Chapter 2 | Operation |

The PID parameters control the response of the

The P Term is proportional (or gain), the % process rate change divided by the % input power change. The I Term (integral) sums the rate deviations over time to more accurately achieve the rate setpoint. The D Term (derivative) speeds response to sudden changes in rate. Volumes have been written on determining the proper PID settings. See the section on Loop Tuning later in this chapter for a common PID loop tuning procedure. For now, you should probably leave these values at their defaults.

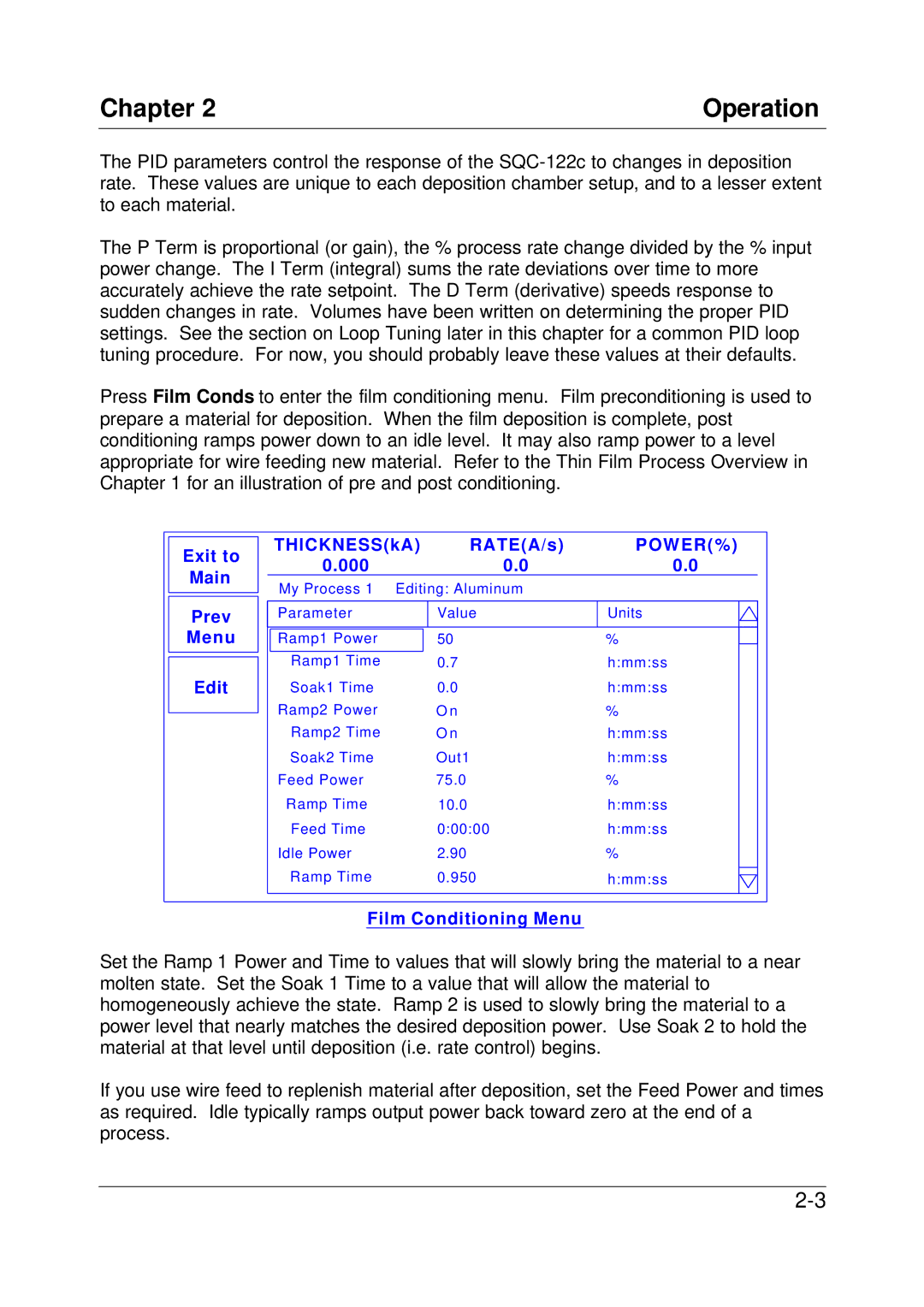

Press Film Conds to enter the film conditioning menu. Film preconditioning is used to prepare a material for deposition. When the film deposition is complete, post conditioning ramps power down to an idle level. It may also ramp power to a level appropriate for wire feeding new material. Refer to the Thin Film Process Overview in Chapter 1 for an illustration of pre and post conditioning.

Exit to Main

Prev Menu

Edit

THICKNESS(kA) |

| RATE(A/s) | POWER(%) | |

0.000 | 0.0 | 0.0 |

| |

My Process 1 Editing: Aluminum |

|

| ||

|

|

|

|

|

Parameter |

| Value | Units |

|

|

|

|

|

|

|

|

|

|

|

Ramp1 Power | 50 | % |

| |

|

|

|

|

|

Ramp1 Time | 0.7 | h:mm:ss |

| |

Soak1 Time | 0.0 | h:mm:ss |

| |

Ramp2 Power |

| O n | % |

|

Ramp2 Time |

| O n | h:mm:ss |

|

Soak2 Time |

| Out1 | h:mm:ss |

|

Feed Power | 75.0 | % |

| |

Ramp Time | 10.0 | h:mm:ss |

| |

Feed Time | 0:00:00 | h:mm:ss |

| |

Idle Power | 2.90 | % |

| |

Ramp Time | 0.950 | h:mm:ss |

| |

| ||||

|

|

|

|

|

Film Conditioning Menu

Set the Ramp 1 Power and Time to values that will slowly bring the material to a near molten state. Set the Soak 1 Time to a value that will allow the material to homogeneously achieve the state. Ramp 2 is used to slowly bring the material to a power level that nearly matches the desired deposition power. Use Soak 2 to hold the material at that level until deposition (i.e. rate control) begins.

If you use wire feed to replenish material after deposition, set the Feed Power and times as required. Idle typically ramps output power back toward zero at the end of a process.