PLACE THE BOILER

![]() WARNING

WARNING

The sections are heavy and must be supported securely.

10. Lift up the Rear Section and move into position on the steel channels on the boiler foundation.

11. Screw a 3" pipe at least 30 inches long into the lower 3" tapping on the back of the Rear Section as shown in Figure 2.4. Place a block under the pipe as shown in the figure and use as a brace during assembly.

12. Place a Plain Intermediate Section on the floor and prepare as above.

13. Carefully place the Intermediate Section against the Rear Section and visually line up the flow ports as close as possible.

14. Insert a tie rod with one nut and washer applied into each of the four tie rod lugs. See Figures 2.5 and 2.6.

15. Place the nut and washer on the other end of the tie rod and draw finger tight.

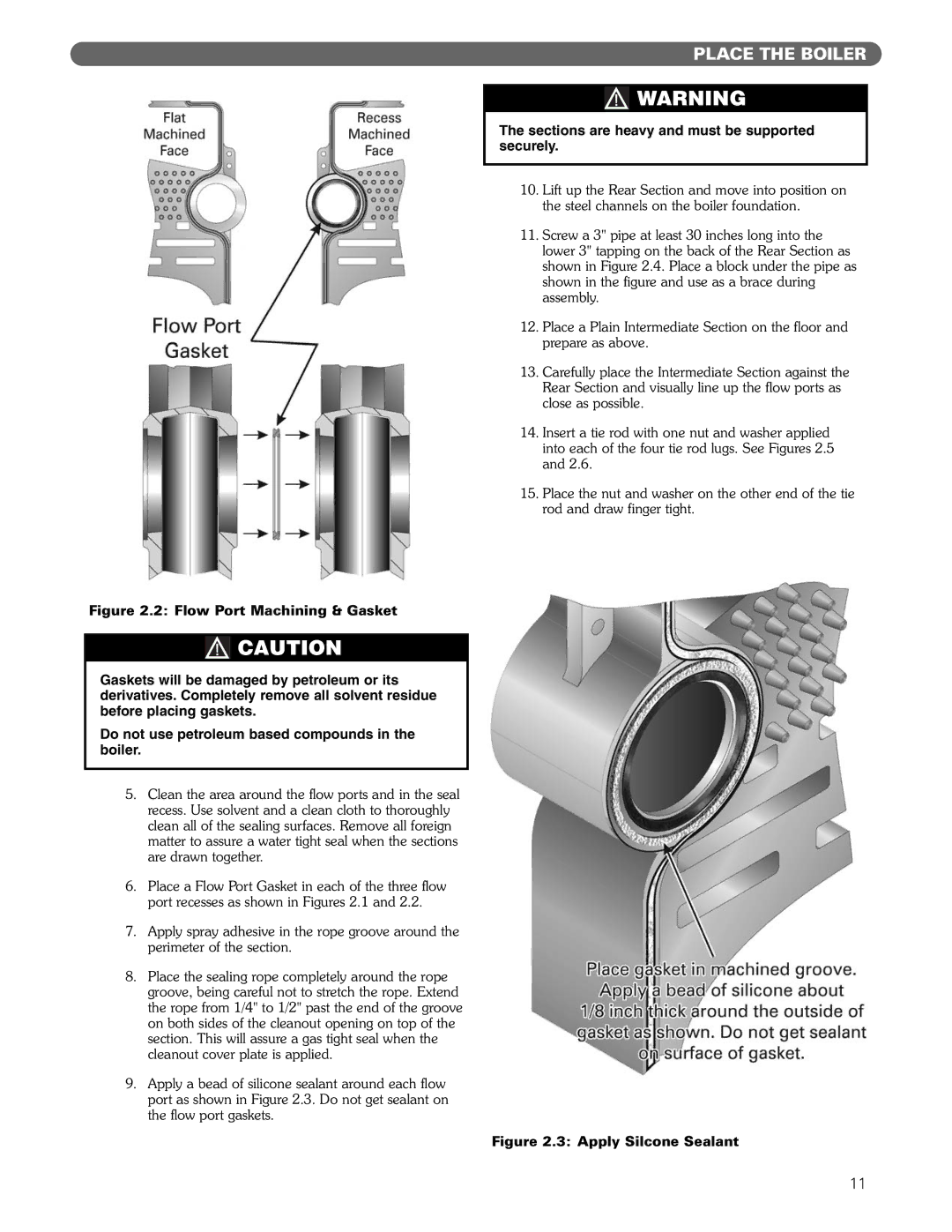

Figure 2.2: Flow Port Machining & Gasket

![]() CAUTION

CAUTION

Gaskets will be damaged by petroleum or its derivatives. Completely remove all solvent residue before placing gaskets.

Do not use petroleum based compounds in the boiler.

5.Clean the area around the flow ports and in the seal recess. Use solvent and a clean cloth to thoroughly clean all of the sealing surfaces. Remove all foreign matter to assure a water tight seal when the sections are drawn together.

6.Place a Flow Port Gasket in each of the three flow port recesses as shown in Figures 2.1 and 2.2.

7.Apply spray adhesive in the rope groove around the perimeter of the section.

8.Place the sealing rope completely around the rope groove, being careful not to stretch the rope. Extend the rope from 1/4" to 1/2" past the end of the groove on both sides of the cleanout opening on top of the section. This will assure a gas tight seal when the cleanout cover plate is applied.

9.Apply a bead of silicone sealant around each flow port as shown in Figure 2.3. Do not get sealant on the flow port gaskets.

Figure 2.3: Apply Silcone Sealant

11