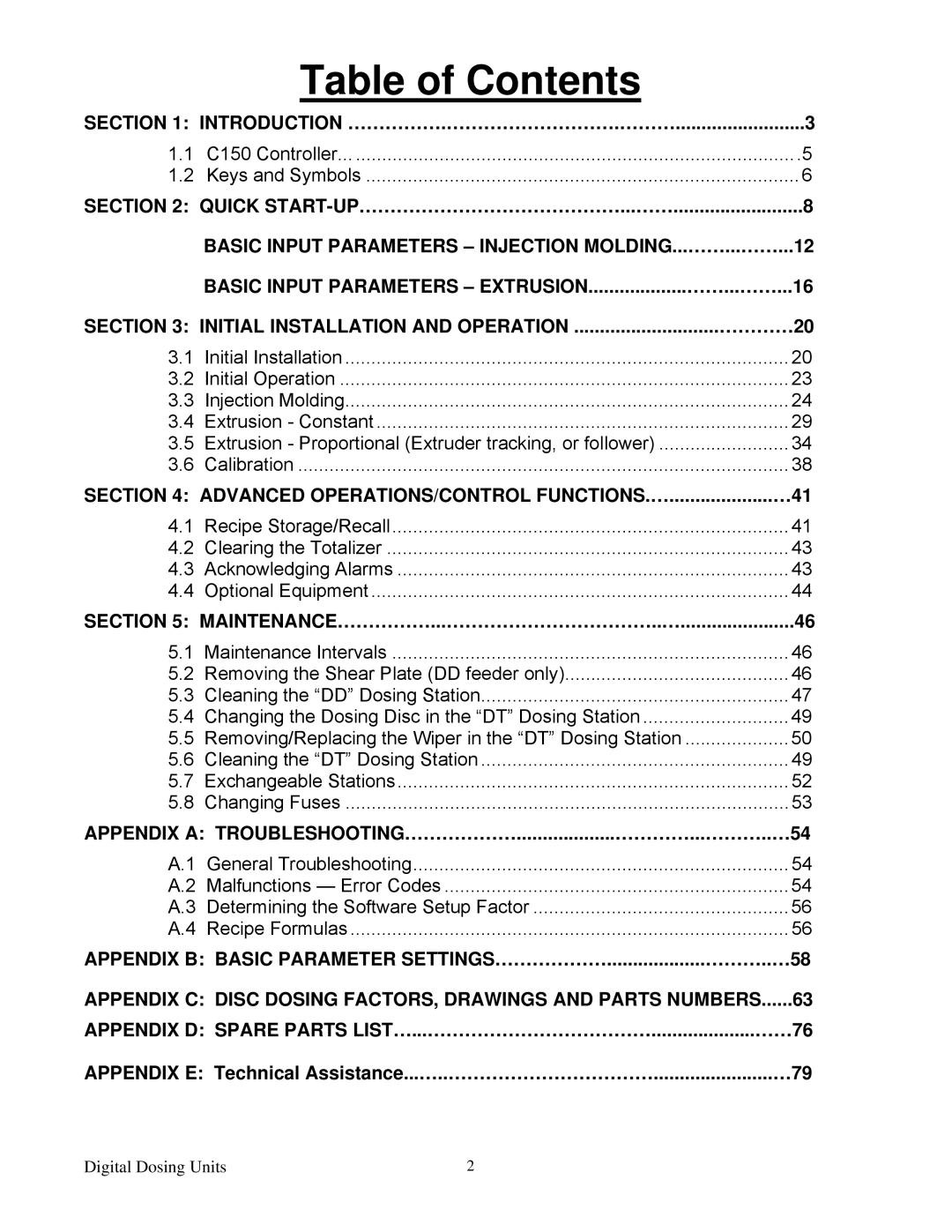

| Table of Contents |

|

SECTION 1: INTRODUCTION …………….……………………….……….........................3 | ||

1.1 | C150 Controller | 5 |

1.2 | Keys and Symbols | 6 |

SECTION 2: QUICK | ||

| BASIC INPUT PARAMETERS – INJECTION MOLDING...……...……...12 | |

| BASIC INPUT PARAMETERS – EXTRUSION...................……...……...16 | |

SECTION 3: INITIAL INSTALLATION AND OPERATION ............................…………20 | ||

3.1 | Initial Installation | 20 |

3.2 | Initial Operation | 23 |

3.3 | Injection Molding | 24 |

3.4 | Extrusion - Constant | 29 |

3.5 | Extrusion - Proportional (Extruder tracking, or follower) | 34 |

3.6 | Calibration | 38 |

SECTION 4: ADVANCED OPERATIONS/CONTROL FUNCTIONS.…....................…41 | ||

4.1 | Recipe Storage/Recall | 41 |

4.2 | Clearing the Totalizer | 43 |

4.3 | Acknowledging Alarms | 43 |

4.4 | Optional Equipment | 44 |

SECTION 5: MAINTENANCE……………...……………………………..…......................46 | ||

5.1 | Maintenance Intervals | 46 |

5.2 | Removing the Shear Plate (DD feeder only) | 46 |

5.3 | Cleaning the “DD” Dosing Station | 47 |

5.4 | Changing the Dosing Disc in the “DT” Dosing Station | 49 |

5.5 | Removing/Replacing the Wiper in the “DT” Dosing Station | 50 |

5.6 | Cleaning the “DT” Dosing Station | 49 |

5.7 | Exchangeable Stations | 52 |

5.8 | Changing Fuses | 53 |

APPENDIX A: TROUBLESHOOTING………………...................…………...………..…54 | ||

A.1 | General Troubleshooting | 54 |

A.2 Malfunctions — Error Codes | 54 | |

A.3 | Determining the Software Setup Factor | 56 |

A.4 Recipe Formulas | 56 | |

APPENDIX B: BASIC PARAMETER SETTINGS………………...................………..…58 | ||

APPENDIX C: DISC DOSING FACTORS, DRAWINGS AND PARTS NUMBERS | 63 | |

APPENDIX D: SPARE PARTS LIST…...………………………………....................……76 | ||

APPENDIX E: Technical Assistance...…..…………………………….......................…79 | ||

Digital Dosing Units | 2 |