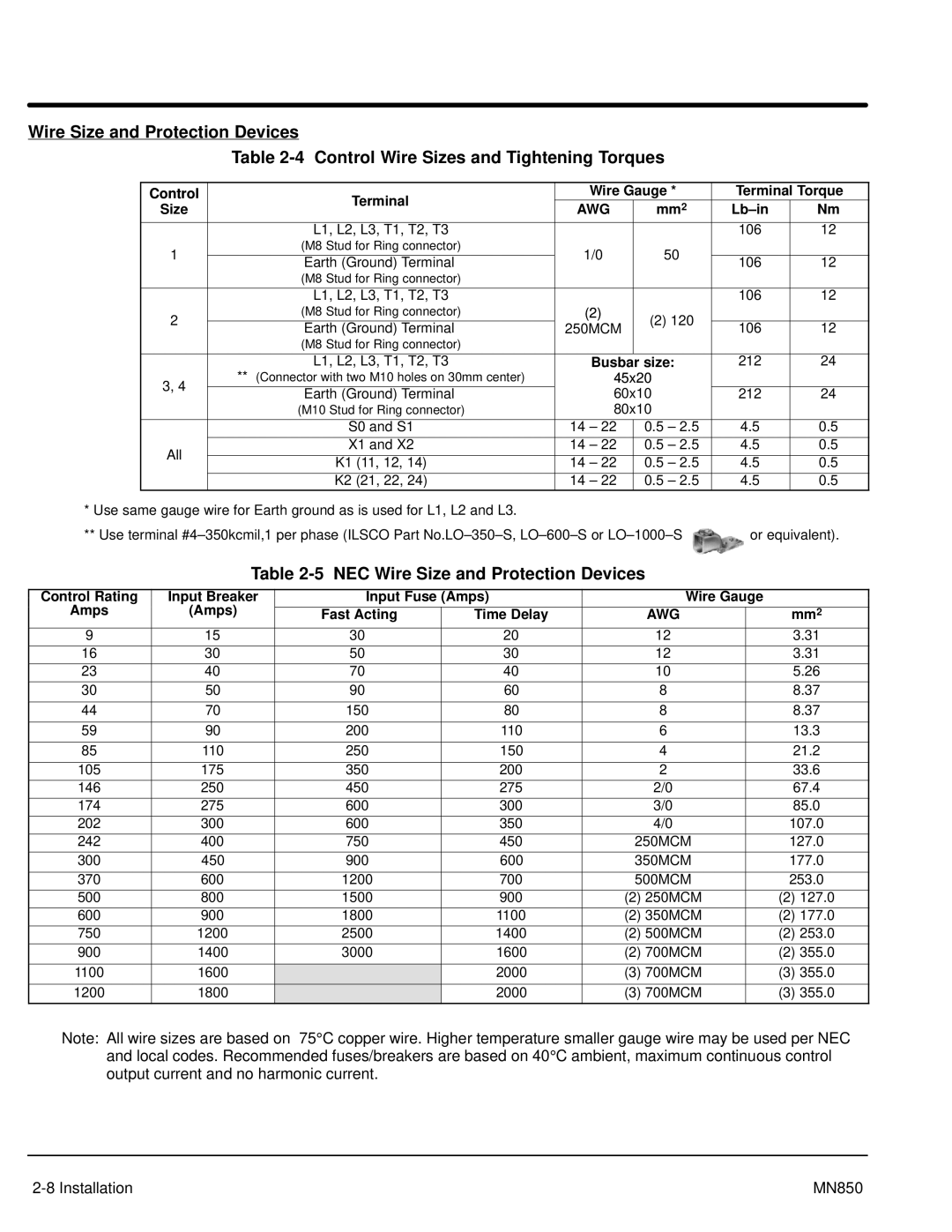

Wire Size and Protection Devices

Table

Control | Terminal | Wire Gauge * | Terminal Torque | |||

Size | AWG | mm2 |

| Nm | ||

| ||||||

| L1, L2, L3, T1, T2, T3 |

|

| 106 | 12 | |

1 | (M8 Stud for Ring connector) | 1/0 | 50 |

|

| |

|

|

| ||||

Earth (Ground) Terminal | 106 | 12 | ||||

|

|

| ||||

| (M8 Stud for Ring connector) |

|

|

|

| |

|

|

|

|

|

| |

| L1, L2, L3, T1, T2, T3 |

|

| 106 | 12 | |

2 | (M8 Stud for Ring connector) | (2) | (2) 120 |

|

| |

Earth (Ground) Terminal | 250MCM | 106 | 12 | |||

|

| |||||

| (M8 Stud for Ring connector) |

|

|

|

| |

|

|

|

|

|

| |

| L1, L2, L3, T1, T2, T3 | Busbar | size: | 212 | 24 | |

3, 4 | ** (Connector with two M10 holes on 30mm center) | 45x20 |

|

| ||

Earth (Ground) Terminal | 60x10 | 212 | 24 | |||

| ||||||

| (M10 Stud for Ring connector) | 80x10 |

|

| ||

|

|

|

|

|

| |

| S0 and S1 | 14 – 22 | 0.5 – 2.5 | 4.5 | 0.5 | |

All | X1 and X2 | 14 – 22 | 0.5 – 2.5 | 4.5 | 0.5 | |

K1 (11, 12, 14) | 14 – 22 | 0.5 – 2.5 | 4.5 | 0.5 | ||

| ||||||

| K2 (21, 22, 24) | 14 – 22 | 0.5 – 2.5 | 4.5 | 0.5 | |

*Use same gauge wire for Earth ground as is used for L1, L2 and L3.

**Use terminal ![]() or equivalent).

or equivalent).

Table 2-5 NEC Wire Size and Protection Devices

Control Rating | Input Breaker | Input Fuse (Amps) | Wire Gauge |

| ||

Amps | (Amps) |

|

|

|

|

|

Fast Acting | Time Delay | AWG |

| mm2 | ||

9 | 15 | 30 | 20 | 12 |

| 3.31 |

16 | 30 | 50 | 30 | 12 |

| 3.31 |

23 | 40 | 70 | 40 | 10 |

| 5.26 |

30 | 50 | 90 | 60 | 8 |

| 8.37 |

|

|

|

|

|

|

|

44 | 70 | 150 | 80 | 8 |

| 8.37 |

|

|

|

|

|

|

|

59 | 90 | 200 | 110 | 6 |

| 13.3 |

|

|

|

|

|

|

|

85 | 110 | 250 | 150 | 4 |

| 21.2 |

|

|

|

|

|

|

|

105 | 175 | 350 | 200 | 2 |

| 33.6 |

146 | 250 | 450 | 275 | 2/0 |

| 67.4 |

174 | 275 | 600 | 300 | 3/0 |

| 85.0 |

202 | 300 | 600 | 350 | 4/0 |

| 107.0 |

242 | 400 | 750 | 450 | 250MCM |

| 127.0 |

300 | 450 | 900 | 600 | 350MCM |

| 177.0 |

|

|

|

|

|

|

|

370 | 600 | 1200 | 700 | 500MCM |

| 253.0 |

500 | 800 | 1500 | 900 | (2) 250MCM |

| (2) 127.0 |

600 | 900 | 1800 | 1100 | (2) 350MCM |

| (2) 177.0 |

750 | 1200 | 2500 | 1400 | (2) 500MCM |

| (2) 253.0 |

900 | 1400 | 3000 | 1600 | (2) 700MCM |

| (2) 355.0 |

|

|

|

|

|

|

|

1100 | 1600 |

| 2000 | (3) 700MCM |

| (3) 355.0 |

1200 | 1800 |

| 2000 | (3) 700MCM |

| (3) 355.0 |

|

|

|

|

|

|

|

Note: All wire sizes are based on 75° C copper wire. Higher temperature smaller gauge wire may be used per NEC and local codes. Recommended fuses/breakers are based on 40° C ambient, maximum continuous control output current and no harmonic current.

MN850 |