OUTDOOR UNIT <DIGITAL INVERTER>

INDOOR UNIT <DIGITAL INVERTER>

FILE NO. A07-009

SERVICE MANUAL

CONTENTS

SAFETY CAUTION

SPECIFICATIONS

WIRING DIAGRAM

6. REFRIGERANT R410A

7. INDOOR CONTROL CIRCUIT

DANGER

Explanation of indications

Explanation of illustrated marks

Confirmation of warning label on the main unit

– 5 –

– 6 –

1. Safety Caution Concerned to New Refrigerant

2.Cautions on Installation/Service

• New Refrigerant R410A

3.Pipe Materials

4.Tools

General tools Conventional tools can be used

1. SPECIFICATIONS

1-1.Indoor Unit

– 9 –

1-1-1.High Static Duct Type <Single type>

– 10 –

Indoor unit

SM1604UT-E

Outdoor unit

<Twin type>

<Triple

– 12 –

type>

– 13 –

1-1-3.Concealed Duct Type <Twin type>

<Triple

type>

– 15 –

1-1-4.Under Ceiling Type <Twin type>

<Triple

– 16 –

type>

1-1-5.High Wall Type Twin type

<Triple

– 18 –

type>

Triple

1-1-6.Compact 4-wayCassette 600 × 600 Type

type

1-1-7.Slim Duct Type

– 20 –

<Triple

type>

– 21 –

1-2.Outdoor Unit

RAV-SM1603ATZZG-E

1-3.Operation Characteristic Curve

• Operation characteristic curve

– 22 –

RAV-SM1603AT-E, RAV-SM1603ATZ-E, RAV-SM1603ATZG-E

2. CONSTRUCTION VIEWS EXTERNAL VIEWS

2-1.Indoor Unit

Service work space

– 23 –

SM1603ATZ-E

Outdoor Unit

SM1603AT-E,RAV

– 25 –

RBC-TWP30E2, RBC-TWP50E2Simultaneous Twin

<Gas side>

RBC-TRP100ESimultaneous Triple

Gas side socket

Liquid side socket

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

3-1.Indoor Unit

Dimension table

Capillary tube specifications

•Single type

Systematic Diagram of Refrigerating Cycle

3-2.Outdoor Unit

– 29 –

RAV-SM1603AT-E, RAV-SM1603ATZ-E, RAV-SM1603ATZG-E

4. WIRING DIAGRAM

4-1.Indoor Unit

– 30 –

RAV-SM1403DT-A, RAV-SM1603DT-A

• Single type

• Twin type

• Triple type

– 31 –

– 32 –

4-2.Outdoor Unit

RAV-SM1603AT-E, RAV-SM1603ATZ-E, RAV-SM1603ATZG-E

4-3.Fan Characteristics

REQUIREMENT

nWire connection change of fan motor

– 33 –

5. SPECIFICATIONS OF ELECTRICAL PARTS

5-1.Indoor Unit

5-2.Outdoor Unit

– 34 –

6-1.Safety During Installation/Servicing

6-2.Refrigerant Piping Installation

6. REFRIGERANT R410A

6-2-1.Piping Materials and Joints Used

6-2-2.Processing of Piping Materials

– 36 –

Table 6-2-1Thicknesses of annealed copper pipes

Thickness mm

Fig. 6-2-1Flare processing dimensions

Flare and flare nut dimensions for R410A

Flare and flare nut dimensions for R22

Table

– 38 –

Nominal

Outer diameter

Tightening torque

6-3.Tools

6-4.Recharging of Refrigerant

Fig. 6-4-1Configuration of refrigerant charging

6-3-1.Required Tools

6-5.Brazing of Pipes

6-5-2.Flux 1.Reason why flux is necessary

6-5-1.Materials for Brazing

1.Silver brazing filler

2.Characteristics required for flux

3.Types of flux

6-5-3.Brazing

1.Brazing method to prevent oxidation

6-6.Instructions for Re-usePiping of R22 or R407C

6-6-4.Curing of Pipes

Page

Cautions for using existing pipe

6-6-6.Handling of Existing Pipe

– 44 –

RAV-SP1404AT-E, RAV-SP1404ATZ-E, RAV-SP1404ATZG-E

6-6-7.Recovery Method of Refrigerant

Procedure

Procedure

DANGER

6-7.Tolerance of Pipe Length and Pipe Head

n Twin system

Indoor unit A Indoor unit B

Outdoor unit

n Triple system

– 47 –

Indoor unit A

Indoor unit C

6-8.Additional Refrigerant Amount

nTwin system

– 48 –

Indoor unit A Indoor unit B

nTriple system

– 49 –

Indoor unit A

Indoor unit C

6-9.Piping Materials and Sizes

nTwin system

nTriple system

– 50 –

OKOK

NO GOOG

6-10.Branch Pipe

6-11.Distributor

7-1.Indoor Controller Block Diagram

7-1-1.Connection of Main Sub Remote Controller

7. INDOOR CONTROL CIRCUIT

– 52 –

7-2.Control Specifications

Outline of specifications

– 53 –

Item

Outline of specifications

– 54 –

Item

Remarks

Outline of specifications

– 55 –

Item

Remarks

Outline of specifications

K 2 J

– 56 –

Remarks

Outline of specifications

Setup at shipment

– 57 –

Item

– 58 –

Outline of specifications

Item

– 59 –

∗This option is not provided to oversea models

7-4.Indoor Print Circuit Board

– 60 –

<MCC-1403>

RAV-SM1403DT-A, RAV-SM1603DT-A

7-5.Outdoor Print Circuit Board

– 62 –

Noise filter P.C. board <MCC-1551>

– 63 –

<MCC-1531>

8-1.Outdoor Controls

REQUIREMENT

8-1-1.Outline of Main Controls

1.Pulse Motor Valve PMV control

4. Outdoor fan control

Operation with WE

– 65 –

Allocations of fan tap revolutions rpm

REQUIREMENT

5.Coil heating control

– 66 –

In trouble of TO sensor

6.Short intermittent operation preventive control

7.High pressure restraint TE control

8.Over-currentprotective control

9.Current release value shift control

10. Defrost control

Start of heating operation

9. INDOOR UNIT TROUBLESHOOTING

9-1.Summary of Troubleshooting

1. Before troubleshooting

2. Troubleshooting procedure

9-2.Troubleshooting

9-2-1.Check Code List Indoor

Error mode detected by indoor unit

– 71 –

– 72 –

Check code E01 error

E09 error

E10 error

E04 error

– 74 –

E18 error

E08, L03, L07, L08 error

L09 error

– 75 –

L20 error

L30 error

P30 error Central controller

– 76 –

F10 error

P10 error

– 77 –

Exchange to cooling cycle

P19 error

Exchange to heating cycle

F01 error

F02 error

– 79 –

C06 error TCC-LINKcentral controller

– 80 –

E03 error Master indoor unit

F29 error

P31 error Follower indoor unit

– 81 –

Temperature sensor

TA, TC, TCJ, TE, TS, TO sensors

TD, TL sensors

TA, TC, TCJ, TE, TS, TO sensors

10. OUTDOOR UNIT TROUBLESHOOTING

10-1.Summary of Troubleshooting

1. Before troubleshooting

2. Troubleshooting procedure

2.Troubleshooting procedure

1. Before troubleshooting

<Wireless remote controller type>

– 84 –

10-2-1.Outline of Judgment

10-2.Troubleshooting

– 85 –

Check code

Lamp indication

Cause of trouble occurrence

New Check Code

<Display on wired remote controller>

<Display on wireless sensor>

10-2-2.Others Other than Check Code

10-2-3.Check Code List Outdoor

– 88 –

– 89 –

Error mode detected by indoor unit

– 90 –

Operation. of diagnostic function

– 91 –

Judgment and measures

Cause of operation

Error mode detected by outdoor unit

– 92 –

– 93 –

Page

E09 error

Check code E01 error

– 95 –

E04 error

– 96 –

E10 error

E18 error

E08, L03, L07, L08 error

– 97 –

L09 error

L20 error

L30 error

– 98 –

b7 error Central controller

P01 error

F10 error

P10 error

– 100 –

P12 error

– 101 –

P22 error

CN301, ∗ CN303 CN300

– 102 –

RAV-SM160AT-E

F02 error

P19 error

103

P26 error

F01 error

– 104 –

P29 error

F06 error

P04 error

105

F08 error

L29 error

H02 error

– 106 –

H01 error

P03 error

– 107 –

P04 error

– 108 –

97 error Central controller

– 109 –

E03 error Master indoor unit

F29 error / 12 error

P31 error Sub indoor unit

– 110 –

– 111 –

TA sensor

TC, TCJ sensor

Caracteristics-1

Page

– 113 –

1 Setting data read out from EEPROM

CODE No. required at least

3 Writing the setting data to EEPROM

3 6 5

– 114 –

Step

115

Table

Table 2. Type: CODE No.

Table 3. Indoor unit capacity: CODE No.

12. SETUP AT LOCAL SITE AND OTHERS

12-1.Indoor Unit

12-1-1.Test Run Setup on Remote Controller

<Wired remote controller>

3 6 1

4 5 2

1 2 3 4 5 6 END

1.D02 Red

Contents

118

Function selection item No. DN list

At shipment from factory

Setup method

Wired remote controller

– 119 –

Operation

2 4 1

<Contents>

<Procedure>

call the service monitor mode

nCalling of error history

<Contents>

Procedure

4 seconds or more to call the service check mode

nIndoor unit power-ONsequence

which receives power feed from outdoor unit>

<Automatic address judgment>

<By indoor unit

12-2.Setup at Local Site / Others

2. Microprocessor block diagram

3. TCC-LINKwiring connection

1. Function

5. P.C. board switch SW01 setup

4. Wiring specifications

– 124 –

6. External view of P.C. board assembly

7. Address setup

12-3.How to Set up Central Control Address Number

1 2 3 4

– 126 –

Push UNIT LOUVER button for 4 seconds or more

13-1.Address Setup Procedure

13. ADDRESS SETUP

– 127 –

13-2.Address Setup & Group Control

13-2-1.System Configuration

– 128 –

<Terminology>

– 129 –

Example

Change is necessary

3, 6, 9 4

2, 5,

1 2 3 4 5 6 7 8 9 10 11 END

1 2 END

1 2 3 END

nConfirmation of indoor unit No. position

<Procedure>

2. How to replace the parts

14. DETACHMENTS

14-1.Indoor Unit REQUIREMENT

Work procedure

2. How to replace the parts Continued

Work procedure

– 134 –

Explanatory drawing

Work procedure

2. How to replace the parts Continued

– 135 –

4. How to replace the parts

Work procedure

REQUIREMENT

– 136 –

4. How to replace the parts Continued

Work procedure

– 137 –

Explanatory drawing

5.Assembling work after replacing fan motor

4. How to replace the parts Continued

Work procedure

– 138 –

Work procedure

6. How to replace the sensor

– 139 –

6. How to replace the sensor Continued

7. How to clean the drain port

Work procedure

Work procedure

14-2.Outdoor Unit

– 141 –

XREQUIREMENTX

XREQUIREMENTX

Procedure

– 142 –

Part name

CDB board

– 143 –

144

XCAUTIONX

– 145 –

XREQUIREMENTX

– 146 –

XREQUIREMENTX

– 147 –

XWARNINGX

X CAUTIONX

X CAUTIONX

– 148 –

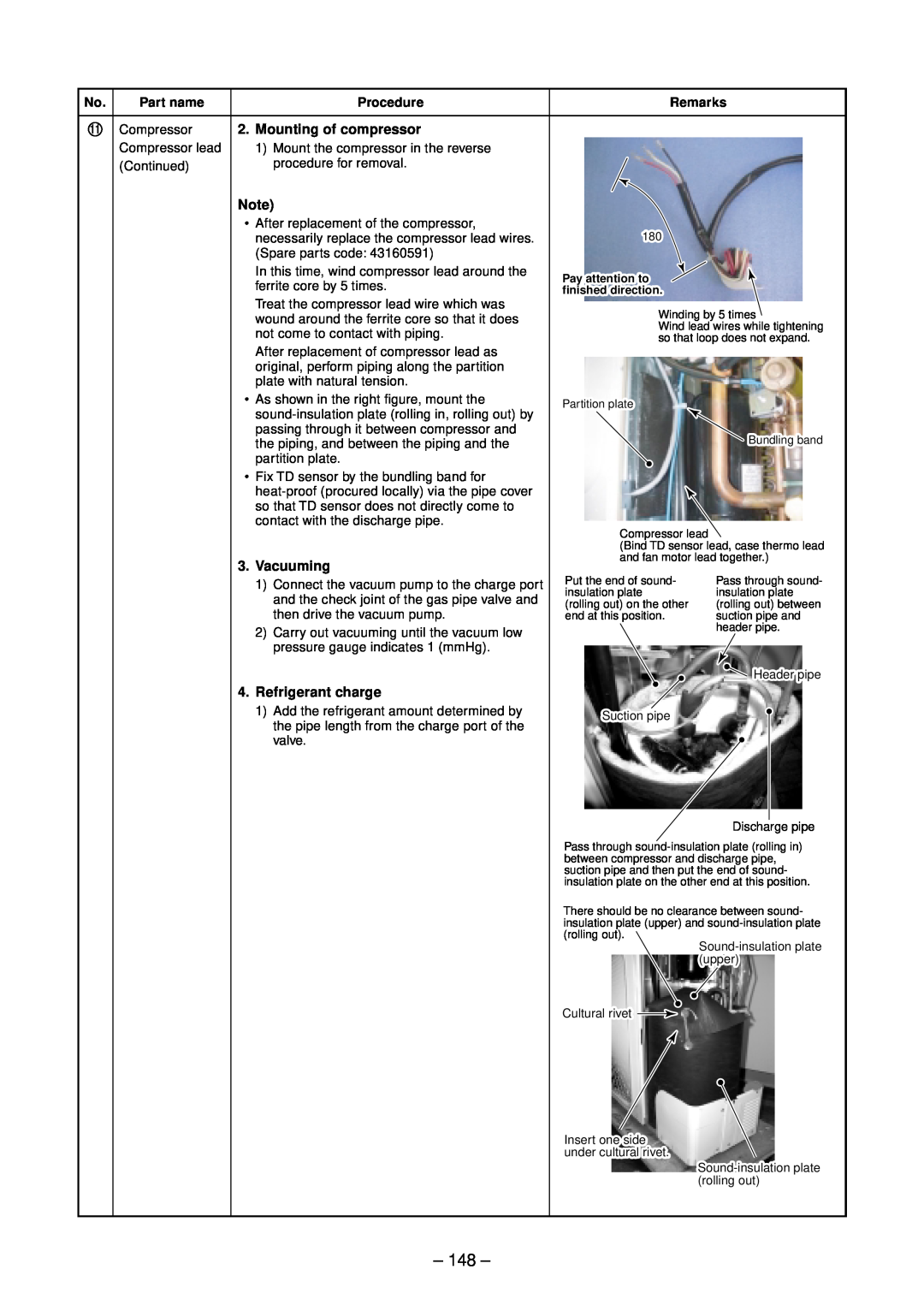

2. Mounting of compressor

3. Vacuuming

4. Refrigerant charge

149

XREQUIREMENTX

XREQUIREMENTX

1. Detachment

15. EXPLODED VIEWS AND PARTS LIST

15-1

Indoor Unit

– 150 –

151

Location

Part No

Description

– 152 –

RAV-SM1403DT-A, RAV-SM1603DT-A

Location

Part No

15-2.Outdoor Unit

154

Location

Description

Model Name

716,

WARNINGS ON REFRIGERANT LEAKAGE

Check of Concentration Limit

TOSHIBA CARRIER CORPORATION