Unit Operation

seconds. This provides the ample torque required to start all fan mo- tors from the off position.

Exhaust fan/damper operation

This binary point is a shared point with medium fan speed. For this point to be used for exhaust con- trol, the controller must be config- ured for a 1- or 2-speed fan. The exhaust fan/damper is coordinated with the unit fan and outdoor damper operation. The exhaust output is energized only when the unit fan is operating and the out- door damper position is greater than or equal to the configurable exhaust enable point. The exhaust fan output is disabled when the outdoor air damper position drops 10% below the exhaust enable point. If the enable point is less than 10%, the unit turns on at the enable point and off at 0.

Valve Operation

Modulating Valves

The Tracer ZN.520 controller sup- ports one or two modulating valves for hydronic heating and cooling operation. The main valve/ coil is used for cooling only, heat/ cool changeover (2-pipe applica- tions), or cooling (4-pipe applica- tions). The auxiliary valve/coil provides heating in 4-pipe and heating only applications.

At power-up, the Tracer ZN.520 controller drives the modulating valves to the closed position. The controller calibrates to the full closed position by overdriving the actuator 135%. Whenever the con- troller requests a valve position of zero or 100%, the controller over- drives the actuator 135% regard- less of the current valve position.

Face-and-Bypass

Isolation Valves

Face-and-bypass units may use isolation valves to prevent unwant- ed water flow in the coil. This elim- inates problems such as radiant heat or excessive condensate in 2- pipe systems.

In 4-pipe applications, the isolation valves are used to prevent conflict- ing capacities within the unit.

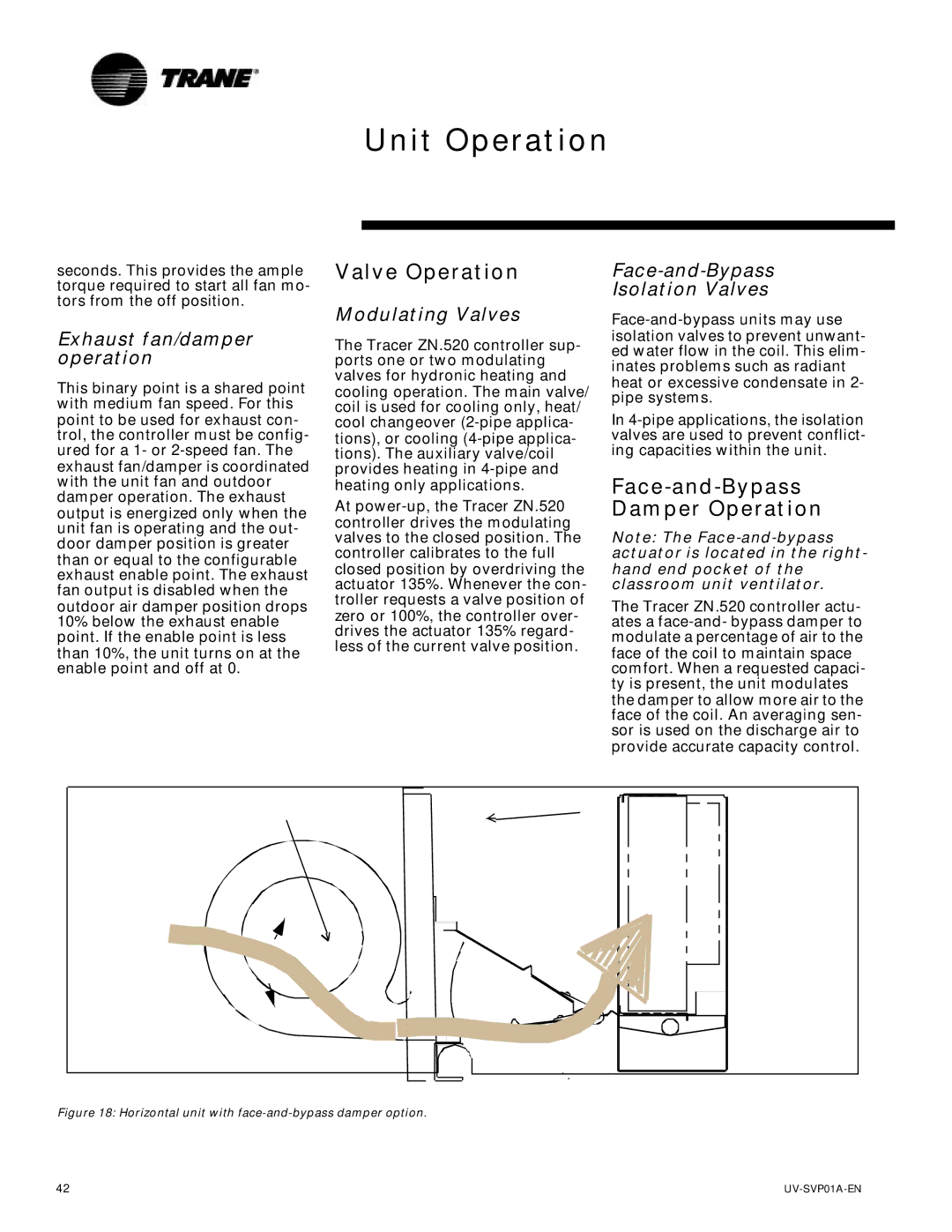

Face-and-Bypass Damper Operation

Note: The Face-and-bypass actuator is located in the right- hand end pocket of the classroom unit ventilator.

The Tracer ZN.520 controller actu- ates a face-and- bypass damper to modulate a percentage of air to the face of the coil to maintain space comfort. When a requested capaci- ty is present, the unit modulates the damper to allow more air to the face of the coil. An averaging sen- sor is used on the discharge air to provide accurate capacity control.

Figure 18: Horizontal unit with face-and-bypass damper option.