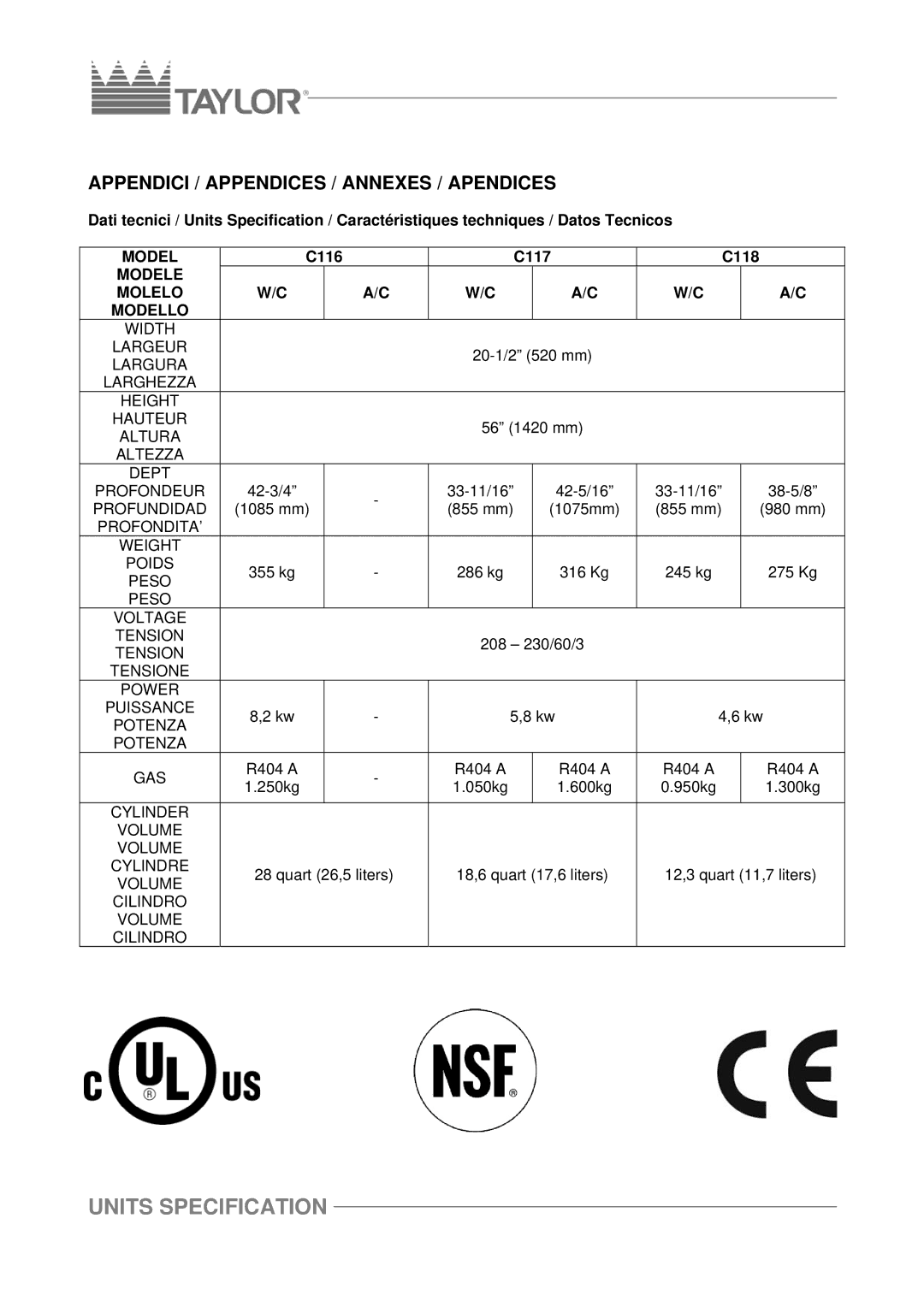

C118, C117, C116 specifications

The Taylor C116, C117, and C118 models represent a series of high-performance vertical machining centers designed for precision engineering and heavy-duty manufacturing applications. These machines are part of Taylor’s commitment to providing advanced solutions for industries ranging from aerospace to automotive.The C116 model is known for its compact design, making it suitable for shop floors with limited space. Equipped with a high-speed spindle that reaches up to 15,000 RPM, the C116 ensures quick material removal and superior surface finishes. Its robust construction utilizes a cast-iron frame, which minimizes vibrations during machining, ensuring consistent precision across long production runs. The machine features a 24-tool automatic carousel, allowing for rapid tool changes and versatility in operations.

Moving to the C117, this model introduces enhanced capabilities with a larger work envelope, accommodating larger parts and heavier workpieces. It is equipped with an advanced Fanuc control system that provides user-friendly programming and real-time monitoring of machining processes. The C117 also offers dual-axis linear motors in the X and Y axes, which significantly increase acceleration and deceleration speeds, enhancing overall productivity. The intelligent thermal compensation system ensures stability and accuracy, effectively managing heat generated during operation.

Lastly, the C118 model takes a step further with its dual spindle configuration, allowing for simultaneous machining of two components. This innovative design boosts productivity, especially in high-volume production environments. The C118 features advanced automation options, including robotic loading systems, which streamline workflow and reduce labor costs. The machine’s rigid tapping capability and high torque at low RPMs make it ideal for tapping operations in tough materials, further expanding its versatility.

Overall, the Taylor C116, C117, and C118 machining centers combine cutting-edge technology with robust design characteristics, catering to a wide array of manufacturing needs. Their features not only improve efficiency and precision but also provide users with the confidence that they can tackle complex machining tasks with reliability. As industries continue to evolve, these models stand as testament to Taylor's dedication to innovation and quality in the machining sector.