Split Type

Name 0BT-E ∗∗ 1BT-E

Type Indoor unit Outdoor unit

DC motor AC motor

∗∗ 1CT-E

Contents

Installation Manual

Outdoor

To Disconnect the Appliance from Main Power Supply

Precautions for Safety

New Refrigerant Air Conditioner Installation

RAV-SP1100, 1400AT-E RAV-SM1100, 1400AT-E

Accessory and Installation Parts

Accessory and Refrigerant

Refrigerant Piping

Selection of Installation

Before installation

Obstacle at rear side Upper side is free

Installation Place

Necessary Space for Installation

Obstacle at front side Upper side is free

Serial installation at front and rear sides

Installation of Outdoor Unit

Standard installation

Obstacle also at the upper side

For Reference

Optional Installation Parts Local Procure

Refrigerant Piping Connection

Knockout of Pipe Cover

Refrigerant Piping

Pipe Forming/End Positioning

Tightening of Connecting Part

Outer dia. of copper pipe Tightening torque

Air Purge

Evacuating

Vacuum pump

Valve size

How to open the valve

Charge port

How to wire

Stripping length power cord and connecting cable

Electrical Work

Check and Test Operation

Final Installation Checks

Self-Diagnosis by LED Indication

New tools for R410A

Changes in the product and components

New tools for R410A Applicable to R22 model Changes

Indoor

RAV-SM560, 561, 800, 801BT-E RAV-SM1101, 1401BT-E

Part name ’ty Shape Standard wired remote Controller

Separate sold parts

Part name ’ty Shape

Connect the connecting cable correctly

Inappropriate grounding may cause electric shock

Advice

Selection of Installation Place

Installation space Selection of installation place

Secure the space required to installation and servicing

Installation of Indoor Unit

Installation procedure

100

Dimension

External view

RAV-SM1101, 1401BT

Hanging down of indoor unit

Installation of remote controller Sold separately

Mounting of clamp Accessory

Clamp mounting Removal of air filter

Concealed duct type

Restriction to installation

Installation clearance

Ledge ceiling concealed duct type

AIR Ducting Work

Static pressure characteristics of each model

103

RAV-SM1101BT Round duct

RAV-SM1401BT Round duct

Connecting method of the duct

General cautions

Points at installation work

106

Mounting of filter and canvas for suction port

Mounting of remote controller

Hanging of indoor unit

107

Piping and cautions

Drain Piping Work

Piping material

Thermal-insulating process

Check of water drain

Drain-up

Connection of the drain hose

After electric piping work

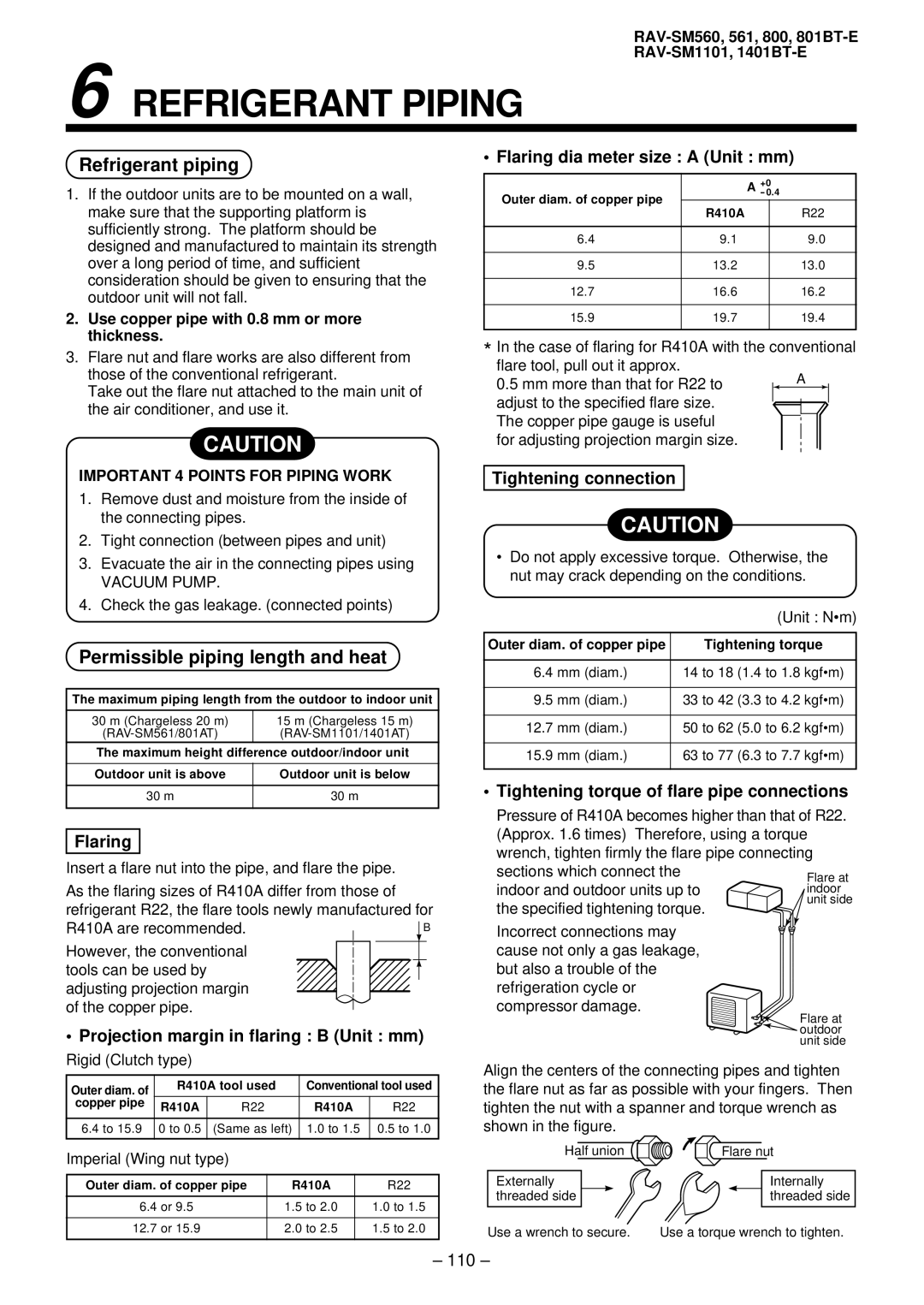

Tightening connection

Permissible piping length and heat

Flaring dia meter size a Unit mm

Tightening torque of flare pipe connections

Gas leak check

Packed valve handling precautions

Open valve fully

Use a vacuum pump

801, 1101, 1401 type valve at gas side

For 801, 1101, 1401AT model

112

113

Cabling

Remote controller cabling

Cabling diagram

114

Test RUN

How to execute a test run

Case of wired remote controller

Before test run

Procedure Description

Troubleshooting

Confirmation of error history

Confirmation and check

Automatic address

Applicable Controls

117

To incorporate a filter sold separately

Setup of external static pressure

When using wireless remote controller

Short plug position CN112, CN111, CN110 from the left

To secure better effect of heating

Change of lighting time of filter sign

119

Cleaning of Return grille

INSTALLATION/SERVICING Tools

Maintenance

Clean the Return grilles with water

Part name ’ty Shape Usage

121

RAV-SM561, 801CT-E RAV-SM1101, 1401CT-E

Part name

122

123

Avoid installing in the following places

Installation space

124

Case of wireless type

Height of ceiling

Model name 561CT

How to use attached installation pattern

126

801CT

Pipe knockout hole

Installation of hanging bolts

Knockout hole of power cable take-in port

Draw-out direction of pipe/cable

Installation of indoor unit

Collective piping

Piping/Heat insulating material

Drain up

Adhesive inhibited

Case of taking pipe from the left side

Connection of drain hose Thermal insulating process

Connection of drain pipe

130

131

Refrigerant Piping and Evacuating

Flaring diam. meter size a Unit mm

Outer diam. of copper pipe

Refrigerant amount to be added

Piping with outdoor unit

Open the valve fully

Gas leak check

Remote controller wiring

Be sure to connect earth wire. Grounding work

133

Cable connection

134

Wiring diagram

135

136

137

138

Set data 0000

Case of installation to high ceiling

139

Set data

140

141

Removal of suction grille

Tools

Cleaning of air filter

Accessories

RBC-EXW21E

144

Timer set button

Operation procedure

Program button Cancel button

Holiday setting indication mark

146

147

148

RBC-AS21E

149

AS21E

150

Automatic Cool/Heat

RBC-AX22CE

151

Signal Receiving Part

Remote Controller

152

153

Operation Section Display Section

154

155

How to Match the Address

To Use the Remote Controller Setting to Wall, etc

How to Check the Address

When a signalis correctlyreceived, Pisoundcan be heard

Phenomenon Cause Measures

157

Start

Phenomenon Cause

158

Remote controller test run setup

Accessory parts

Requirement for installation Multiple remote controllers

How to perform cabling of the remote controller

Program Weekly Timer

160

How to install the remote sensor

Accessory parts

Requirement to install the remote sensor

161

Accessory

Installation of sensor unit

162

How to set the address switch

How to perform cabling of sensor units

How to set the room temperature sensor

Slide switch

164

How to set up filter sold separately of the high ceiling

How to handle the remote controller

Test run

To Personnel Charged in Installation Work and Service

’ty ØM5mm x 40mm ØM4mm x 12mm

Never modify or repair the product

Ceiling panel

Flap

Check after installation

Installation of adjust corner cap

Installation of suction grille

For wireless remote controller

TCB-DP22CE

168

To Disconnect the Appliance from Main Power Supply

Connect the connecting cable correctly

New Refrigerant Air Conditioner Installation

169

Knockout hole

Before installation

170

Connection of Elbow Piping KIT

Thermal insulating process

How to install drain up kit

171

Tightening connection

Connection of drain hose at drain up kit side

172

Connection of drain hose at indoor unit side

Piping/Heat insulating material

173

Check the draining

174

Use for Indoor Unit Only

For Installation Professionals

175

Combination List of Adapter Parts

Case of 4-way Ceiling Cassette RAV-SM **0 UT-E

176

Case of Concealed Duct RAV-SM **0 BT-E

Setup from the remote controller at the indoor unit side

Address No. setup table SW01

Procedure

Setup by the switch on the adapter P.C. board

178

To Customers

TCB-KP12CE TCB-KP22CE

179

Parts List

180

181

182

Installation of high-efficiency filter

Setup of fan when building in the high-efficiency filter

High-Efficiency Filter

183

Setup of fan when building in the filter sold separately

Deodorant Filter, Ammonium Filter

Page

Memo

![]() outdoor unit side

outdoor unit side