YFM400FAR

YFM400FAR

Important Information

Exploded Diagrams

Manual Organization

GEN Spec Info CHK ENG ADJ

Table of Contents

Contents Chapter General Information

Seat and Side Panels

Introduction

Fuel Tank

Chapter Engine

Page

Chapter Cooling System

Troubleshooting

Rear AXLE/FINAL Drive Gear and Drive Shaft

Chapter Chassis

Chapter Electrical

Front Arms and Front Shock Absorbers

Faulty Clutch Performance

Faulty Drive Train

Faulty Gear Shifting

Starting FAILURE/HARD Starting

Poor Braking Effect

Faulty Brake

Overheating

Malfunction

Vehicle Identification Number

Model Label

Replacement Parts

Preparation for Removal Procedures

GASKETS, OIL Seals and O-RINGS

Bearings and OIL Seals

Lock WASHERS/PLATES and Cotter Pins

Circlips

Checking of Connections

Tool No Tool name/How to use Illustration

Crankshaft installer set

Sheave fixed block

Compression gauge

Clutch holding tool

General Specifications

DR8EA/NGK

Mikuni

Maxxis

YTX14AH

Engine

Seat Width Margin Thickness Head Diameter Face Width

41.27 mm

Spec

Spec

Spec

Pressure feed Splashed scavenge Camshaft Crank Pin

Standard Limit Cylinder head tightening sequence

Tightening torques

Neutral switch M10 Reverse switch Stator assembly

Chassis

DOT

Tightening torques

Spec

Electrical

4BA/DENSO

MS5F-561/JIDECO

5ND/NIPPON Thermostat

Metric Multiplier Imperial

Conversion Table

Lubrication Points and Lubricant Types

Coolant Flow Diagrams

Radiator Thermostat To coolant reservoir

OIL Flow Diagrams

Oil filter

Oil pump Oil strainer

Cable Routing

Spec

Spec

Spec

Spec

Spec

Spec

Spec

Spec

Spec

Introduction

CHK ADJ

Seat and Side Panels

Removing the seat and side panels

Removing the front carrier, front

Front CARRIER, Front Bumper and Front Fender

Bumper and front fender

CHK ADJ

Fender

Rear Carrier and Rear Fender

Removing the rear carrier and rear

First disconnect the negative lead

CHK ADJ

Removing the fuel tank

Fuel Tank

Bumper and Front Fender

Removing the footrest boards

Adjusting the Valve Clearance

Adjusting the Valve Clearance

Tappet adjusting tool YM-08035

Adjustment steps

Locknut 20 Nm 2.0 m kg, 14 ft lb

Adjusting the Idling Speed

Engine idling speed 1,450 ~ 1,550 r/min

Turning Idling speed becomes Higher Turning out Lower

Adjusting the Throttle Lever Free Play

Throttle lever free play ~ 5 mm 0.12 ~ 0.20

Adjustment steps First step

Second step

Adjusting the Speed Limiter

Speed limiter length 12 mm 0.47

Speed limiter length adjustment steps

Adjusting the Starter Cable

Starter plunger stroke distance 15 mm 0.59

Standard spark plug DR8EA/NGK

Checking the Spark Plug

Spark plug gap ~ 0.7 mm 0.024 ~ 0.028

Recoil starter bolt 10 Nm 1.0 m kg, 7.2 ft Ib

Checking the Ignition Timing

Engine speed 1,450 ~ 1,550 r/min

Loctite

Measuring the Compression Pressure

Compression gauge YU-33223 Adapter YU-33223-3

Measuring the Compression Pressure

Checking the Engine OIL Level

Recommended oil Follow the left chart

Do not allow foreign material to enter the crankcase

Changing the Engine OIL

Replacement steps

Oil filter wrench YU-38411

Cautio N

Oil filter cartridge 17 Nm 1.7 m kg, 12 ft lb

Cleaning the AIR Filter

Oil gallery bolt Nm 0.7 m kg, 5.1 ft lb

Cleaning the AIR Filter

Cleaning steps

Checking the Coolant Level

Changing the Coolant

10 Nm 1.0 m kg, 7.2 ft lb

CHK ADJ

Checking the V-BELT

Checking the Coolant Temperature

Belt width 30.7 mm 1.21 in Limit 27.6 mm 1.09

Replacing steps

Cleaning the Spark Arrester

Rear brake pedal free play 20 ~ 30 mm 0.80 ~ 1.18

Adjusting the Rear Brake

Rear brake pedal free play 20 ~ 30 mm 0.8 ~ 1.2

Gap a ~ 1 mm 0.00 ~ 0.04

Recommended brake fluid

Checking the Front Brake Fluid Level

DOT

Brake pad wear limit a 1 mm 0.04

Checking the Front Brake Pads

Checking the Rear Brake Shoes

Checking the Brake Hoses

Air bleeding steps

Bleeding the Hydraulic Brake System

Bleed screw Nm 0.6 m kg, 4.3 ft lb

Adjusting the Select Lever Control Cable and Shift ROD

Adjustment steps Control cable

Adjusting the Rear Brake Light Switch

Select lever shift rod

Checking the Final Gear OIL Level

Direction a Brake light comes on Sooner Direction b Later

Recommended oil SAE 80 API GL-4 Hypoid gear oil

Changing the Final Gear OIL

Checking the Constant Velocity Joint Dust Boots

Changing the Differential Gear OIL

Adjusting the TOE-IN

Checking the Steering System

Toe-in = É È

Locknut rod end 40 Nm 4.0 m kg, 29 ft lb

Adjusting the Rear Shock Absorber

Adjusting the Front Shock Absorbers

Checking the Tires

Maxxis

Tire Characteristics

Manufacturer Size Type

Maximum Loading Limit

Cold tire Front Rear

Checking the Wheels

Checking and Lubricating the Cables

Lubricating the LEVERS, PEDAL, ETC

Recommended lubricant Lithium soap base grease

Checking the Battery

Charging Method

Battery condition checking steps

Keep Batteries and Electrolyte OUT of Reach of Children

Or higher No charging is Necessary

Open-circuit Charging time

Example

Charging method using a variable voltage charger

YES

Charging method using a constant voltage charger

Checking the Fuses

Description

Pocket tester YU-03112-C

Quantity

Adjusting the Headlight Beams

Changing the Headlight Bulb

Changing the Headlight Bulb

Removing the air ducts, muffler

AIR DUCTS, Muffler and Exhaust Pipe

Exhaust pipe

ENG

Removing the select lever unit

Select Lever Unit and Coolant Reservoir

Coolant reservoir

Hoses and Leads

Removing the hoses and leads

Engine Mounting Bolts

Install all of the bolts/nuts and then

Specifications

Tighten Them to full torque

ENG

Installing the Engine

Removing the cylinder head

Cylinder Head

Removing the Cylinder Head

Rotor holding tool YU-01235

Checking the Timing Chain Tensioner

Checking the Tappet Covers

Checking the Camshaft Sprocket

ENG

Installing the Cylinder Head

Installing steps

Installation steps

Cap bolt timing chain tensioner 23 Nm 2.3 m kg, 17 ft lb

Tighten Camshaft sprocket bolt

Camshaft and Rocker Arms

Removing the camshaft, rocker

Arms and valves

Valves and Valve Springs

ENG

Removing the Camshaft and Rocker Arms

Slide hammer set YU-01083-A Slide hammer bolt M6 Weight

Removing the Valves and Valve Springs

Checking the Camshaft

Valve spring compressor YM-04019

Checking the Rocker Arms and Camshaft

Check Rocker arms Rocker arm shafts Damage/wear → Replace

Checking the Valves and Valve Springs

Runout limit 01 mm 0.0004

U T ION

Lapping steps

Installed length

Installing the Valves and Valve Springs

Spring tilt limit Inner 1.6 mm 0.06 in Outer

Installing the Camshaft and Rocker Arms

Removing the cylinder and piston

Piston

Do not use a hammer to drive the piston pin out

Removing the Piston

Piston pin puller set YU-01304

Checking the Timing Chain Guide

05 mm

Measurement steps 1st step

Cylinder bore C 84.500 ~ 84.510 mm 3268 ~ 3.3272

0016

Side clearance

3rd step

Checking the Piston Rings

Standard Limit Top 03 ~ 0.08 mm 13 mm Ring

2nd ~ 0.60 mm 95 mm Ring

End gap Standard Limit

~ 0.40 mm 65 mm Ring

~ 0.7 mm Ring

Installing the Piston

Installing the Cylinder

Chapter

Removing the A.C. magneto

Magneto

ENG

Assembling the Recoil

Disassembling the recoil starter

Starter

Disassembling the Recoil Starter

Removing the A.C. Magneto

Flywheel puller YM-01404

Checking the A.C. Magneto

Checking the Starter Clutch

Bolts starter clutch 30 Nm 3.0 m kg, 22 ft lb

Checking the Recoil Starter

Checking the Starter Pulley

Assembling the Recoil Starter

Installing the A.C. Magneto

Sealant Quick Gasket ACC-11001-05-01 Yamaha bond No

Use a rotor holding tool 2 to hold the starter pulley

Primary and Secondary

Removing the primary

Secondary sheaves

Sheaves

For installation, reverse the removal

Sheave

Primary Sliding Sheave

Disassembling the primary sliding

Sheave

Disassembling the secondary

Secondary Sheave

Assembling the Secondary

Disassembling the Secondary Sheave

Removing the Primary Secondary Sheaves

Sheave holder YS-01880-A

Removing steps

Checking the Secondary Sheave

Weight outside diameter 30 mm 1.18 Limit 29.5 mm 1.16

Checking the Primary Sheave

Free length 121.4 mm 4.78 Limit 115.33 mm 4.54

Assembling the Primary Sheave

Assembling the Secondary Sheave

Nut 90 Nm 9.0 m kg, 65 ft lb

Installing the Primary and Secondary Sheaves

Removing the clutch

Clutch

Disassembling the clutch housing

Clutch holding tool YM-91042

Removing the Clutch

Checking the Clutch

Installing the Clutch

Install Dowel pins Gasket New Clutch housing assembly

Chain and oil filter

Starter MOTOR, Timing Chain and OIL Filter

Removing the starter motor, timing

OIL Pump Drive Gear

ENG

Separating the crankcase

Crankcase

Lever

Removing the crankcase bearings

Crankcase Bearings

Pump

Separating the Crankcase

Removing the OIL Pump Drive Gear

Removal steps

Separation steps

Checking the Timing Chain and Guide

Checking the OIL Strainer and OIL Delivery Pipe

Checking the Bearings

Checking the Crankcase

Assembling the Crankcase

Installing the Shift Lever

Installing the OIL Pump Drive Gear

Tightening steps

Pump

CRANKSHAFT/INSTALLING

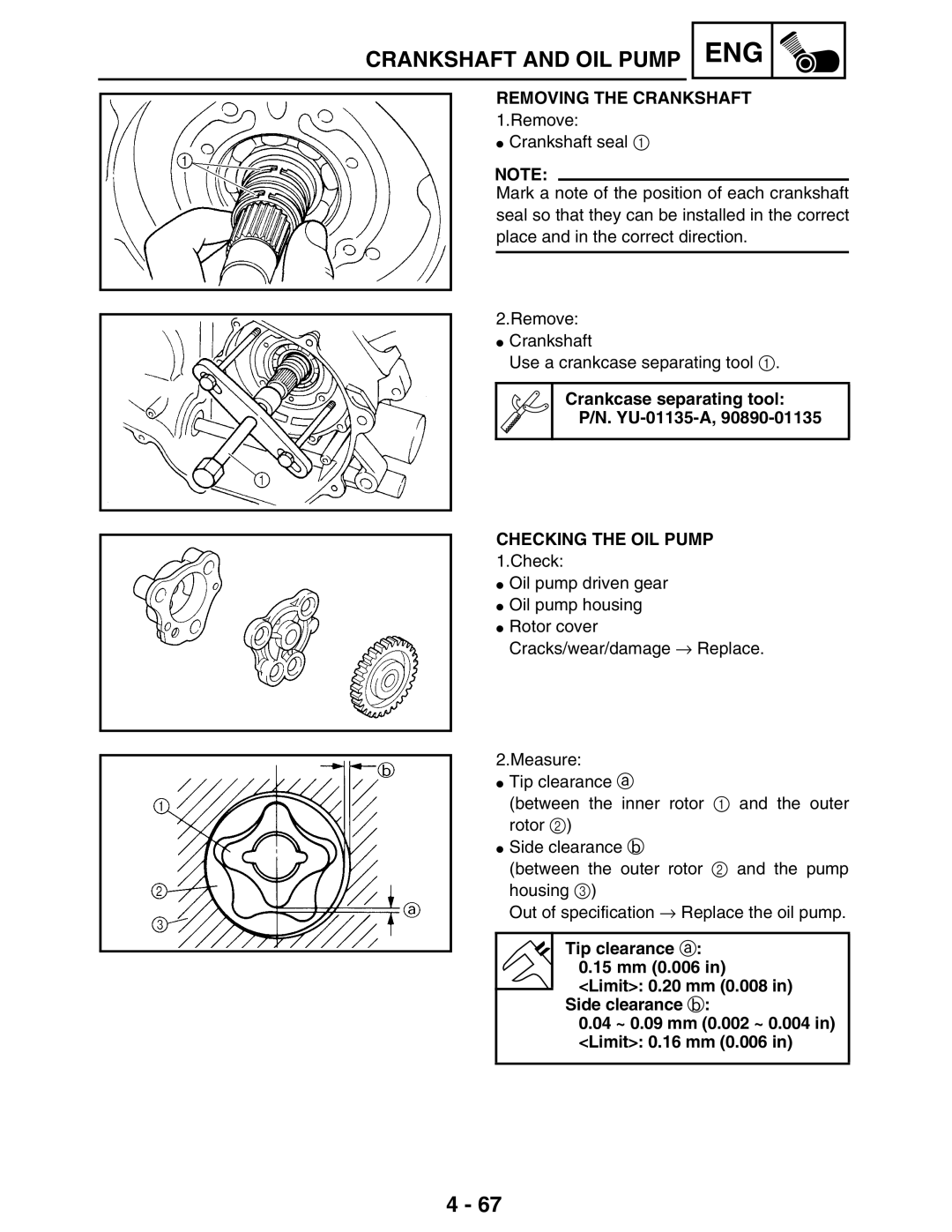

Removing the crankshaft and oil

Crankshaft and Balancer

OIL Pump

Disassembling the oil pump

Crankcase separating tool YU-01135-A

Removing the Crankshaft

Checking the OIL Pump

Checking the Crankshaft

Crank width 62.95 ~ 63.00 mm 2.4783 ~ 2.4803

Installing the Crankshaft and Balancer

Removing the transmission

ENG

Checking the Shift CAM

Checking the Shift Forks

Do not attempt to straighten a bent guide bar

Checking the Transmission

Checking the Secondary Shaft and Driven Sprocket

Checking the Chain

Installing the Transmission

Removing the middle drive shaft

Middle Drive Shaft

Drive and Driven Gear Shims

Middle Driven Shaft

Removing the middle driven shaft

ENG

Removing the Middle Drive Shaft

Removing the Middle Driven Shaft

Universal joint holder YM-04062

Bearing retainer wrench YM-04128

Ring nut wrench YM-38404

Checking the Pinion Gears

Selection steps

Selecting the Middle Drive and Driven Gear Shims

Middle drive pinion gear shim thickness a = c a b

Middle drive pinion gear shim Thickness mm

Hundredths Round value 5, 6

Middle driven pinion gear shim Thickness = d e + f g

ENG

Installing the Middle Driven Shaft

Tighten the bearing retainer

Middle gear lash ~ 0.3 mm 0.004 ~ 0.012 Measurement steps

Installing the Middle Drive Shaft

Measuring the Middle Gear Backlash

Pinion gear fix clamp YM-04129

Gear lash measurement tool YM-01467

Cool

Removing the radiator

Cool

Checking the Radiator

Radiator cap tester YU-24460-01 Adapter YU-33984

Installing the Radiator

Removing the thermostat

Installing the Thermostat

Checking the Thermostat

Removing the water pump

Disassembling the water pump

Disassembling the Water Pump

Checking the Water Pump

Max. impeller shaft tilt 0.15 mm 0.006

Assembling the Water Pump

Cool

Removing the carburetor

Disassembling the carburetor

Carburetor

Carb

Disassembling the Carburetor

Checking the Carburetor

Carb

Float height F.H mm 0.51 Measurement and adjustment steps

Assembling the Carburetor

Adjusting the Fuel Level

Fuel level gauge YM-01312-A

Driv

Following noises may indicate a mechanical defect

Troubleshooting Driv

Troubleshooting chart

YES

Removing the front constant

Velocity joints and differential gear

Driv

Joints

Disassembling the constant velocity

Constant Velocity Joints

Differential gear

Driv

Always use new boot bands

Removing the Differential Gear Assembly

Checking the Constant Velocity Joints

Checking the Differential Gear

Molybdenum disulfide grease 40 g 1.4 oz per dust boot

Assembling the Front Constant Velocity Joints

Assembling the Differential Gear

Gear lash measurement tool YM-01475

Differential gear lash 10 ~ 0.50 mm 0.004 ~ 0.020

Increase shim

Adjusting differential gear lash

Reduce shim

Ring gear shim left and right Thickness mm

Checking the Differential Gear Operation

Removing the rear axle, final drive

Gear assembly and drive shaft

Installing

Rear Axle

Disassembling the final drive gear

Gear

Assembling the Final Drive

Drive Roller Bearings

Removing the Rear Axle

Disassembling the Final Drive Gear

Replacing the Final Drive Roller Bearings

Final drive pinion gear shim thickness a = a b

Positioning the Final Drive Pinion Gear and Ring Gear

Final drive pinion gear shim selection

Hundredths Rounded value 5, 6

Ring gear shim thickness = c + d e + f

Bearing thickness f 11.00 mm

Measure/select Ring gear thrust clearance C

Thrust washer Thickness mm

Ring gear thrust clearance ~ 0.2 mm 0.004 ~ 0.008

Thrust washer selection steps

Ring gear stopper shim selection

Ring gear stopper clearance 0.30 ~ 0.60 mm 0.012 ~ 0.024

Ring gear stopper clearance adjustment

Shim Thickness mm

Checking the Rear Axle

Checking the Drive Shaft

Checking the Final Drive Gear

Final gear lash measurement

Measurement and Adjusting the Final Gear Lash

Final gear lash ~ 0.2 mm 0.004 ~ 0.008

Final gear lash adjustment

Ring gear shim Thickness mm 25 0.30 40 0.45 Thrust washer

Assembling the Final Drive Gear

Installing the Final Drive Gear

Lithium-soap-based grease

Sealant Quick gasket ACC-11001-05-01 Yamaha bond No.1215

Nuts Bolts

Is no danger of it falling over

Front Wheels

Removing the front wheels

Hubs

Rear Wheels

Removing the rear wheels

Checking the Wheel Hubs

Checking the Brake Discs

Installing the Wheel Hubs

Installing the Wheels

Brake disc maximum deflection 15 mm 0.006

Install Nuts wheel

Removing the front brake pads

Front Brake Pads

Brake Pads

Replacing the Front Brake Pads

Brake pad wear limit 1 mm 0.04

Brake caliper bleed screw 6 Nm 0.6 m kg, 4.3 ft lb

Cylinder

Front Brake Master Cylinder

Removing the front brake master

Brake Master Cylinder

Disassembling the front brake

Master cylinder

Checking the Master Cylinder

Assembling the Front Brake Master Cylinder

Installing the Front Brake Master Cylinder

Chas

Removing the front brake calipers

Front Brake Caliper

Calipers

Calipers

Assembling the Front Brake

Disassembling the Front Brake Calipers

Recommended brake component Replacement schedule Brake pads

Checking the Front Brake Calipers

Installing the Front Brake Calipers

Assembling the Front Brake Calipers

Fill Brake reservoir

Removing the rear brake lever

Removing the rear brake pedal

Removing the rear brake drum

Chas

Removing the Rear Brake

Checking the Rear Brake

Brake drum inside diameter limit maximum 161 mm 6.34

Installing the Rear Brake

Brake shoe lining thickness limit 2.0 mm 0.08

Lithium-soap base grease

Bolt camshaft lever Nm 0.9 m kg, 6.5 ft lb

Bolt brake shoe plate 28 Nm 2.8 m kg, 20 ft lb

Chas

Handlebar

Cylinder Assembly

Brake Switch

Removing the handlebar

Installing the Rear Brake Lever

Removing the Rear Brake Switch

Installing the Handlebar

Checking the Handlebar

Installing the Master Cylinder Assembly

Removing the steering stem

Steering Stem

Guide

Bearing Retainer

Removing the Bearing Retainer

Installing the Bearing Retainer

Installing the Cable Guide

Checking the Steering Stem

Knuckles

TIE Rods and Steering Knuckles

Removing the tie rods and steering

Knuckles

Chas

Checking the TIE Rods

Removing the Steering Knuckles

Checking the Steering Knuckles

Chas

Eye protection is recommended when using striking tools

Installing the TIE Rods

Removing the front arms and front

Shock absorbers

Arms and Front Shock

Absorber

Removing the Front Arms

Checking the Front Arms

Replacement steps

Checking the Front Shock Absorber

Nut 45 Nm 4.5 m kg, 32 ft lb

Installing the Front Arms and Front Shock Absorber

Nut 30 Nm 3.0 m kg, 22 ft lb

Removing the rear shock absorber

Swingarm

Housing

Swingarm

Nut swingarm 82 Nm 8.2 m kg, 59 ft lb

Removing the Swingarm

Checking the Rear Shock Absorber

Installing the Rubber Boot

Checking the Rubber Boot

Checking the Swingarm

Installing the Rear Axle Housing

Nut 63 Nm 6.3 m kg, 45 ft lb Loctite Bolt Loctite Nut

Electrical Components Elec

Checking a Switch Shown in the Manual

Checking a Switch

Example chart shows that

Elec +

Checking the Switch Continuity

Elec

Types of Bulbs

Checking the Condition of the Bulbs

Pocket tester YU-03112-C

Checking the Condition of the Bulb Sockets

Circuit Diagram

Open-circuit voltage Or more at 20 C 68 F

Troubleshooting

Procedure

Standard spark plug

Minimum spark gap 6.0 mm 0.24

Spark plug gap

Spark plug cap resistance 10 kΩ at 20 C 68 F

C0NTINUITY

Both Meet Specification

Correct OUT of Specification

Primary coil resistance 18 ~ 0.28 Ω at 20 C 68 F

Main switch Refer to Checking the Switches

Correct Poor Connection

Properly connect the ignition system Replace the CDI unit

System Electric Starting System Elec

If the Starter Motor Fails to Operate

Turns

Does not Turn

Incorrect Correct

Disassembling the starter motor

Starter Motor

Removing the starter motor

Motor

Outside diameter 28 mm 1.10 Wear limit 27 mm 1.06

Checking the Starter Motor

Mica undercut 0.7 mm 0.03

Brush length 12.5 mm 0.49 Wear limit 5 mm 0.20

Assembling the Starter Motor

Charging

If the Battery is not Charged

Continuity No Continuity

OUT of Specification

Meets Specification

OUT Specification

Charging voltage

Headlight fuse

If the Headlight AND/OR Taillight Fail to Come on

Correct Incorrect

Checking the Lighting System

Meets Specification No Continuity

Tester + lead → Blue lead 1 Tester lead → Black lead

Tester + lead → Blue terminal 1 Tester lead → Black terminal

Elec

Elec

Elec

EB806010

Properly connect the signal system

Checking the Signal System

If the neutral indicator light fails to come on

If the reverse indicator light fails to come on

Less than 120 ± 3 C 248 ± 5.4 F

Test Coolant temperature Thermo switch Continuity Step

235.4 F

Good Condition

BAD Condition

Correct

OUT of Specification Meets

Cooling

System

If the FAN Motor does not Move

Meets Specification Does not Turn

Circuit breaker resistance Zero Ω at 20 C 68 F

176 ± 5.4 F

Less than 86 ± 3 C 186.8 ± 5.4 F

Good

Properly connect the cooling system

System

If the Gear Motor Fails to Operate

Replace the on-command four-wheel drive switch

Correct Poor Connection

Fuel System

Electrical System

Compression System

Poor Medium and HIGH-SPEED Performance

Faulty Drive Train

Jumps OUT of Gear

Hard Shifting

Shift Lever does not Move

Engine Operates but Machine will not Move

Overheating

Poor Speed Performance

Poor Braking Effect

Headlight Dark

Malfunction

Unstable Handling

Bulb Burnt OUT

YFM400FAR Wiring Diagram

Shingai Iwata Shizuoka Japan