Compact 4-Way Air Discharge Cassette Type

Contents

Safety Caution

Check the following items after reinstallation

Catch the inner cables

Fire is caused at user’s side

Metal section Earth position

Safety Caution Concerned to New Refrigerant

Pipe Materials

Piping

Flare nut

R410A Conventional air Air conditioner installation

Conditioner installation

Tools

General tools Conventional tools can be used

Recharge of Refrigerant

Environment

4mm-hexagonal wrench is required

Cylinder with siphon

Space required for Installation and servicing

Wired remote

Construction Views External Views

Drain-up standing-up size

Wiring Diagram

For Indoor unit

MCC-1402

Control P.C. board

Parts Rating

Parts Rating

Name of Each Part

Model

Parts Name of Remote Controller

Display section

Remote controller sensor

Operation section

Button

Wind direction and Swing

Turn on the main power switch and/or the leakage breaker

Correct Usage

Preparation

Stop

Start

Automatic Operation Super Heat Recovery Type Only

When restarting the operation after stop

Timer Operation

Timer operation

Cancel of timer operation

To select SET Time

Adjustment of Wind Direction

How to set up the air direction

How to start swinging

How to stop swinging

Information

Air Conditioner Operations and Performance

When the Following Symptoms are Found

Standby

Precautions for Safety

New Refrigerant Air Conditioner Installation

To Disconnect the Appliance from Main Power Supply

Connect all of the installation wiring correctly

Selection of Installation Place

Installation space

Installation space

Installable ceiling height list

Dimensional view

Installation of Indoor Unit

Case of wireless type

Ceiling opening and installation of hanging bolts

Installation of ceiling panel Sold separately

Installation of hanging bolt

Installation of remote controller Sold separately

Drain Piping Work

Piping material and dimensions

Refrigerant Piping

Thermal insulating process

Permissible pipe length and permissible height difference

Electric Work

Connection of refrigerant pipe

Airtight test/Air purge, etc

Open fully valves of the outdoor unit Gas leak check

Power supply specifications

Indoor unit power supply *1

Indoor/Outdoor inter-unit wiring, Central controller wiring

Remote controller wiring *4

Applicable Controls

Case of installation to high ceiling

Case of remote controller-less Group control

Change of lighting time of filter sign

Increased heating effect

How to execute test operation

Case of wireless remote controller

Case of wired remote controller

Test RUN

Troubleshooting

Confirmation of error history

Check code list

Confirmation and check Check method

Troubleshooting

Error detected by TCC-LINK central control device

Maintenance

Daily maintenance

New check code

Way Air Discharge Cassette Type

Refrigerating Cycle Diagram

Functional part name Functional outline

Control Specifications

Outline of specifications Remarks

Remote controller Control outline Command

Control Outline

Reset conditions

Value

TCB-AX21E

Central control mode 4 Cannot select mode

Central control mode 1 Cannot operate

Central control mode

Procedure Execute the setup operation while the unit stops

Applied Control

Description At shipment

HEAT, Heat → Cool

Remote location ON/OFF control box TCB-IFCB-4E

Applied Control in Indoor Unit

Indoor unit capacity

Ventilating fan control from remote controller

Wiring

Function

Operation

Power peak-cut from indoor unit

Using the setup temp

Button, set to the setup data

Leaving-ON prevention control

Troubleshooting

Troubleshooting Summary

Before troubleshooting

Troubleshooting procedure

Check code list

Check Method

Auxiliary code

Judging device

MG-SW

Sensor block display

Error detected by TCC-LINK central control device

Check code Outdoor 7-segment display Auxiliary code

Check code

Troubleshooting by Check Display on Remote Controller

Case of wired remote controller RBC-AMT31E

Confirmation of error history

Procedure Description

Case of central remote controller TCB-SC642TLE

Check code

Outdoor 7-segment display

Check code Auxiliary code

Remote

Setup method of No. capacity-over Detection

Check code

Main Outdoor 7-segment display Remote

Convenient functions

Main Outdoor 7-segment display

Check code Auxiliary code

Remote

Detected

Remote Check code

Check item position

Position Remote

Status Error detection condition Check item position

Detected Main

Check code Main Outdoor 7-segment display

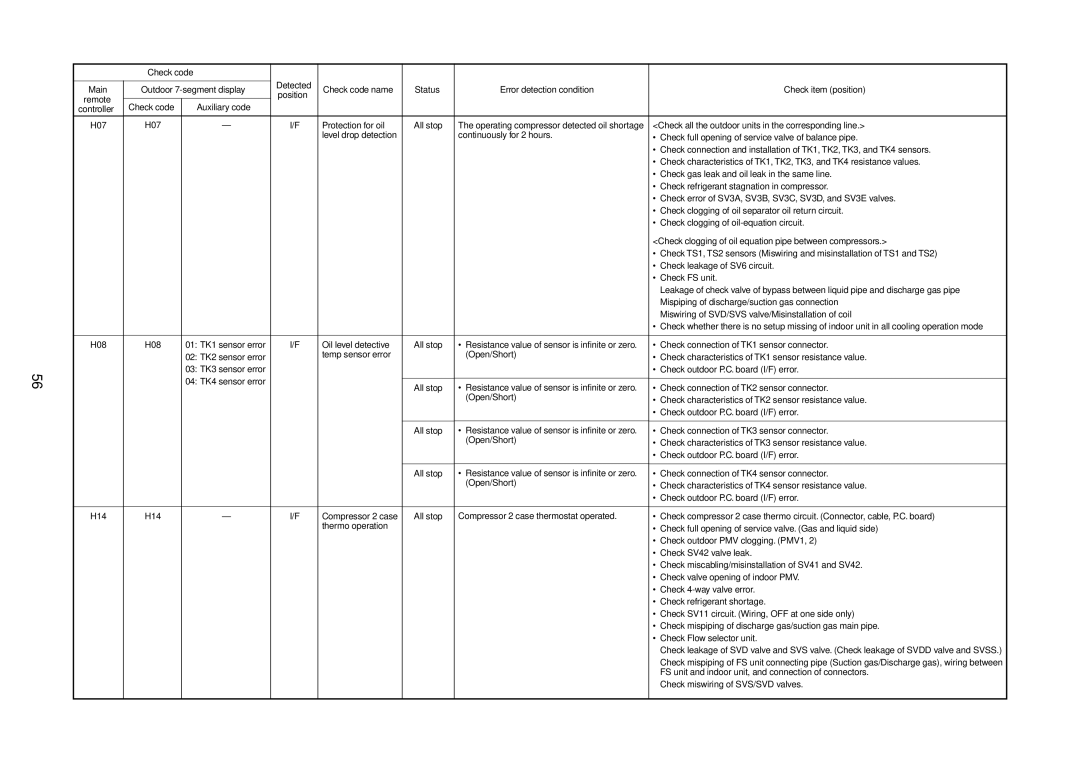

H07

Check all the outdoor units in the corresponding line

Check clogging of oil equation pipe between compressors

Check code Main Outdoor 7-segment display Remote

H16

L30 Detected indoor address L31

P01 P03 P04

Heating

TS error judgment standard temperature

Name

Remote Check code Auxiliary code

Error detection condition Check item position

Outdoor 7-segment display Check code name

Outdoor 7-segment display Detected position

Device Check code

Display on

Central control

How to check inverter output

How to check resistance of compressor winding

How to check the outdoor fan motor

Measured position Criteria

Diagnosis Procedure for Each Check Code

E03

E04

E02

E06 Decreased number of indoor units

E07

E08

E12

E15

E09 Duplicated master

E16

E18

E19

Reference

∗ 1 How to clear the error

E20

E23

E25

E31

F01

F02

F03

F04 TD1 sensor error

F05 TD2 sensor error

F06 TE1 sensor error

F08 To sensor error

F29 Indoor other error

F15 Outdoor temp sensor miscabling

TE1, TL

F23

F31

H02

H01

H03

H06 Low-pressure protective operation

Clogging check for SV3D valve

Leakage check for SV3C valve

Clogging for SV3E valve

Clogging check for oil-equalization circuit

H08

Oil level detective circuit system error

TK3 temperature detective circuit error

H16 TK4 temperature detective circuit error

L04

L05

L03

L07 Group line in individual indoor unit

L10

L17

L08

L18

L29

L20

L28

P01 Indoor fan motor error

L30 Interlock in indoor unit

P03

L31

P05 Open phase, negative phase

P04 Actuation

High-pressure SW

Auxiliary code Compressor 1 side

P07 Heat sink overheat error

P10 Indoor overflow error

Indoor fan motor error

P12

P13 Outdoor liquid back detection error 1. PMV1/PMV2 error

P15

Gas leak detection

TS condition Auxiliary code

Discharge temp TD2 error

P15 Gas leak detection

P17

TD condition Auxiliary code

Judgment criteria

P19 Way valve operation error

P20 High-pressure protective operation

P22 Outdoor fan Ipdu error

Auxiliary code 0 ∗

P26 Tr short-circuit protection error

Detective circuit error

P29

P31

Check procedure in case of stop with trouble

How to read the check monitor Segment display

Segment Display Function

Segment display on the outdoor unit Interface P.C. board

SW01 SW02 SW03 Display contents

There is auxiliary code Check code ∗ ∗ ∗ for 3 seconds

Data display of outdoor cycle Displayed on each outdoor unit

SW03 SW02 Indoor address Segment display a

Sensor Characteristics

Temperature sensor characteristics

W01 SW02 SW03 Display contents Segment display

Segment display A, B

Configuration of Control Circuit

Wired remote controller Up to 2 units

Weekly timer

Indoor Unit

Compact 4-way Air Discharge Cassette Type

Connection of wireless remote controller

Kit

Wireless

Cassette Type Controller

Remote

Compact4-way Air Discharge Connection of both remote

Air Discharge

Type

MCC-1402 Compact 4-way

Cassette

Optional Connector Specifications of Indoor P.C. Board

Function Connector Pin Specifications Remarks

Part name Procedure Remarks

Detachments

Preparing work

Attachment

100

No. Part name Procedure Remarks

101

102

No. Part name Procedure

103

Fan guard 1. Detachment

Bell mouth 1. Detachment

104

Fan motor 1. Detachment

105

Drain pump 1. Detachment

Details of sensor lead wire drawing

106

Arrow view B

Details of a part

Heat

Exchanger Recover refrigerant gas

107

10. P.C. Board Exchange Procedures

Exchange of P.C. Board for Indoor Service

Exchange procedure

108

Procedure 1 Readout setup contents from Eeprom

Remote controller operation diagram

Procedure 2 Exchange of P.C. board for service

110

Procedure 3 Writing-in of setup contents to Eeprom

Eeprom layout

Make a note of the setup contents. Item code list Example

Exploded Views and Parts List

Ceiling Panel

113

Description

Compact 4-way Air Discharge Cassette Type

MMU-AP0071MH, AP0091MH, AP0121MH, AP0151MH, AP0181MH

211

114

0071MH 0091MH 0121MH 0151MH 0181MH

115

Description Remarks Model Name

116

Description Model Name

Toshiba Carrier Corporation