Chapter 3 | Menus |

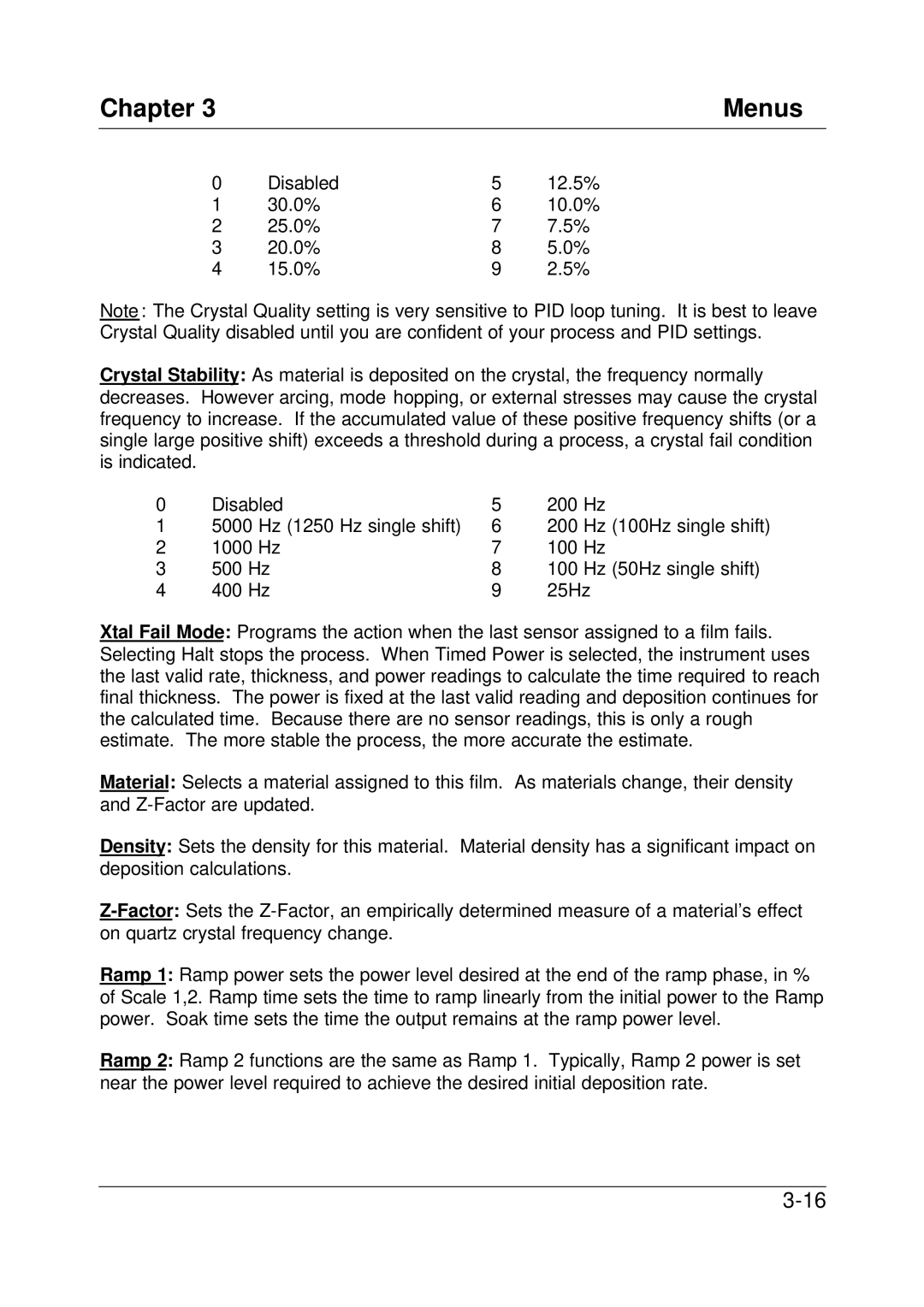

0 | Disabled | 5 | 12.5% |

1 | 30.0% | 6 | 10.0% |

2 | 25.0% | 7 | 7.5% |

3 | 20.0% | 8 | 5.0% |

4 | 15.0% | 9 | 2.5% |

Note: The Crystal Quality setting is very sensitive to PID loop tuning. It is best to leave Crystal Quality disabled until you are confident of your process and PID settings.

Crystal Stability: As material is deposited on the crystal, the frequency normally decreases. However arcing, mode hopping, or external stresses may cause the crystal frequency to increase. If the accumulated value of these positive frequency shifts (or a single large positive shift) exceeds a threshold during a process, a crystal fail condition is indicated.

0 | Disabled | 5 | 200 Hz | |

1 | 5000 Hz (1250 Hz single shift) | 6 | 200 | Hz (100Hz single shift) |

2 | 1000 Hz | 7 | 100 Hz | |

3 | 500 Hz | 8 | 100 | Hz (50Hz single shift) |

4 | 400 Hz | 9 | 25Hz | |

Xtal Fail Mode: Programs the action when the last sensor assigned to a film fails. Selecting Halt stops the process. When Timed Power is selected, the instrument uses the last valid rate, thickness, and power readings to calculate the time required to reach final thickness. The power is fixed at the last valid reading and deposition continues for the calculated time. Because there are no sensor readings, this is only a rough estimate. The more stable the process, the more accurate the estimate.

Material: Selects a material assigned to this film. As materials change, their density and

Density: Sets the density for this material. Material density has a significant impact on deposition calculations.

Ramp 1: Ramp power sets the power level desired at the end of the ramp phase, in % of Scale 1,2. Ramp time sets the time to ramp linearly from the initial power to the Ramp power. Soak time sets the time the output remains at the ramp power level.

Ramp 2: Ramp 2 functions are the same as Ramp 1. Typically, Ramp 2 power is set near the power level required to achieve the desired initial deposition rate.