4.Electrical connection to process machine:

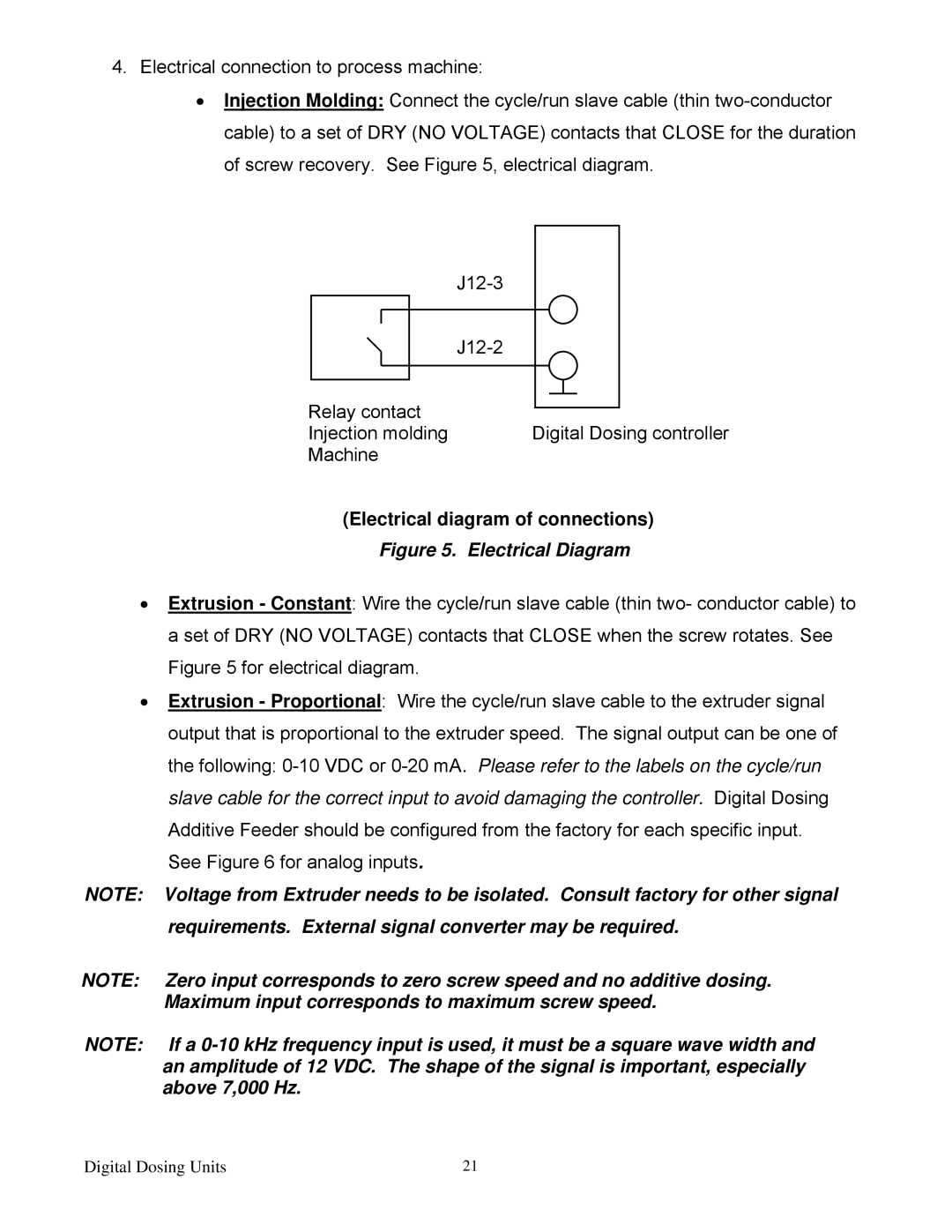

•Injection Molding: Connect the cycle/run slave cable (thin

Relay contact

Injection molding Digital Dosing controller

Machine

(Electrical diagram of connections)

Figure 5. Electrical Diagram

•Extrusion - Constant: Wire the cycle/run slave cable (thin two- conductor cable) to a set of DRY (NO VOLTAGE) contacts that CLOSE when the screw rotates. See Figure 5 for electrical diagram.

•Extrusion - Proportional: Wire the cycle/run slave cable to the extruder signal output that is proportional to the extruder speed. The signal output can be one of the following:

NOTE: Voltage from Extruder needs to be isolated. Consult factory for other signal requirements. External signal converter may be required.

NOTE: Zero input corresponds to zero screw speed and no additive dosing. Maximum input corresponds to maximum screw speed.

NOTE: If a

Digital Dosing Units | 21 |