Chapter 2 | Operation |

2.6Running a Process

Once a Process is defined with the desired Layers, and the sensors and source supply are properly connected, the deposition process is ready to run. The next section, on Loop Tuning, describes a method for initial process startup and optimization. This section describes the steps to select, start, and stop a process.

Note: It is best (and safest!) to place the

To select a process, the status bar must be showing Phase: Stopped. If any other phase is displayed, press the Abort SoftKey.

Press Process Menu, then use the scroll knob to highlight the desired process. If the third SoftKey shows Edit when a process is highlighted, then it is already the current process. Otherwise, press Select to set the highlighted process as the current process. You can press Edit to review the current process layers and their associated films. Press Main Screen to return to the main operating screen.

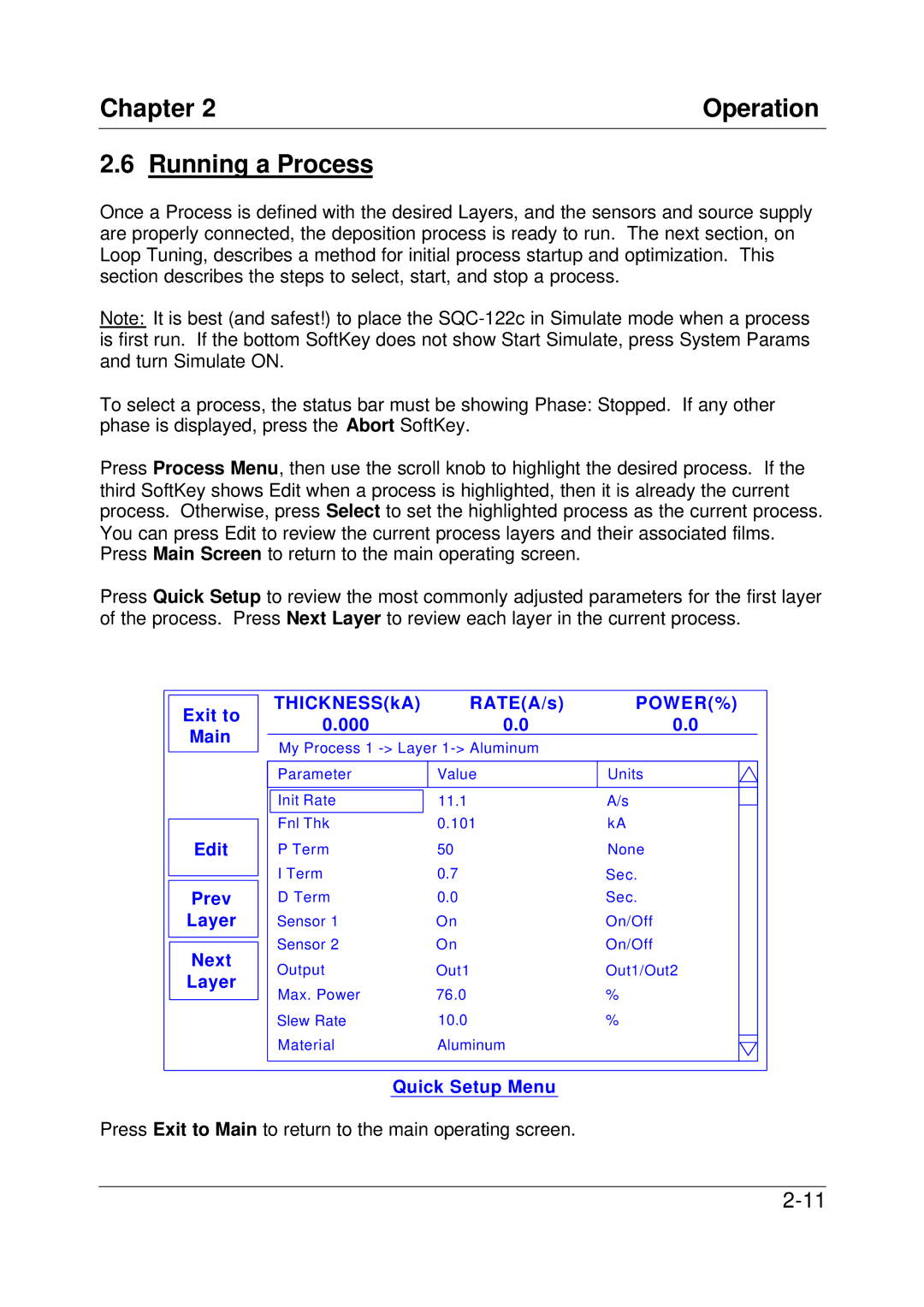

Press Quick Setup to review the most commonly adjusted parameters for the first layer of the process. Press Next Layer to review each layer in the current process.

Exit to Main

Edit

Prev

Layer

Next

Layer

THICKNESS(kA) |

| RATE(A/s) | POWER(%) | |

0.000 | 0.0 | 0.0 |

| |

My Process 1 |

|

| ||

|

|

|

|

|

Parameter |

| Value | Units |

|

|

|

|

|

|

|

|

|

|

|

Init Rate | 11.1 | A/s |

| |

| ||||

|

|

|

|

|

Fnl Thk | 0.101 | kA |

| |

P Term | 50 | None |

| |

I Term | 0.7 | Sec. |

| |

D Term | 0.0 | Sec. |

| |

Sensor 1 |

| On | On/Off |

|

Sensor 2 |

| On | On/Off |

|

Output |

| Out1 | Out1/Out2 |

|

Max. Power | 76.0 | % |

| |

Slew Rate | 10.0 | % |

| |

Material |

| Aluminum |

|

|

|

|

| ||

|

|

|

|

|

Quick Setup Menu

Press Exit to Main to return to the main operating screen.