Basics

5. Position the Side Guides

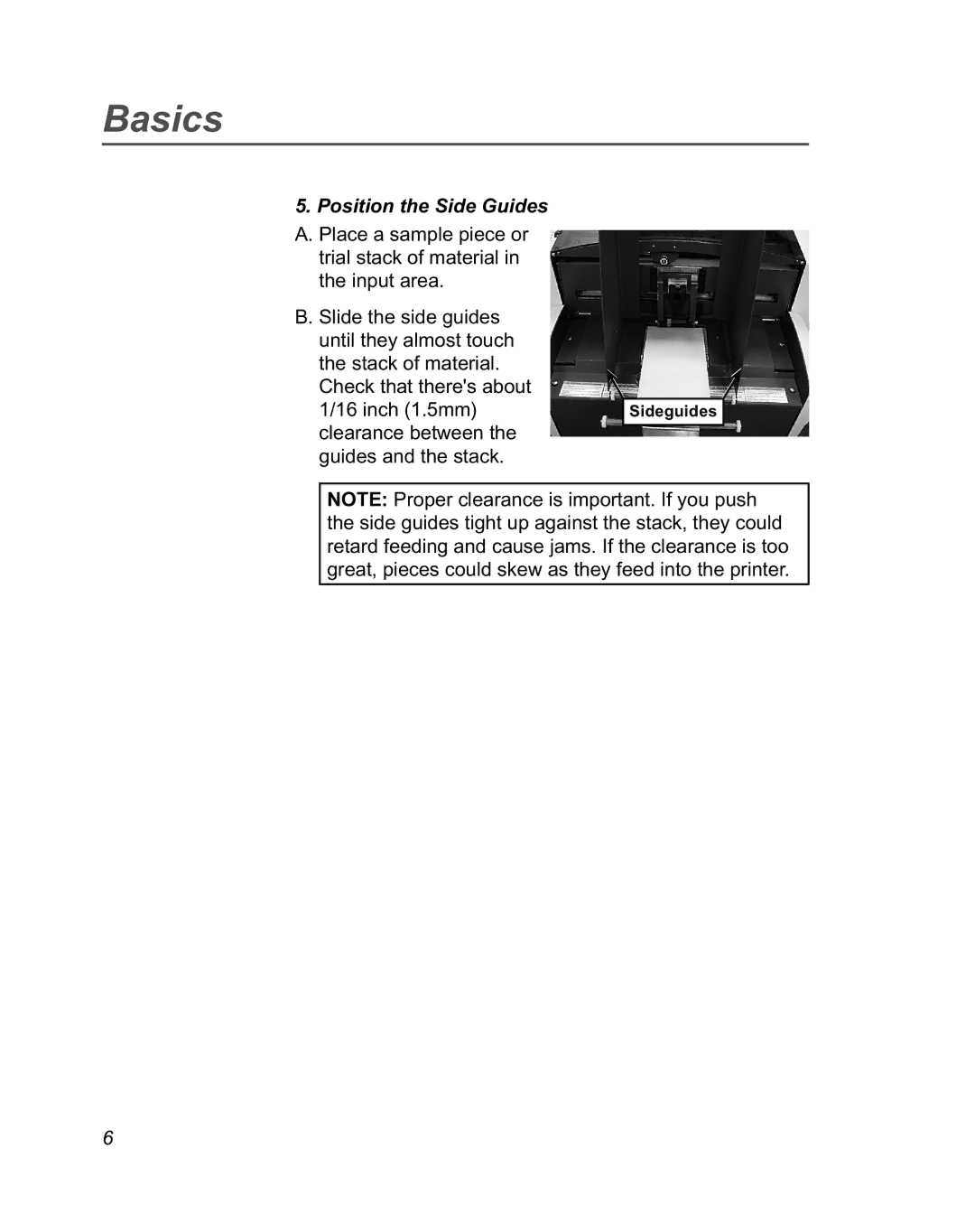

A. Place a sample piece or trial stack of material in the input area.

B. Slide the side guides until they almost touch the stack of material. Check that there's about 1/16 inch (1.5mm) clearance between the guides and the stack.

Sideguides

NOTE: Proper clearance is important. If you push the side guides tight up against the stack, they could retard feeding and cause jams. If the clearance is too great, pieces could skew as they feed into the printer.

6