Section 3: Initial Installation and Operation

3.1 Initial Installation

Hopper Piece

Processing |

Machine |

Direction of Material Flow |

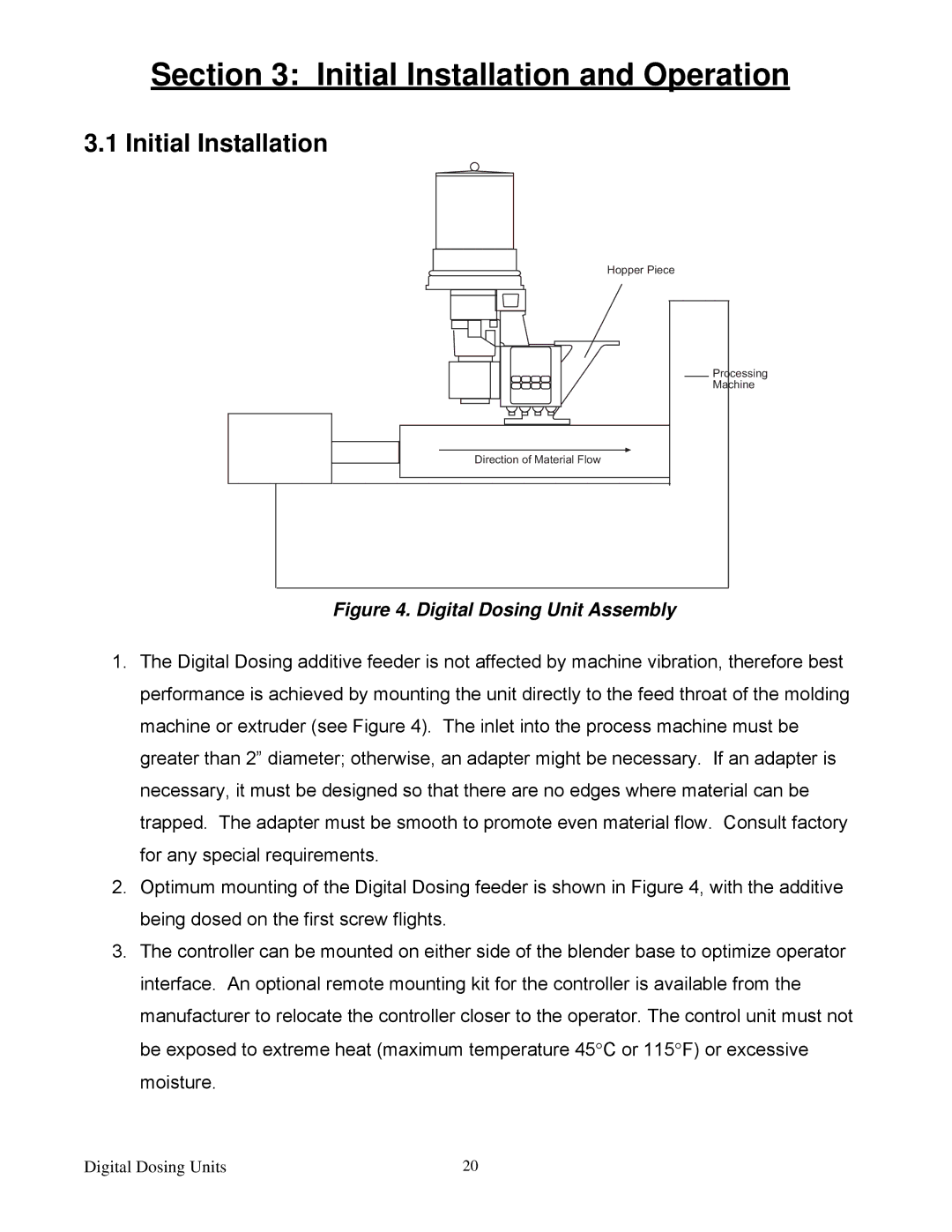

Figure 4. Digital Dosing Unit Assembly

1.The Digital Dosing additive feeder is not affected by machine vibration, therefore best performance is achieved by mounting the unit directly to the feed throat of the molding machine or extruder (see Figure 4). The inlet into the process machine must be greater than 2” diameter; otherwise, an adapter might be necessary. If an adapter is necessary, it must be designed so that there are no edges where material can be trapped. The adapter must be smooth to promote even material flow. Consult factory for any special requirements.

2.Optimum mounting of the Digital Dosing feeder is shown in Figure 4, with the additive being dosed on the first screw flights.

3.The controller can be mounted on either side of the blender base to optimize operator interface. An optional remote mounting kit for the controller is available from the manufacturer to relocate the controller closer to the operator. The control unit must not be exposed to extreme heat (maximum temperature 45°C or 115°F) or excessive moisture.

Digital Dosing Units | 20 |