•To stop the dosing process, press ![]() .

.

•While the unit is dosing, the current recipe can be viewed, but not modified by pressing ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() . The recovery time displayed in the current recipe is the average of the last five shots measured from the molding machine. To change the recipe, the unit must be taken off line by pressing the stop key. The run LED will then go out.

. The recovery time displayed in the current recipe is the average of the last five shots measured from the molding machine. To change the recipe, the unit must be taken off line by pressing the stop key. The run LED will then go out.

NOTE: See Appendix A, Troubleshooting, for information on problems or errors encountered and their resolution.

3.4 Extrusion – Constant (Standard)

In Extrusion Constant operation, the Digital Dosing unit doses material at a constant rate that does not change with extruder speed. The dosing process begins at the startup of the extruder. How close the actual extruder speed is to the input recipe will determine the accuracy of the blend. If the process requires the additive to be dosed in proportion to the process speed, then the Digital Dosing unit must be configured for Extrusion Proportional operation (go to Section 3.5).

Recipe Input – Extrusion - Constant

To enter a recipe for Extrusion Constant, the following process data is required:

•Percentage of additive

•Total throughput rate of the extruder during production

•Calibration weight in grams

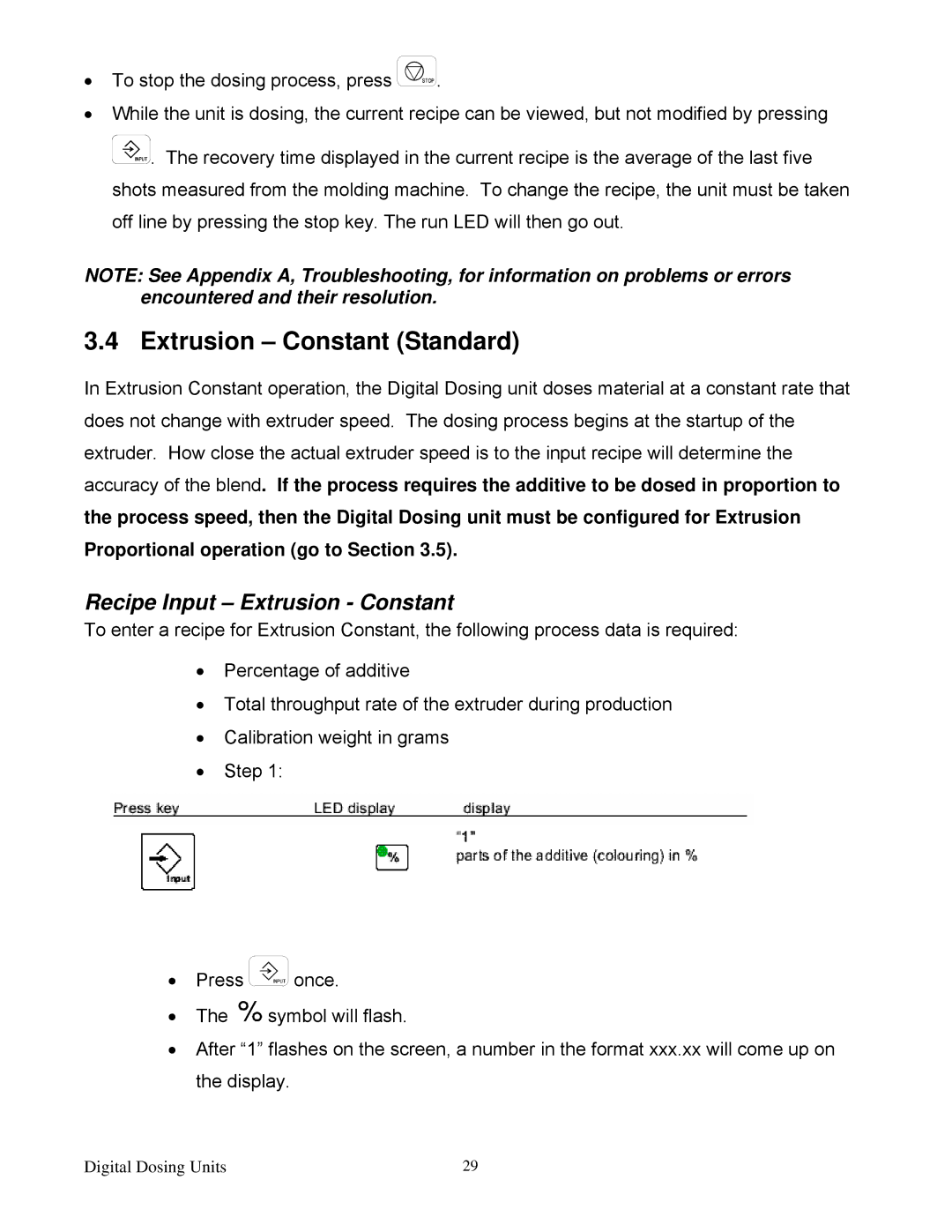

•Step 1:

•Press ![]() once.

once.

•The ![]()

![]() symbol will flash.

symbol will flash.

•After “1” flashes on the screen, a number in the format xxx.xx will come up on the display.

Digital Dosing Units | 29 |