10-8-5. Checking Method for Each Part

No. | Part name |

| Checking procedure |

|

|

|

|

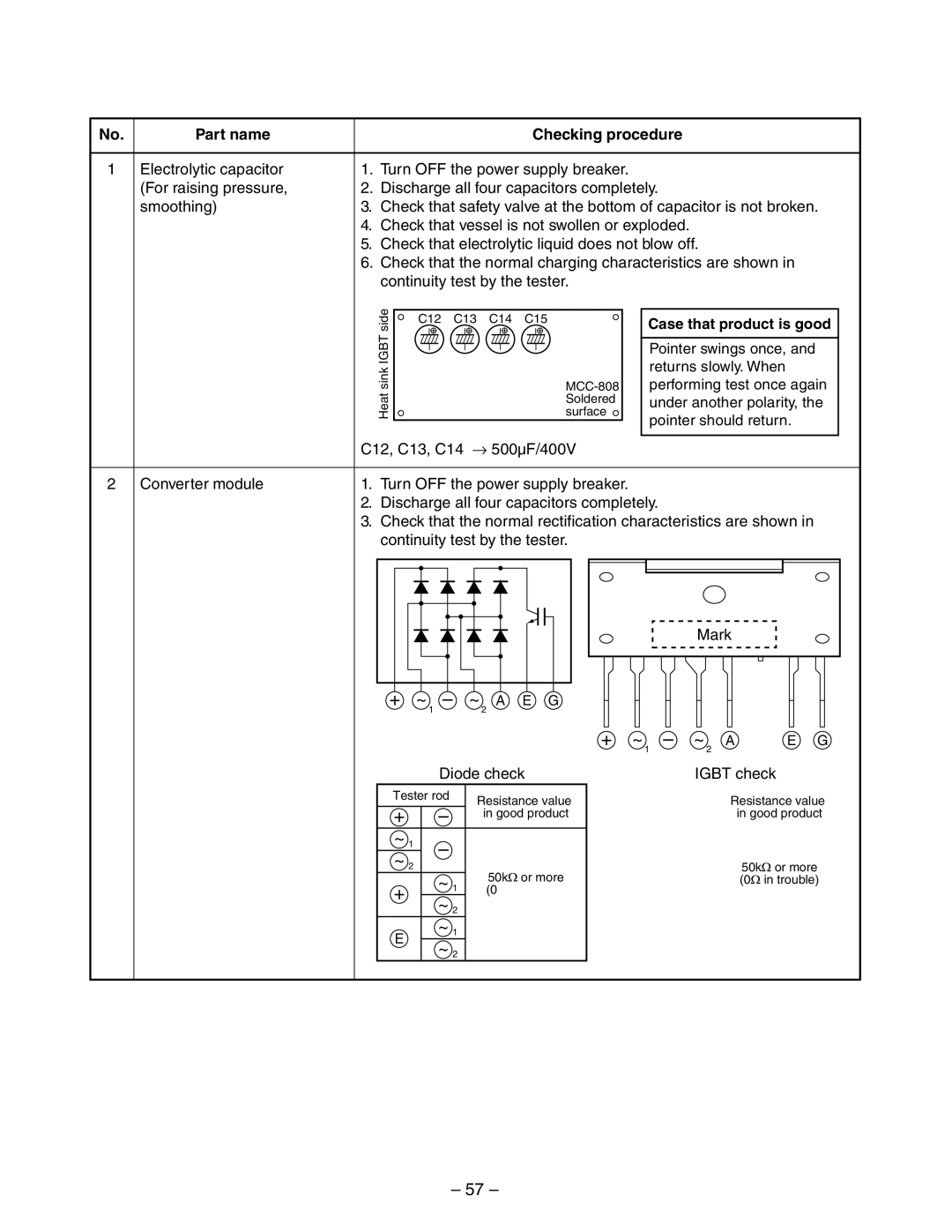

1 | Electrolytic capacitor | 1. | Turn OFF the power supply breaker. |

| (For raising pressure, | 2. | Discharge all four capacitors completely. |

| smoothing) | 3. | Check that safety valve at the bottom of capacitor is not broken. |

4.Check that vessel is not swollen or exploded.

5.Check that electrolytic liquid does not blow off.

6.Check that the normal charging characteristics are shown in continuity test by the tester.

| side | C12 C13 | C14 C15 | Case that product is good |

| IGBT |

|

| Pointer swings once, and |

|

|

|

| |

| sink |

|

| returns slowly. When |

|

|

| performing test once again | |

| Heat |

| surface | under another polarity, the |

|

|

| Soldered | |

|

|

|

| pointer should return. |

| C12, C13, C14 → | 500µF/400V |

| |

2 Converter module | 1. Turn OFF the power supply breaker. |

| ||

2.Discharge all four capacitors completely.

3.Check that the normal rectification characteristics are shown in continuity test by the tester.

|

|

|

|

|

|

|

|

| Mark |

|

| |

+ | ~ | – | ~ | A | E | G |

|

|

|

|

|

|

|

| 1 |

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| + | ~ | – | ~ | A | E | G |

|

|

|

|

|

|

|

| 1 |

| 2 |

|

|

|

| Diode check |

|

| IGBT check | |||||

Tester rod |

| Resistance value | Tester rod | Resistance value | ||||||

+ |

| – |

| + |

| – | ||||

|

| in good product |

| in good product | ||||||

~ 1 | – |

|

|

| ~ 2 | E |

|

| ||

~ |

|

|

|

| G |

|

|

| ||

2 | ~ |

| 50k | or more |

|

| 50k | or more | ||

+ |

| 1 | ~ | 1 |

| (0 | in trouble) | |||

| (0 | in trouble) | A |

|

| |||||

| ~ 2 | ~ |

|

|

| |||||

|

|

|

| 2 |

|

|

| |||

E |

| ~ | 1 |

|

|

|

|

|

|

|

| ~ 2 |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

– 57 –