LinStep+ Dual-Axis Microstepping Indexer/Driver

Table of Contents

Arithmetic Operands and Equations

Other Programming Samples Ii Table of Contents MN1854

Increment/Decrement Variables

Troubleshooting Serial Communications Problems

Iv Table of Contents MN1854

Section General Information

Limited Warranty

CE Compliance

Product Notice Intended use

Could result in injury or death

Could result in damage to property

On next 2General Information MN1854

Do not touch any circuit board, power device or electrical

Connection before you first ensure that power has been

Do not apply AC power before you ensure that grounds are

Voltages that are conducted to its power input terminals.

Extend more than 0.2 5 into keypad assembly

Instead, we recommend using a four wire Wye

Power is removed from the drive

Driver should have specifications compatible to the drive

Overview

Section Product Overview

Motors

Product Overview MN1854

Section Receiving and Installation

Power Dissipation

Mechanical Installation

Receiving & Inspection

2Receiving & Installation MN1854

GND

Input Power Conditioning

System Grounding Ungrounded Distribution System

Power Connections Power connections are shown in Figure

Wire Size and Protection Devices

4Receiving & Installation MN1854

MN1854 Receiving & Installation

Connection Locations 115VAC, 2 Axis

6Receiving & Installation MN1854

Tools Required

9 & 25 Pin RS-232 Cable Connections for UL Installations

RS-232 PC Connections

8Receiving & Installation MN1854

Daisy Chain Connections

Rules for Daisy Chain Operation

PC / Host Device

Programmable I/O Connections

Optional Opto I/O Connections

These input connections are made at terminals 6-40 Figure

Typical connection each input

10Receiving & Installation MN1854

Encoder Signal PVS100 Danaher 9-Pin D

Encoder Color Code

+5VDC

Motor Connector

LD9068A00 Leadwire Connection 9 pin to flying leads

Interlock Intlk

Ground GND

Start-Up Procedure

Power Off Checks

Switch and Potentiometer Settings

Section General Information

Power On Checks

Action Display Comments

Motor should now be producing torque

High

Receiving & Installation MN1854

Section Keypad Operation

Overview

Keypad layout with the LCD display is shown in Figure

F1, F2, F3

Copies one program to another within the LinStep+

Comma

Decimal Point

Alpha

Test

Thus eliminating the need for a PC terminal connection

Trace Output Move

Shutdn RS232 Encoder

Edit Menu

Pressing the Edit key displays a set of sub-menus

Save the program

Edit an existing program

6Keypad Operation MN1854

Save Program? YesNo

Naming a program

Example of Naming a Program

Press ESC. You will be prompted as shown in Figure

Mine AC.3 VE2 DI1 GO

Use the =O keys for additional alpha characters

Entering Characters with the Alpha Key In edit mode

8Keypad Operation MN1854

Edit, Setup Submenu

Submenu Setup Parameter Description of Setup Parameter

Press EDIT, POS F3 Press YES F1 or no F3

Press EDIT, ↓ , List to

Display the number

Programs stored Press ↓ to display the total

Pressing Help in the Main Menu

Pressing Help in Menus and Sub-Menus

Pressing Help In the Program Edit function

Sequentially Eeprom message disappears

COPY, to PAD Submenu

Enter the program number. Or, if

You wish, you can scroll the list

Program names

Section Setup

Procedure Format Definition

Setup MN1854

Axis One Motor Type Steper

Axis One Drive Res

Axis One Motor Dir

Axis One ENC Mode

Open Loop

Application Notes

Axis One Encoder RES ↑5000 cnts/in ↓

IN-RANGE Setup Window

Value

IN-RANGE Window

PM Gain

Configure Your Application Mechanics

Mech Setup

Dist

Vmax Accel Amax

Axis One Vel Units In/s

Edit

Axis One MAX Vel

500.0 in/s ↓→

Iuuuuuuu ←↑↓→

Configure the I/O

Char Keypad Display Input Character Description

Inputs will work. See the RG command for more details

Service routine program

To summarize, when INT98CTRL=1

Reset to 1. This allows for input debounce and controlling

Warm Boot

Power-up program, if defined, will start

Jog Speed

Inputs

OUT1 Programmable Pppppppp ←↑↓→

Configure the Output States

OPTO9 Input

Iiiiiiii

OFF

Configure End of Travel Switch Polarity

Configure JOG Parameters

Enable

Accel LO-VEL HI-VEL

Mode Edge Switch

Configure Home Parameters

Offset DIR

Negative

Configure Power-up Program

↑SETUP↓

Power Up Program PROGRAM0

Axis One Final Dir Positive

Configure Serial Communications

RS232C Setup

↑ Enabled ↓

Echo UNIT#

Configure Miscellaneous Setup Parameters

Data Type Description of Display Data Type

General Password Rules

Password Setup

Opratr Admin Clear

Password Type Description Gives access to these menus

Keypad Program Command List

Section Keypad Programming

Acceleration Start Home Outputs On/Off

Function Key Message to Display

Keypad Programming MN1854

Value Units Range

Example

AC2 DE.5 VE12 DA3 GO DA3 GO DA3 GO

DC Distance to Change

Example Distance to Change

DCn * DCn*1 * Vn*1 2* Vnt w

Examples of DC move profiles, AC = seconds, VE=ips

DC n + 10 +

DE Deceleration

AC.1 VE60 DI2 GO DI1 GO DI-4 GO

LP2 DI3 GO EB

Value Units Range N/A

IF2,1 EN EB DI2 GO

=12 =13 =17 =18 =22 =23

=26 =27 =28

RUN Edit

Copy DEL

Example 3-Screen Menu Program

Set in Edit Setup Mech Accel VEL

GH Start Home

Go Immediate Syntax GI or GIi

Value N/A Units N/A Range N/A

GO Go Start a Move Syntax GO or GOi

Value N/A Units N/A Range i=1-16

AC.05 DE.05 VE50 DI5 GO

VE2 AC.1 DA4,2 GP

Gosub Syntax GSi and GSname

=1-400, name = any legal program name

IF10 Gtpart a EB

If input 1 is on and input 2 is off, jump to program Part a

Units Range

IFPARTS=25 GS20 EB

Lppieces

IV12,LENGTH

Dilength

Syntax LPi LP Loop

Value Units N/A Range N/A

Syntax MC+ MC Move Continuous

Move Continuous

MS27,COUNT

27 7th character, 2nd row

Powerup ONL,GTON EOT

Gthome

Main

VE5 DA20 GO

= starting output number

=0 input high. X=1 input low grounded

=anything else ignore input changes

OT4,1 Turn on Output OT2,0D1

Syntax RGr RG Registration

SQRESULT=0 SQ27.96,SQRESULT

Value N/A Units N/A

ST1 AC1 DE1 VE25 DA6 GO VE50 DA0 GO EN

Value N/A Units seconds

WTexpression

Syntax VEr VE Velocity

= starting input number

Helpful Hints Programming your application

Summary of Expressions, Operators and Functions

Programming Overview

Program

Example of Hosted Mode

Variable Names

Built-in Variables

Examples of how to use Built-in Variables

Variable Name Description of Built-in Variable Type

Using Built-in Variable Arowrel

Parts

Non-Volatile Variables

Lpnumber

AO15=VOLTAGE + Error

Arithmetic Operands and Equations

Examples of incorrect use

Instead, you should use

Logical Operators

Increment/Decrement Variables

Expressions

Other Programming Samples

Create a Message and Read an Input Variable

Setting an Output=On on-the-fly

Create a Menu menu display on keypad display for operator

Read a 4 Digit BCD number, 2 Digits at a time

Reading an Analog Input Value

GET 4 Bcds

Digit BCD=4 Digit BCD+2TW

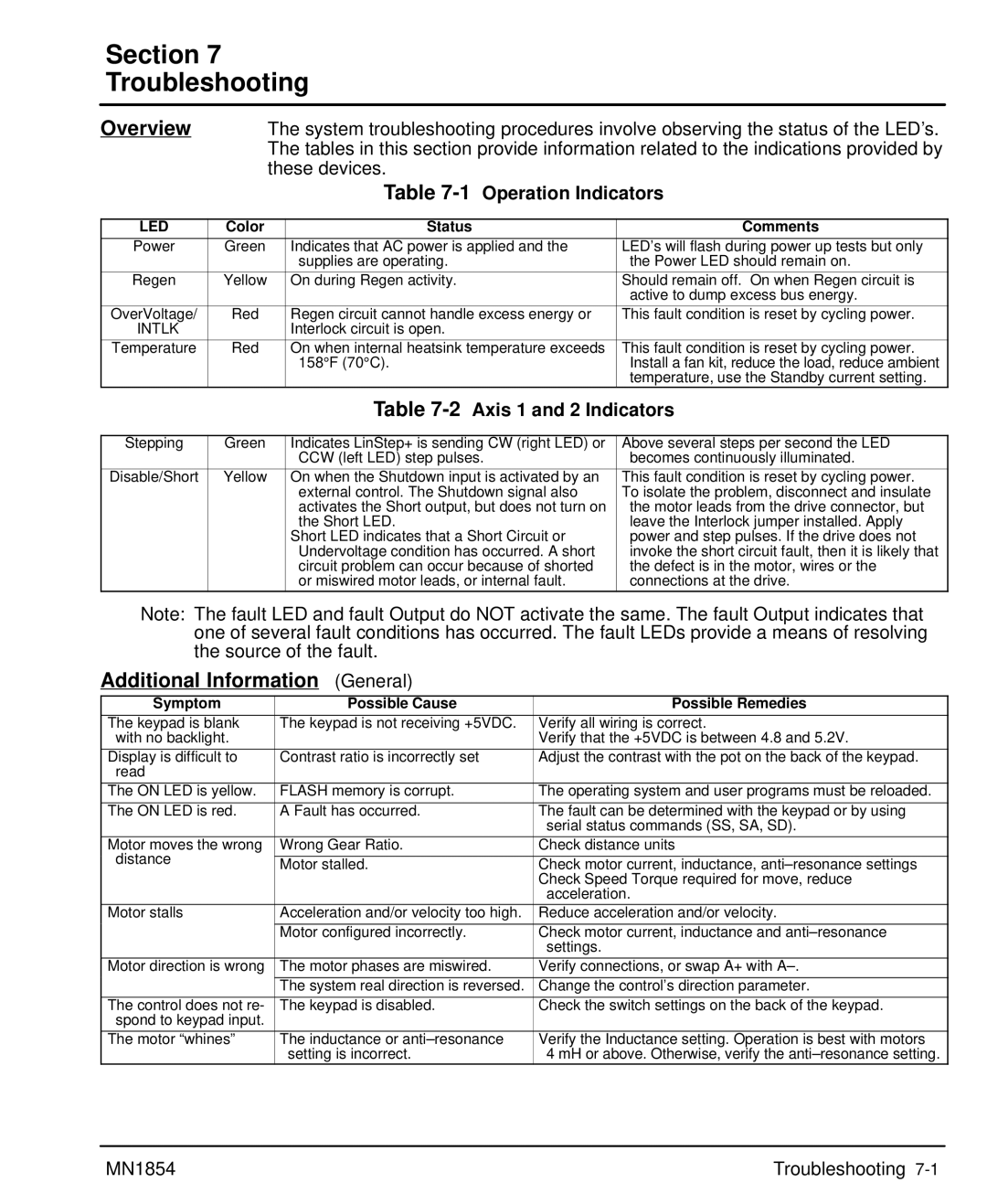

Section Troubleshooting

1Operation Indicators

2Axis 1 and 2 Indicators

Additional Information General

Troubleshooting MN1854

Additional Information

Serial Communications Problems

Troubleshooting MN1854

Section Specifications & Product Data

MN1854 Specifications & Product Data

Identification

LinStep+ LX 2 P 1 a

General Specifications

Protection & Indicators Description

VAC

VDC

Optional Keypad 10.08 256.0 Axis Driver 148.3

Dimensions

94.7 230.1

Specifications & Product Data MN1854

Wiring of Shielded Screened Cables

Section CE Guidelines

CE Declaration of Conformity

EMC Conformity and CE Marking

EMC Wiring Technique

CE Guidelines MN1854

Cit

Grounding Earth

EMC Installation Instructions

Cable Screens Grounding

Input Signal Cable Grounding

Simulated Encoder Output Cable Grounding

Encoder Cable Grounding

To Controller

Programming Template

Appendix a

MN1854 Appendix A-1

Appendix MN1854

MN1854 Appendix A-3

Remote Keypad Mounting Template

122.88

838

111.25

Baldor Electric Company

Baldor Electric Company MN1854 01 C&J

LinStep+ Dual-Axis Microstepping Indexer/Driver