Advanced Menu

Block Title | Parameter | Description | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advanced | Current | Rated Current – (View Only) this value is the continuous current rating of the control. | |||||||||||||||||||||||||

|

| Low Current – If on, activates low current trip protection. Useful to detect a low current | |||||||||||||||||||||||||

|

| condition (broken belt, coupling, pump etc.) on driven equipment. | |||||||||||||||||||||||||

|

| Low Current Level – The value of the low current trip detection. Value can be 0 to 100% | |||||||||||||||||||||||||

|

| of the Rated Current parameter value. Parameter 28. | |||||||||||||||||||||||||

|

| Low Current Time – The number of power cycles the motor current is allowed to remain | |||||||||||||||||||||||||

|

| below the low current level before a low current trip occurs. Value can be 5 to 255 | |||||||||||||||||||||||||

|

| cycles. Parameter 29. | |||||||||||||||||||||||||

|

| C/L Time Out – If on, allows current limit time out trip (active). | |||||||||||||||||||||||||

|

| Current Limit – The value of the current limit trip detection. Value can be 1 to 7.9 times | |||||||||||||||||||||||||

|

| the Rated Current parameter value. Parameter 30. | |||||||||||||||||||||||||

|

| Limit Time Out – The number of seconds | |||||||||||||||||||||||||

|

| Value can be 0 to 255 seconds. Parameter 31. | |||||||||||||||||||||||||

|

| Shearpin – If on, Shearpin protection is active. Useful to detect a high current condition | |||||||||||||||||||||||||

|

| (such as a jammed conveyor or press) on driven equipment. | |||||||||||||||||||||||||

|

| Shearpin Level – The value of the high current Shearpin trip detection. Value can be 1 to | |||||||||||||||||||||||||

|

| 5 times the Rated Current parameter value. Parameter 32. | |||||||||||||||||||||||||

|

| Shearpin Time – The number of power cycles the motor current is allowed to remain | |||||||||||||||||||||||||

|

| above the low shearpin level before a Shearpin trip occurs. Value can be | |||||||||||||||||||||||||

|

| cycles. Parameter 33. | |||||||||||||||||||||||||

|

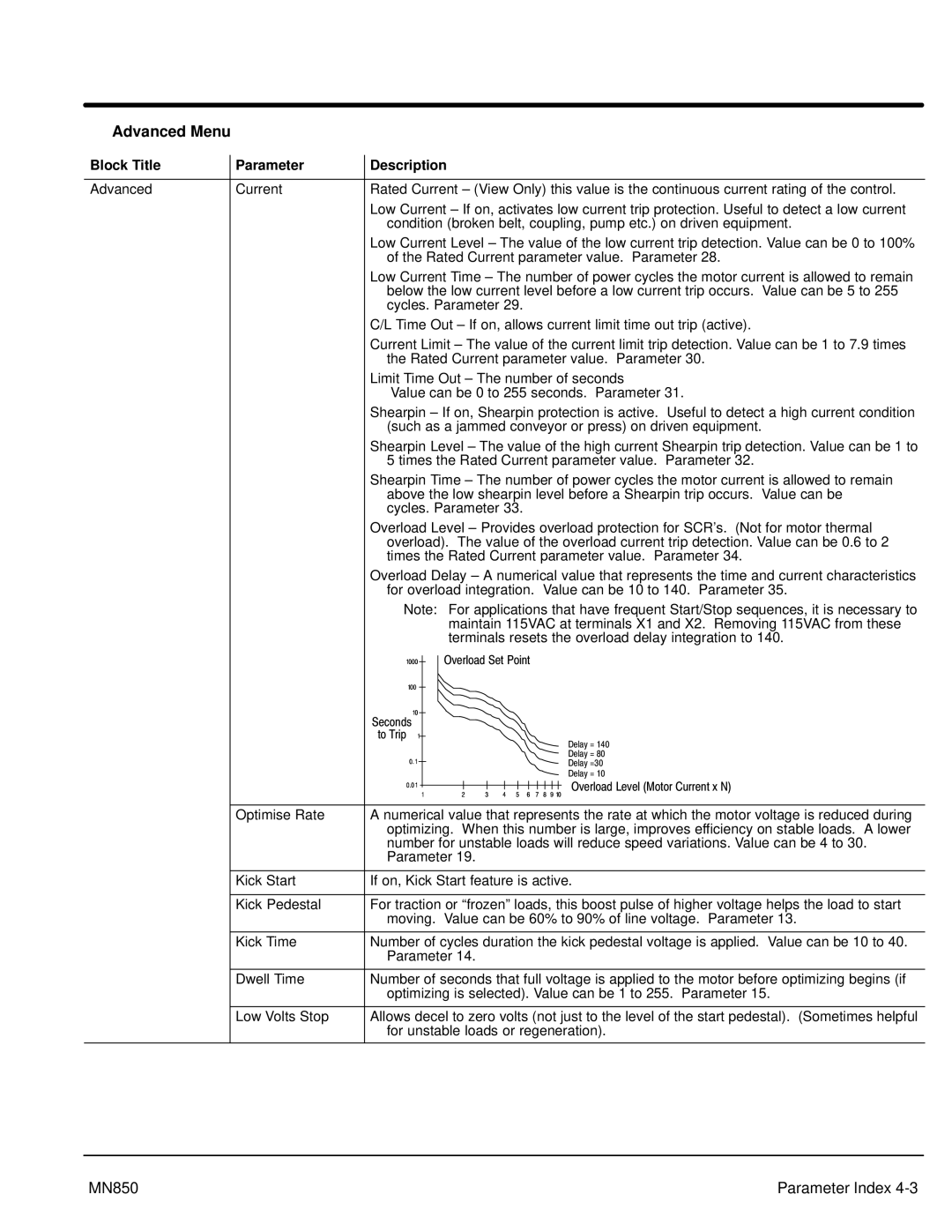

| Overload Level – Provides overload protection for SCR’s. (Not for motor thermal | |||||||||||||||||||||||||

|

| overload). The value of the overload current trip detection. Value can be 0.6 to 2 | |||||||||||||||||||||||||

|

| times the Rated Current parameter value. Parameter 34. | |||||||||||||||||||||||||

|

| Overload Delay – A numerical value that represents the time and current characteristics | |||||||||||||||||||||||||

|

| for overload integration. Value can be 10 to 140. Parameter 35. | |||||||||||||||||||||||||

|

| Note: For applications that have frequent Start/Stop sequences, it is necessary to | |||||||||||||||||||||||||

|

|

|

|

|

|

|

| maintain 115VAC at terminals X1 and X2. Removing 115VAC from these | |||||||||||||||||||

|

|

|

|

|

|

|

| terminals resets the overload delay integration to 140. | |||||||||||||||||||

|

|

|

|

|

|

|

| Overload Set Point | |||||||||||||||||||

|

|

|

|

|

| ||||||||||||||||||||||

|

|

|

|

|

| ||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Seconds |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| to Trip |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Delay = 140 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Delay = 80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Delay =30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Delay = 10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Overload Level (Motor Current x N) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| |||||||||||||||||||||||||

| Optimise Rate | A numerical value that represents the rate at which the motor voltage is reduced during | |||||||||||||||||||||||||

|

| optimizing. When this number is large, improves efficiency on stable loads. A lower | |||||||||||||||||||||||||

|

| number for unstable loads will reduce speed variations. Value can be 4 to 30. | |||||||||||||||||||||||||

|

| Parameter 19. | |||||||||||||||||||||||||

|

|

| |||||||||||||||||||||||||

| Kick Start | If on, Kick Start feature is active. | |||||||||||||||||||||||||

|

|

| |||||||||||||||||||||||||

| Kick Pedestal | For traction or “frozen” loads, this boost pulse of higher voltage helps the load to start | |||||||||||||||||||||||||

|

| moving. Value can be 60% to 90% of line voltage. Parameter 13. | |||||||||||||||||||||||||

|

|

| |||||||||||||||||||||||||

| Kick Time | Number of cycles duration the kick pedestal voltage is applied. Value can be 10 to 40. | |||||||||||||||||||||||||

|

| Parameter 14. | |||||||||||||||||||||||||

|

|

| |||||||||||||||||||||||||

| Dwell Time | Number of seconds that full voltage is applied to the motor before optimizing begins (if | |||||||||||||||||||||||||

|

| optimizing is selected). Value can be 1 to 255. Parameter 15. | |||||||||||||||||||||||||

|

|

| |||||||||||||||||||||||||

| Low Volts Stop | Allows decel to zero volts (not just to the level of the start pedestal). (Sometimes helpful | |||||||||||||||||||||||||

|

| for unstable loads or regeneration). | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MN850 | Parameter Index |