_ |

|

|

| + |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

| ||||

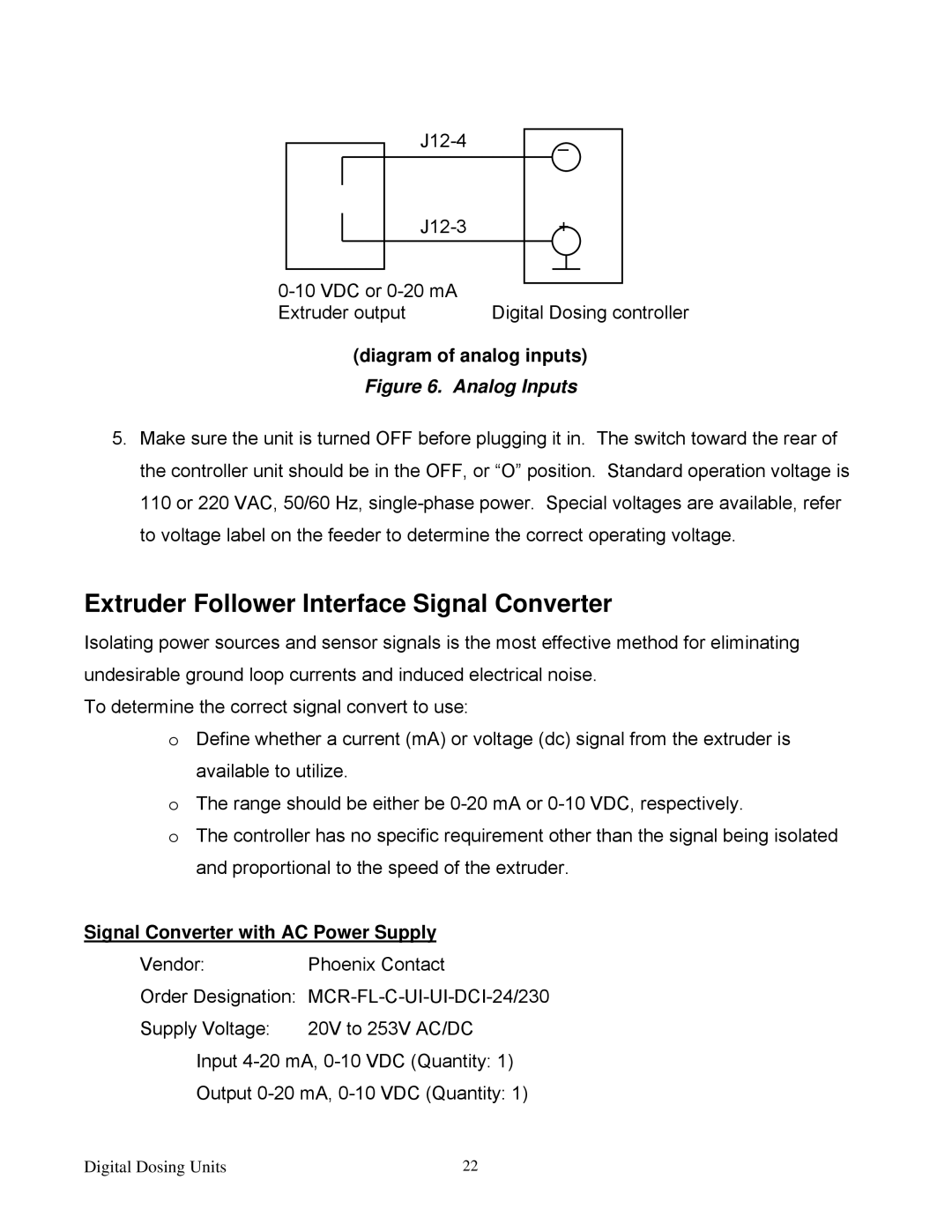

Extruder output | Digital Dosing controller | ||||||||

(diagram of analog inputs)

Figure 6. Analog Inputs

5.Make sure the unit is turned OFF before plugging it in. The switch toward the rear of the controller unit should be in the OFF, or “O” position. Standard operation voltage is 110 or 220 VAC, 50/60 Hz,

Extruder Follower Interface Signal Converter

Isolating power sources and sensor signals is the most effective method for eliminating undesirable ground loop currents and induced electrical noise.

To determine the correct signal convert to use:

oDefine whether a current (mA) or voltage (dc) signal from the extruder is available to utilize.

oThe range should be either be

oThe controller has no specific requirement other than the signal being isolated and proportional to the speed of the extruder.

Signal Converter with AC Power Supply

Vendor: | Phoenix Contact |

Order Designation: | |

Supply Voltage: | 20V to 253V AC/DC |

Input

Output

Digital Dosing Units | 22 |