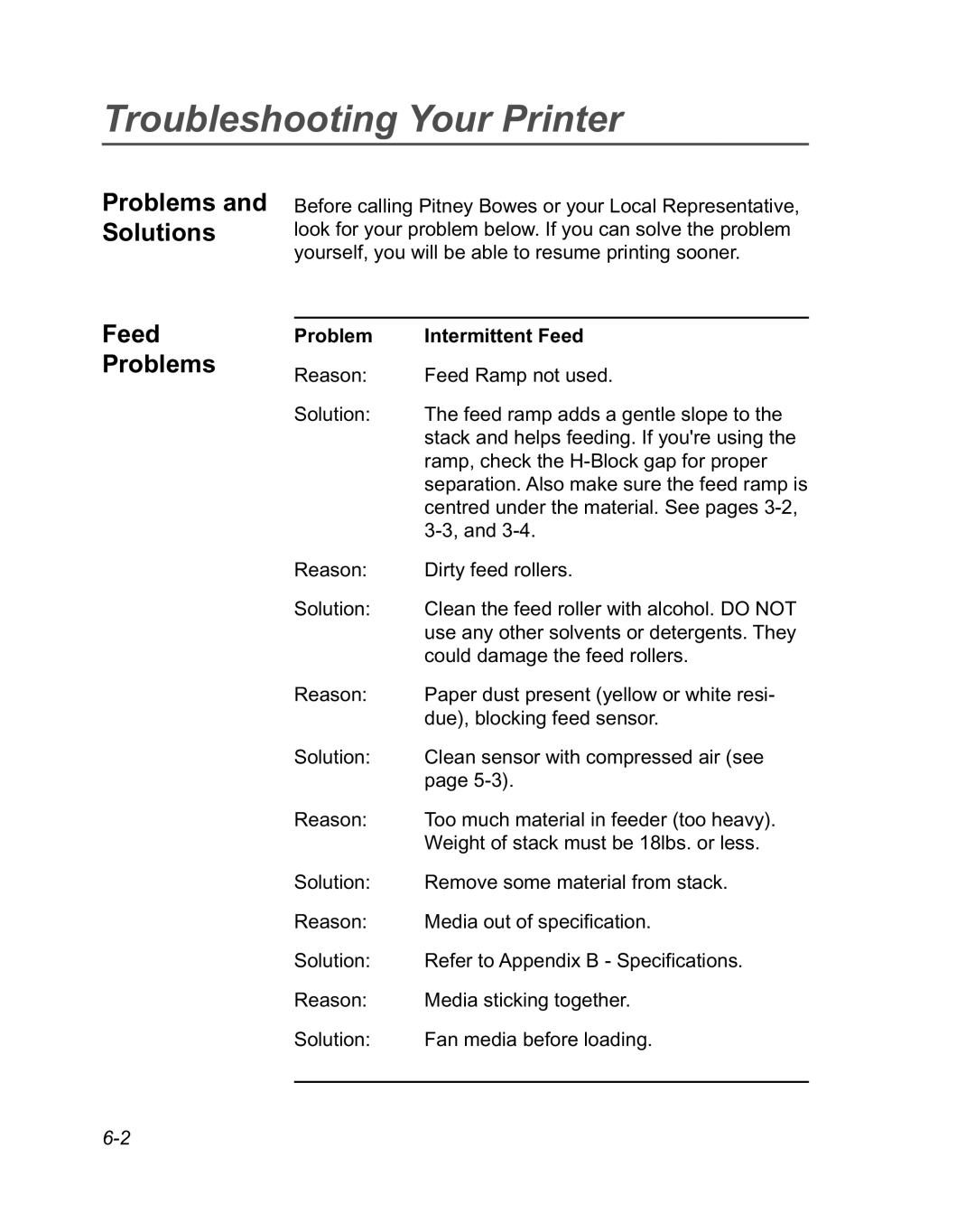

Troubleshooting Your Printer

Problems and Solutions

Before calling Pitney Bowes or your Local Representative, look for your problem below. If you can solve the problem yourself, you will be able to resume printing sooner.

Feed Problems

Problem | Intermittent Feed |

Reason: | Feed Ramp not used. |

Solution: | The feed ramp adds a gentle slope to the |

| stack and helps feeding. If you're using the |

| ramp, check the |

| separation. Also make sure the feed ramp is |

| centred under the material. See pages |

| |

Reason: | Dirty feed rollers. |

Solution: | Clean the feed roller with alcohol. DO NOT |

| use any other solvents or detergents. They |

| could damage the feed rollers. |

Reason: | Paper dust present (yellow or white resi- |

| due), blocking feed sensor. |

Solution: | Clean sensor with compressed air (see |

| page |

Reason: | Too much material in feeder (too heavy). |

| Weight of stack must be 18lbs. or less. |

Solution: | Remove some material from stack. |

Reason: | Media out of specification. |

Solution: | Refer to Appendix B - Specifications. |

Reason: | Media sticking together. |

Solution: | Fan media before loading. |

|

|