Chapter 3 | Menus |

Descriptions of each System Parameter follows:

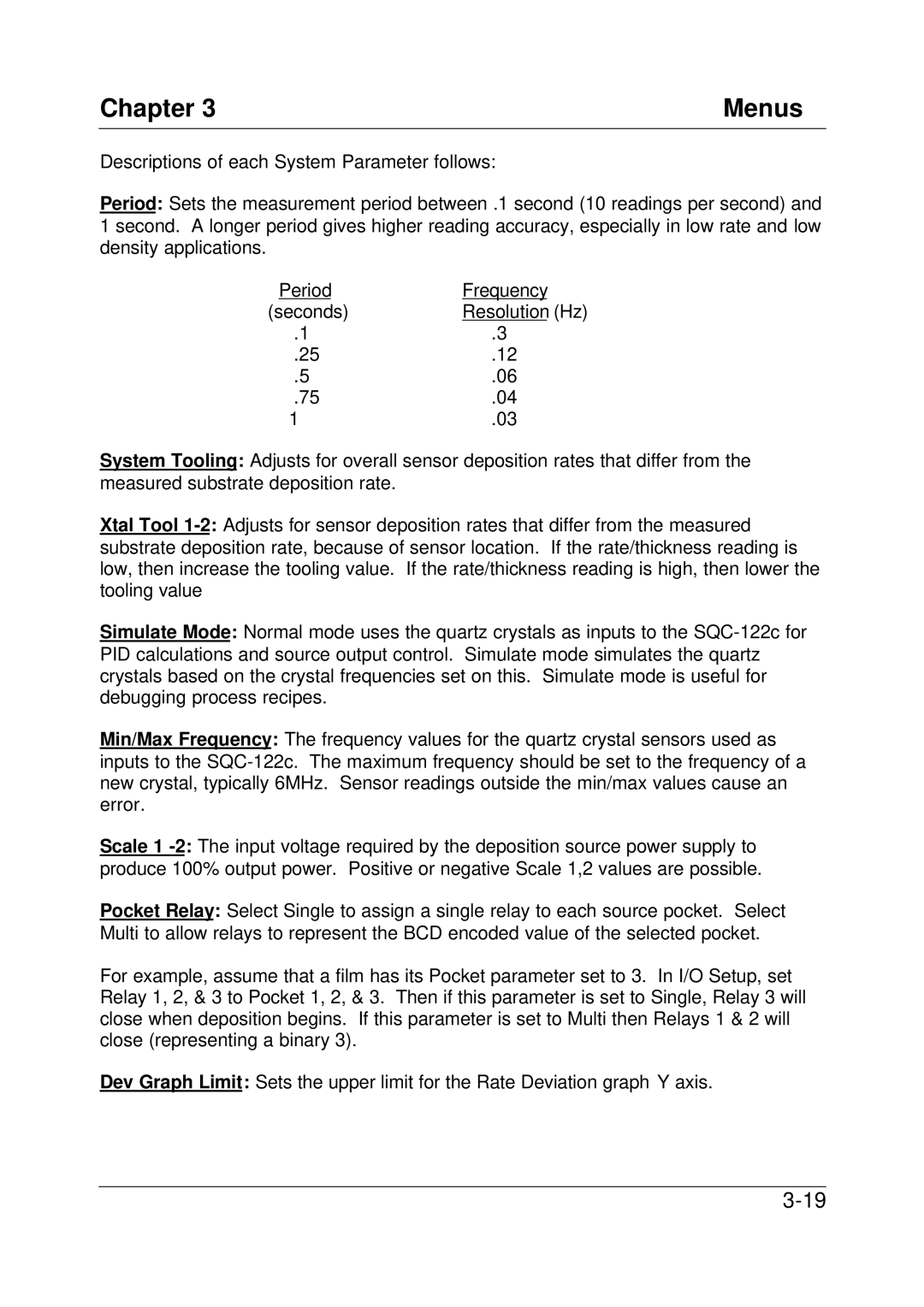

Period: Sets the measurement period between .1 second (10 readings per second) and 1 second. A longer period gives higher reading accuracy, especially in low rate and low density applications.

Period | Frequency |

(seconds) | Resolution (Hz) |

.1 | .3 |

.25 | .12 |

.5 | .06 |

.75 | .04 |

1 | .03 |

System Tooling: Adjusts for overall sensor deposition rates that differ from the measured substrate deposition rate.

Xtal Tool

Simulate Mode: Normal mode uses the quartz crystals as inputs to the

Min/Max Frequency: The frequency values for the quartz crystal sensors used as inputs to the

Scale 1

Pocket Relay: Select Single to assign a single relay to each source pocket. Select Multi to allow relays to represent the BCD encoded value of the selected pocket.

For example, assume that a film has its Pocket parameter set to 3. In I/O Setup, set Relay 1, 2, & 3 to Pocket 1, 2, & 3. Then if this parameter is set to Single, Relay 3 will close when deposition begins. If this parameter is set to Multi then Relays 1 & 2 will close (representing a binary 3).

Dev Graph Limit: Sets the upper limit for the Rate Deviation graph Y axis.