PLACE THE BOILER

16.To properly assemble LC/LCE sections in the field, the following steps must be followed to ensure that no damage occurs to the tie rod lugs. A

a.Use a spirit level as shown in Figure 2.4 to check the alignment of the sections as the nuts are drawn up. Keep the sections plumb.

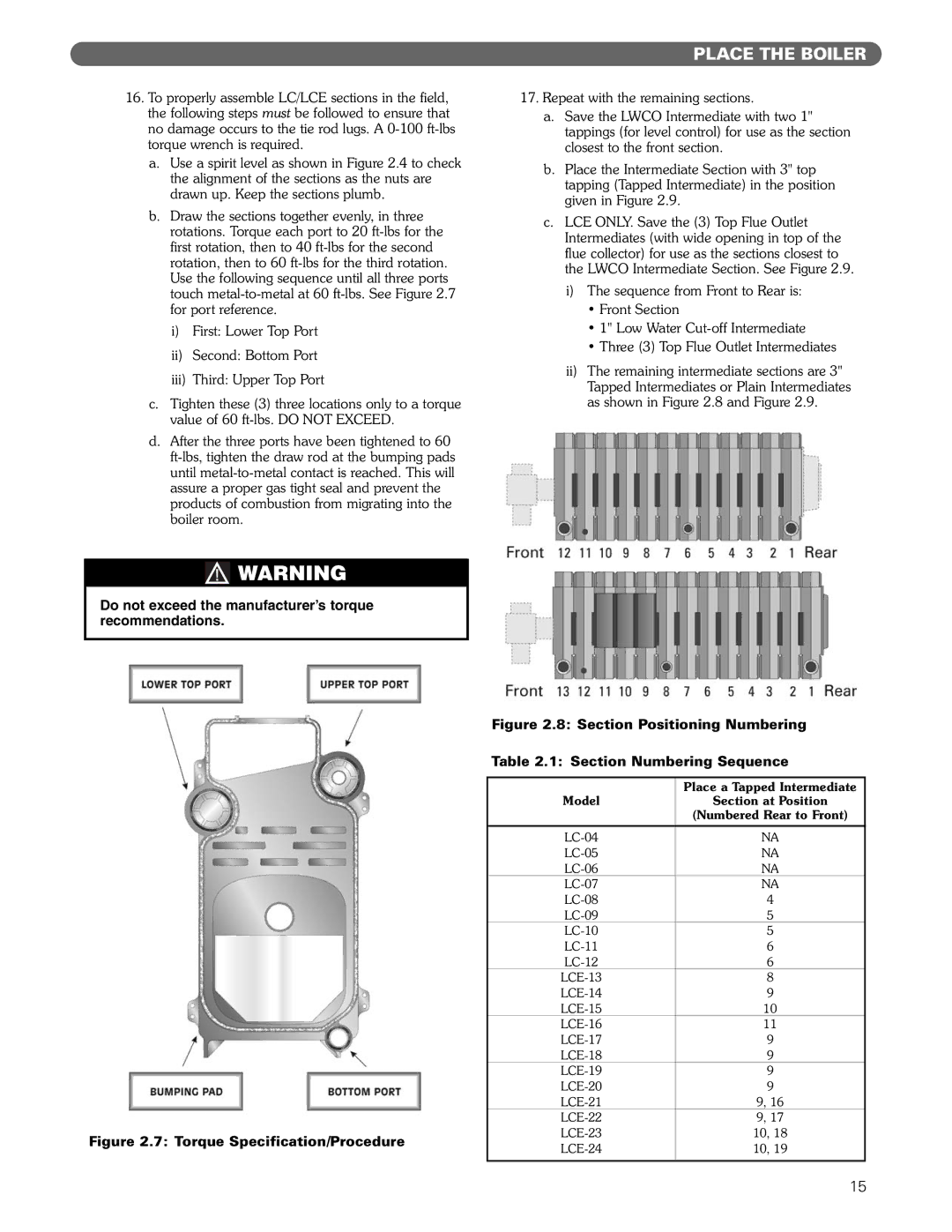

b.Draw the sections together evenly, in three rotations. Torque each port to 20

i)First: Lower Top Port

ii)Second: Bottom Port

iii)Third: Upper Top Port

c.Tighten these (3) three locations only to a torque value of 60

d.After the three ports have been tightened to 60

17.Repeat with the remaining sections.

a.Save the LWCO Intermediate with two 1" tappings (for level control) for use as the section closest to the front section.

b.Place the Intermediate Section with 3" top tapping (Tapped Intermediate) in the position given in Figure 2.9.

c.LCE ONLY. Save the (3) Top Flue Outlet Intermediates (with wide opening in top of the flue collector) for use as the sections closest to the LWCO Intermediate Section. See Figure 2.9.

i)The sequence from Front to Rear is:

•Front Section

•1" Low Water

•Three (3) Top Flue Outlet Intermediates

ii)The remaining intermediate sections are 3" Tapped Intermediates or Plain Intermediates as shown in Figure 2.8 and Figure 2.9.

![]() WARNING

WARNING

Do not exceed the manufacturer’s torque recommendations.

Figure 2.7: Torque Specification/Procedure

Figure 2.8: Section Positioning Numbering

Table 2.1: Section Numbering Sequence

Model | Place a Tapped Intermediate |

Section at Position | |

| (Numbered Rear to Front) |

|

|

NA | |

NA | |

NA | |

NA | |

4 | |

5 | |

5 | |

6 | |

6 | |

8 | |

9 | |

10 | |

11 | |

9 | |

9 | |

9 | |

9 | |

9, 16 | |

9, 17 | |

10, 18 | |

10, 19 | |

|

|

15