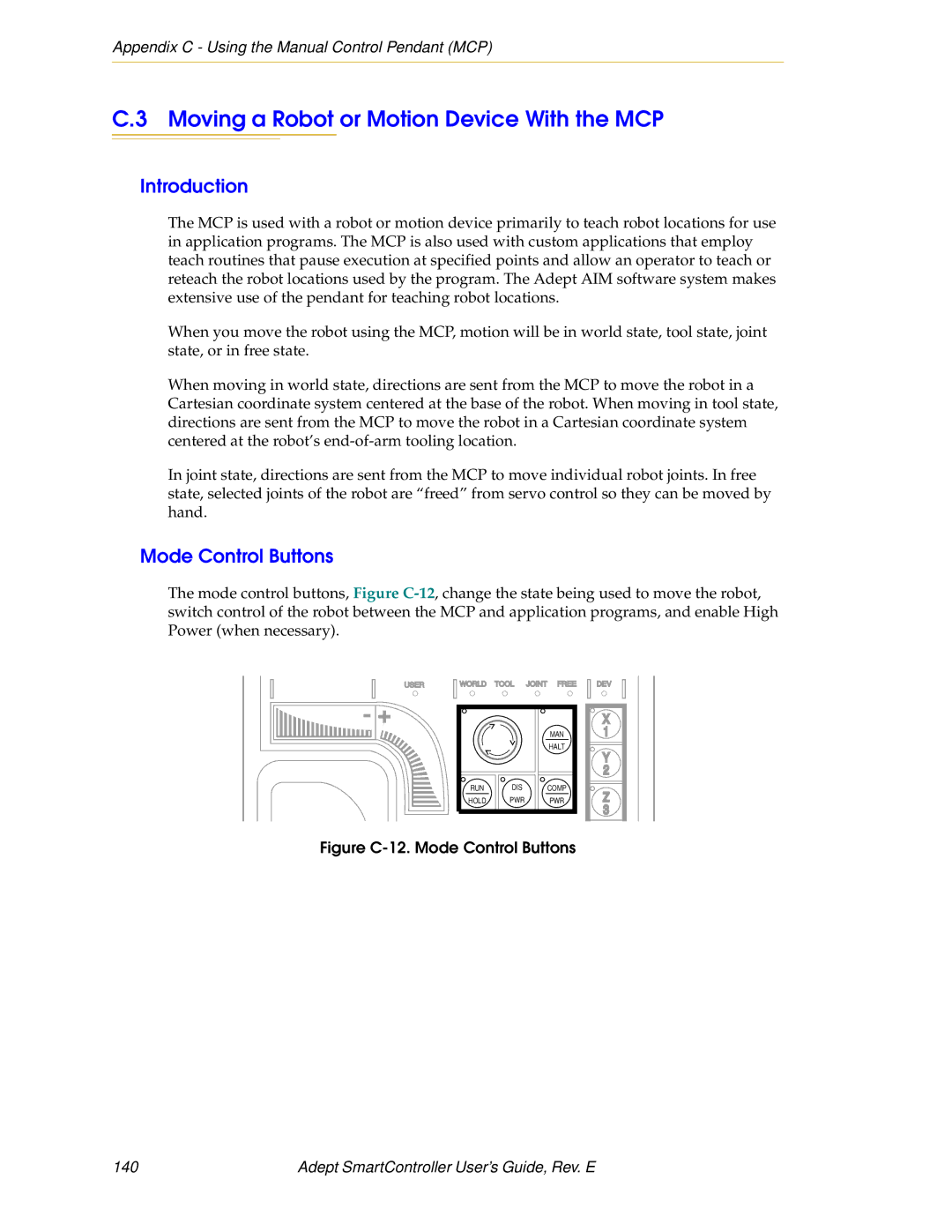

Mode Control Buttons

Moving a Robot or Motion Device With the MCP

Emergency Stop Switch

Moving a Robot or Motion Device With the MCP

COMP/PWR Button

MAN/HALT Button

142 Adept SmartController User’s Guide, Rev. E

Joint/Axis Control Buttons

Speed Bars

Comp Mode

Slow Button

Robot States

World State

Tool State

144 Adept SmartController User’s Guide, Rev. E

+RZ

Adept SmartController User’s Guide, Rev. E 145

Figure C-16. Tool State Six-Axis Robot

146 Adept SmartController User’s Guide, Rev. E

Joint State

Adept SmartController User’s Guide, Rev. E 147

Free State

148 Adept SmartController User’s Guide, Rev. E

Controlling More Than One Robot

Adept SmartController User’s Guide, Rev. E 149

DEV LED state Robot selected by pendant

Robots With Fewer Than Six Joints

Robots With More Than Six Joints

Joint/Axis LED state Joint range

Index

Adept SmartController User’s Guide, Rev. E 151

Index

152 Adept SmartController User’s Guide, Rev. E

143

Adept SmartController User’s Guide, Rev. E 153

154 Adept SmartController User’s Guide, Rev. E

Page

Triad Drive