Troubleshooting

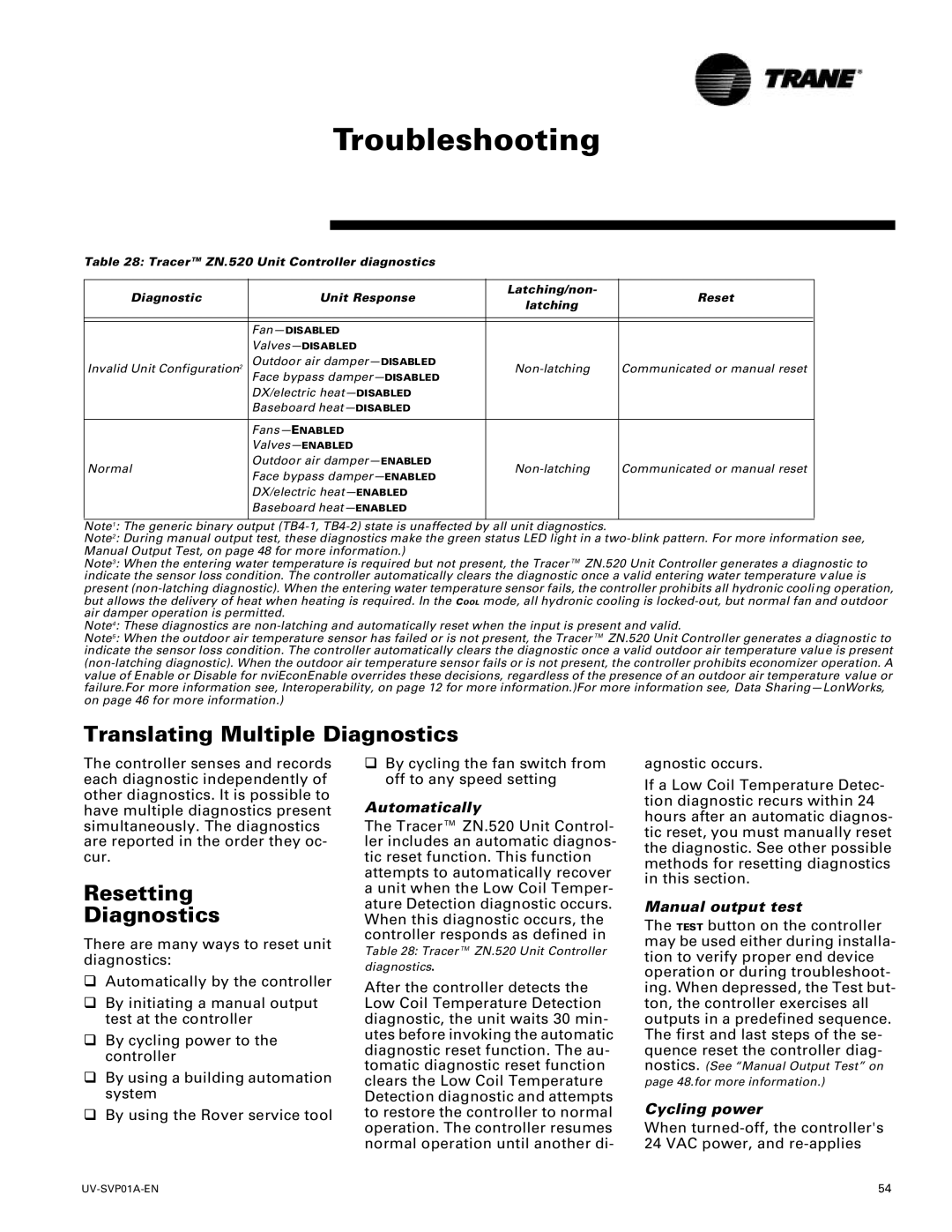

Table 28: Tracer™ ZN.520 Unit Controller diagnostics

Diagnostic | Unit Response | Latching/non- | Reset | |

latching | ||||

|

|

| ||

|

|

|

| |

|

|

|

| |

|

|

| ||

|

|

| ||

Invalid Unit Configuration2 | Outdoor air | Communicated or manual reset | ||

Face bypass | ||||

|

|

| ||

| DX/electric |

|

| |

| Baseboard |

|

| |

|

|

|

| |

|

|

| ||

|

|

| ||

Normal | Outdoor air | Communicated or manual reset | ||

Face bypass | ||||

|

|

| ||

| DX/electric |

|

| |

| Baseboard |

|

| |

|

|

|

|

Note1: The generic binary output

Note2: During manual output test, these diagnostics make the green status LED light in a

Note3: When the entering water temperature is required but not present, the Tracer™ ZN.520 Unit Controller generates a diagnostic to indicate the sensor loss condition. The controller automatically clears the diagnostic once a valid entering water temperature value is present

Note4: These diagnostics are

Note5: When the outdoor air temperature sensor has failed or is not present, the Tracer™ ZN.520 Unit Controller generates a diagnostic to indicate the sensor loss condition. The controller automatically clears the diagnostic once a valid outdoor air temperature value is present

Translating Multiple Diagnostics

The controller senses and records each diagnostic independently of other diagnostics. It is possible to have multiple diagnostics present simultaneously. The diagnostics are reported in the order they oc- cur.

Resetting

Diagnostics

There are many ways to reset unit diagnostics:

qBy cycling the fan switch from off to any speed setting

Automatically

The Tracer™ ZN.520 Unit Control- ler includes an automatic diagnos- tic reset function. This function attempts to automatically recover a unit when the Low Coil Temper- ature Detection diagnostic occurs. When this diagnostic occurs, the controller responds as defined in

Table 28: Tracer™ ZN.520 Unit Controller

diagnostics.

agnostic occurs.

If a Low Coil Temperature Detec- tion diagnostic recurs within 24 hours after an automatic diagnos- tic reset, you must manually reset the diagnostic. See other possible methods for resetting diagnostics in this section.

Manual output test

The TEST button on the controller may be used either during installa- tion to verify proper end device operation or during troubleshoot-

qAutomatically by the controller

qBy initiating a manual output test at the controller

qBy cycling power to the controller

qBy using a building automation system

qBy using the Rover service tool

After the controller detects the Low Coil Temperature Detection diagnostic, the unit waits 30 min- utes before invoking the automatic diagnostic reset function. The au- tomatic diagnostic reset function clears the Low Coil Temperature Detection diagnostic and attempts to restore the controller to normal operation. The controller resumes normal operation until another di-

ing. When depressed, the Test but- ton, the controller exercises all outputs in a predefined sequence. The first and last steps of the se- quence reset the controller diag- nostics. (See “Manual Output Test” on

page 48.for more information.)

Cycling power

When

54 |