AIR-CONDITIONER

Contents

10-2

10-1

10-3

10-4

Explanation of illustrated marks

Explanation of indications

Confirmation of warning label on the main unit

Indication Explanation

Never recover the refrigerant into the outdoor unit

∗ For details, refer to the parts list

Do not modify the products

For spare parts, use those specified ∗

Metal section Earth position

Check the following items after reinstallation

Side

Limit even if the refrigerant leaks

Pipe Materials

Safety Caution Concerned to New Refrigerant

Copper pipe Piping

Flare nut

Used tool Usage

General tools Conventional tools can be used

R410A Conventional air

Digital Inverter

Indoor Unit

Way Air Discharge Cassette Type

SP562AT-E SP802AT-E

Super Digital Inverter

RAV SM562BT-E SM802BT-E

Concealed Duct Type

Super Digital Inverter

RAV SM562CT-E SM802CT-E

Under Ceiling Type

Super Digital Inverter

Indoor unit

Twin Type

16.7/14.6

RAV SM562AT-E SM802AT-E

SP562AT-E SP802AT-E

RAV-SM562AT-E, RAV-SM802AT-E

Operation characteristic curve Digital Inverter

Cooling Heating

Current

RAV-SP1102AT-E

Operation characteristic curve Super Digital Inverter

Outdoor temp. ˚C

Capacity variation ratio according to temperature

Ratio Capacity

Tap

Pressure

High

Low Static

Tap Low

Static Pressure Tap

RAV-SM562UT-E, RAV-SM802UT-E

188

RAV-SM1102UT-E, RAV-SM1402UT-E, RAV-SP1102UT-E

Suction port canvas Separate sold

Dimension

RAV-SM562CT-E, RAV-SM802CT-E, RAV-SM1102CT-E, RAV-SM1402CT-E

Space required for service

365

RAV-SP1102AT-E, RAV-SP1402AT-E

RAV-SM562UT-E, RAV-SM562BT-E, RAV-SM562CT-E / RAV-SM562AT-E

Outdoor unit

Indoor Outdoor

RAV-SM802UT-E, RAV-SM802BT-E, RAV-SM802CT-E / RAV-SM802AT-E

Outer dia. Ø B

50m

Outer dia. B

To sensor SKV-18D26 TD sensor

RAV-SM562UT-E, RAV-SM562BT-E, RAV-SM562CT-E / RAV-SP562AT-E

Outer dia. ØB TS sensor Strainer Modulating

RAV-SM802UT-E, RAV-SM802BT-E, RAV-SM802CT-E / RAV-SP802AT-E

Refrigerant pipe At gas side Outer dia. Ø a Ball valve

TCJ sensor Distributor

Indoor unit

LM2 3

LM1 3

Color

Identification

Color

Indoor Unit

LM 3

Identification

MCC-5009

Board

SM562AT-E, RAV-SM802AT-E

Color Identification

GRY Gray YEL Yellow

MCC-1438

Board

MCC-1531

SUB P.C. board

RAV-SP562AT-E, RAV-SP802AT-E

SUB P.C. board

RAV-SP1102UT-E

Parts name Type Specifications

RAV-SM1102UT-E, RAV-SM1402UT-E

MP24GA1

RAV-SM1102AT-E

RAV-SM562AT-E

RAV-SM802AT-E

RAV-SM1402AT-E

RBC-U21PG W E2 Ceiling panel

TCB-DP22CE2 Drain up kit

TCB-DP11E2 Drain up pump

RAV-SM560AT-E, RAV-SM560UT-E, RAV-SM560BT-E

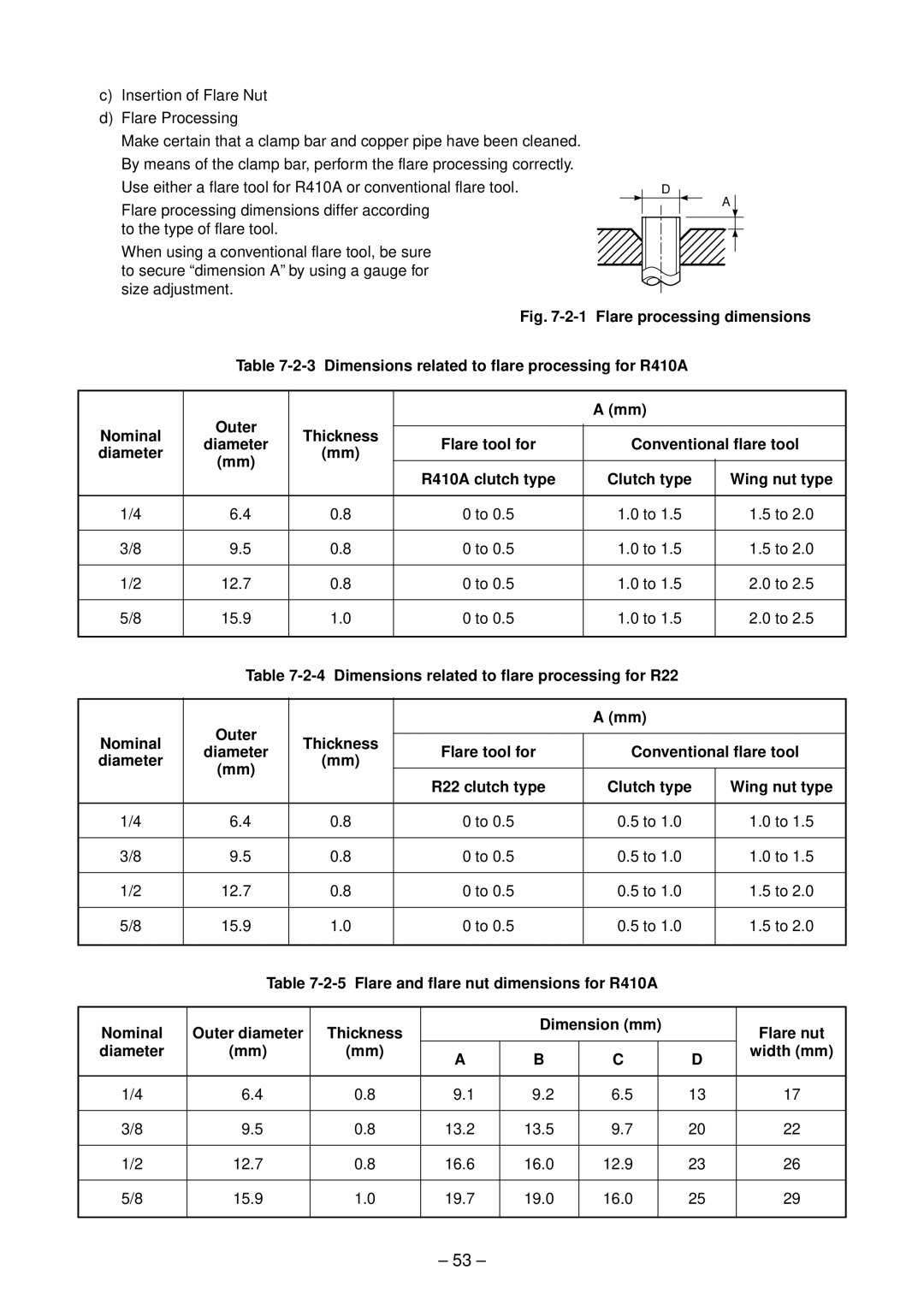

Piping Materials and Joints Used

Safety During Installation/Servicing

1 Thicknesses of annealed copper pipes Thickness mm

Processing of Piping Materials

Outer diameter mm R410A R22

12.7 15.9

R410A clutch type Clutch type Wing nut type

Flare tool for Conventional flare tool

R22 clutch type Clutch type Wing nut type

Diameter Width mm

13.0 13.5 12.7 16.2 16.0 12.9 15.9 19.4 19.0 23.3 24.0 19.2

43˚to 45˚

Nm kgfm

Wrenches available on the market

Refer to the 4. Tools

Required Tools

Flux

Materials for Brazing

Brazing

Characteristics required for flux

Types of flux

Piping materials for brazing and used brazing filler/flux

Indoor unit

Main Sub master remote controller

Indoor Control Circuit

Outline of specifications Remarks

Cool

Setting at shipment

Heating Auto

Operation

Heat

Tcj Zone

Control temp C

All modes

Arning

Cooling/dry operation In heating/fan operation

Frequency fixed In case of wired remote controller

Operation Prohibited

Last push priority

Center

Remarks

Outline of specifications

Normal control

Circuit Board

Indoor Print

Ay Air

Concealed Duct Type / Under Ceiling Type

Pulse Motor Valve P.M.V. control

Discharge temperature release control

Current release control

For the cooling only models

Outdoor Controls

Indoor P.C. Board Optional Connector Specifications

Print Circuit Board

Board Comparison Table for Digital Inverter

RAV -SM562AT-E

MCC-5009

SM802AT-E Board

Iewed fromparts

SP802AT-E

MCC-1531

RAV -SM1102AT

SM1402AT-E / RAV

MCC-1531

RAV -SP562AT-E, RAV RAV -SM1102AT-E, RAV

Ipdu MCC-1438

SM1402AT-E

SP1402AT-E

Pulse Modulating V alve PMV control

Outline of Main Controls

Outdoor fan control

Operation with WE

Allocations of fan tap revolutions rpm

TE ˚C TD ˚C

Trouble of TE sensor

Coil heating control

To ˚C

TE ˚C

Start of heating operation

Defrost control

TE ºC

Zone

Troubleshooting procedure

Summary of Troubleshooting

Ired remote controller type Before troubleshooting

Trouble Confirmation of lamp display

Error mode detected by indoor and outdoor units

Check Code List

Cause of operation Status of air Condition

Error mode detected by central remote controller

Error mode detected by remote controller

SW801 LED display in bit 1, bit 2 OFF

Error Mode Detected by LED on Outdoor P.C. Board

Check code

¡ Go on l Go off ¥ Flash 5Hz

E01 error

Troubleshooting Procedure for Each Check Code

E09 error

Check Code

E04 error

E18 error

E10 error

E08, L03, L07, L08 error

L09 error

L30 error

L20 error

P10 error

F10 error

CN334

P12 error Only for 4-way air discharge cassette type models

CN333

P22 error

F02 error

P19 error

P26 error

F01 error

H03 error

P29 error

F08 error

F06 error

F04 error

H02 error

L29 error

H01 error

P03 error

P04 error

Same as others Correct connection of connector

C06 error Central controller

P31 error Sub indoor unit

E03 error Master indoor unit

F29 error / 12 error

TA sensor TC, TCJ sensor Caracteristics-2 Caracteristics-1

100

Caracteristics-3

20 TE, TO, TS sensor

101

Replacement Procedure

H2 Replacement of service P.C. board

H1 Readout of the setup data from Eeprom

Contents

102

R3 Writing of the setup contents to Eeprom

104

Memorandum for setup contents Item code table Example

Type Item code

Indoor unit capacity Item code

Wired remote controller

Test Run Setup on Remote Controller

105

RAV-SM562UT-E, RAV-SM802UT-E, RAV-SM562BT-E, RAV-SM802BT-E

106

Use either Cool or Heat operation mode for test operation

107

Case of wireless remote controller

Item No. DN table Selection of function

108

Indoor unit is controlled by 2 remote controllers

Cabling and Setting of Remote Controller Control

Setup method

109

110

Monitor Function of Remote Controller Switch

111

Group control operation

112

Setup at Local Site / Oth ers

TCC-LINK Adapter For TCC-LINK Central Control

C. Board Switch SW01 Setup

Wiring Specifications

113

Size

114

How to set up central control address number

Address setup procedure

Address Setup

Item code Data at sh ipment Setup data range

115

Sy stem configuration

Address Setup & Group Control

Only turning on source power supply Automatic completion

Automatic address example from unset address No miscabling

117

Manual setting from remote controller

END

Procedure

Procedure Push On / OFF button if th e unit stops

118

To k now th e position of indoor unit body by address

119

No. Part name Procedure Remarks

Detachment

Attachment

120

121

122

CN102 TCJ sensor 2P Red CN333 Power supply of fan motor

† Fan motor 1. Detachment

Remove nuts fixing the fan motor to Remove it

‡ Drain pan 1. Detachment

123

Body 1 position, and then remove Assembly. Ø4 × 8, 3 pcs

Assembly Perform works of items 1 of , 1 of ‚

Fix the drain pump assembly as before

124

Heat

Part name Procedure Remarks

125

RAV-SM562UT-E

Replacement of Distributor Assembly

126

RAV-SM802UT-E

127

128

129

130

131

132

Motor Remove the connector of the fan

„ Multi blade fan Remove the suction grille

Case side. Then fans come off

133

Heat exchanger support

134

135

136

Procedure Remarks

137

138

Take off fixed screw for the valve mounting

139

By hands so that the fan motor does not

Fall Tighten the flange nut with torque 4.9Nm 50kgf/cm

140

Fan guard

141

Perform works of items 1 of , and ‚

With minus screwdriver along with

Remove the upper cabinet. ST1T Ø4 × 10L, 6 pcs

142

Clamp

Fin guard Heat exchanger ST1T Ø4 × 10, 2 pcs

143

Discharge port cabinet for the heat

144

Remove the connectors by releasing lock

Relay connector

145

Terminal block 5P, Black

146

Remove the connectors by releasing lock Housing

Rectifier diode

Bottom

Loosen the flange nut by turning clock

147

Motor and the propeller fan

148

149

Product

150

151

‚ Air-outlet cabinet

152

Put the upper left side of the air-outlet

Cabinet on the end plate of heat ex

CN702 PMV Pulse Motor Valve coil

153

„ Inverter Perform the works in 1 of and ƒ

154

Remove connectors and lead wires

155

Case of RAV-SP1402AT-E

156

Case of RAV-SP1102AT-E

‰ PMV coil

157

Pay attention that 4-way valve or PMV is

158

Reactor Perform works of items to „

159

Electric parts box as shown below so that

They do not come to contact with the reac Tor

225

209 230 232

208

202

161

402 404 401 405 403

209

211 230 232 225

224

212 208 205 216, 218

163

224 201 212 208 204 216, 218 223 213, 214 228 207

211 229 231

164

232 43166006 Remotr Controller

165

RBC-U21PG W E2

304 311 306 305 301 307 302 303 310 313 308 309

166

RAV-SM562BT-E

902 36, 37, 38

43180311 Air Filter 43166002 Remotr Controller

43166004 Remotr Controller SX-A11JE2 RBC-AS21E2 43166005

43196012 Bushing 43166002 Remotr Controller

904 901, 902, 903 32, 33, 34

RAV-SM802BT-E

RAV-SM1102BT-E, RAV-SM1402BT-E

904 901, 902 34, 35, 36

170

402 404 403 406 405401407

22, 23

44, 45

36, 37, 38,39, 54

33, 34, 35,53, 56

172

404 43158193 Reactor

404401 407 403 406 402 405

173

RAVSM562AT-E RAV-SM802AT-E

174

175

705 701 702 708 707 706 710

RAV-SM1102AT-E, RAV-SM1402AT-E

176

177

707 708 706 704 703 701 705 702 710

43146695 Valve, Pulse, Modulating

21,22 16,17

178

179

704 707

180

Inverter 26,27 23,24 28,29

181

710 706 704

709

Drain up Kit

Replacement of Main Parts Sold Separately

182

TCB-DP22CE2

RBC-AX22CE2

Wireless Remote Control Kit

183

184

Required parts for installation work Recommendation

Part name ’ty Specifications/Vendor Remarks

185

Required tools for installation work

Part name Specifications Usage

186

Cord heater installation wiring diagram

187

Cord heater installation work procedure

Photo / Explanatory diagram Procedure

Assembly and the sound insulation board

Remove the motor base assembly, partition plate

188

Remove the fixing screws of the heat exchanger

189

190

191

Photo / Explanatory diagram Procedure Assembly

Material SGCC-Z08, Thickness 0.8t

Drawing of thermostat fixing plate

192

Ø3.4 burring hole Upward Ø3.4 burring hole Downward

Appendix

RAV-SP562AT-E, RAV-SP802AT-E, RAV-SP1102AT-E, RAV-SP1402AT-E

Check of Concentration Limit

Toshiba Carrier Corporation