Installation, Start-Up Service Instructions

Make Unit Duct Connections

Instructions on

Roof Curb 48AJ,AK020-030 and 48EJ,EK024-034 Units

Roof Curb 48AJ,AK034-050 and 48EJ,EK038-048 Units

Roof Curb 48AJ,AK060 and 48EJ,EK054-068 Units

Page

Base Unit Dimensions 48AJ,AK020-030

Base Unit Dimensions 48AJ,AK035-050

Base Unit Dimensions 48AJ,AK060

Base Unit Dimensions 48AW,AY020-030

Base Unit Dimensions 48AW,AY035-050

Base Unit Dimensions 48W,AY060

Base Unit Dimensions 48EJ,EK024-034

Base Unit Dimensions 48EJ,EK038-048

Base Unit Dimensions 48EJ,EK054-068

Base Unit Dimensions 48EW,EY024-034

Base Unit Dimensions 48EW,EY038-048

Base Unit Dimensions 48EW,EY054-068

AT Each Corner %

Rigging Weights 48AJ,AK,AW,AY Units

AT Each Corner % 48EJ,EW,EK,EYD024

48EJ,EW,EK,EYD028

48EJ,EW,EK,EYD030

Physical Data 48AJ,AK,AW,AY Units

Unit 48AJ,AK,AW,AY

Quantity Rows...Fins/in

Physical Data 48EJ,EK,EW,EY Units

Unit 48EJ,EK,EW,EY

06D537 06EA250 06EA265

Quantity...Type Ckt 1, Ckt

Operating Weights

Evaporator Fan Motor Data

Air Distribution Thru-the-Bottom

Install Flue Hood

Combustion Fan Housing Location

Number of Stages Model Number Position Heat Size Htstgtyp

48A,E Series Staged Gas Implementation

Stages

Thermistor Designations

Supply-Air Thermistor Connections

Indoor Air Quality Sensor Configuration

Make Electrical Connections

CCN

COM

SIO

DIP

Unbalanced 3-Phase Supply Voltage

Electrical Data 48AJ,AK,AW,AY Units

Min Max

RLA LRA

Qty

30.8/28.0 180.5/177.7 225/225

236.3/230.9

Electrical Data 48EJ,EK,EW,EY Units

Range Exhaust FAN Motor

FLA LRA

MCA Mocp EW,EY

FLA LRA MCA Mocp EW,EY

54.0 23.6 41.6

NEC

FLA

RLA

Field Power Wiring Connections

GND Ground

CCB

Equip

GND

IFC

OFC

CCN IFC Pesc

Carrier Comfort Network Indoor-Fan Circuit

Indoor-Fan Relay Terminal Block

CCN Connection Approved Shielded Cables

Color Code Recommendations

Make Outdoor-Air Inlet Adjustments

Space Temperature Averaging Wiring

Adding Seal Strip to Top of Hood Sides

Adding Seal Strip to Sides of Hood Top Mounting Flange

Mounting Angle With Tabs Attached to Filter Track Assembly

Differential Enthalpy Control and Sensor

Psychrometric Chart for Enthalpy Control

Control Control Point Curve APPROX. DEG

Barometric Relief Damper and Power Exhaust Mounting Details

80.5 79.5 48EJ,EK,EW,EY024-054

Unit Size

120.5 119.5 48EJ,EK,EW,EY058-068

Motormaster III Sensor Location 48EJ,EK,EW,EY054-064

Field Modifications

Side Return Air Conversion

START-UP

Pressure Control Signal VFD SET Point

In. wg

Carrier Default Program Parameter Values

Parameter Group Default Value

Motor Standard Efficiency High Efficiency

Typical Factory Wiring Optional Field Wiring

Building Pressure Signal Level

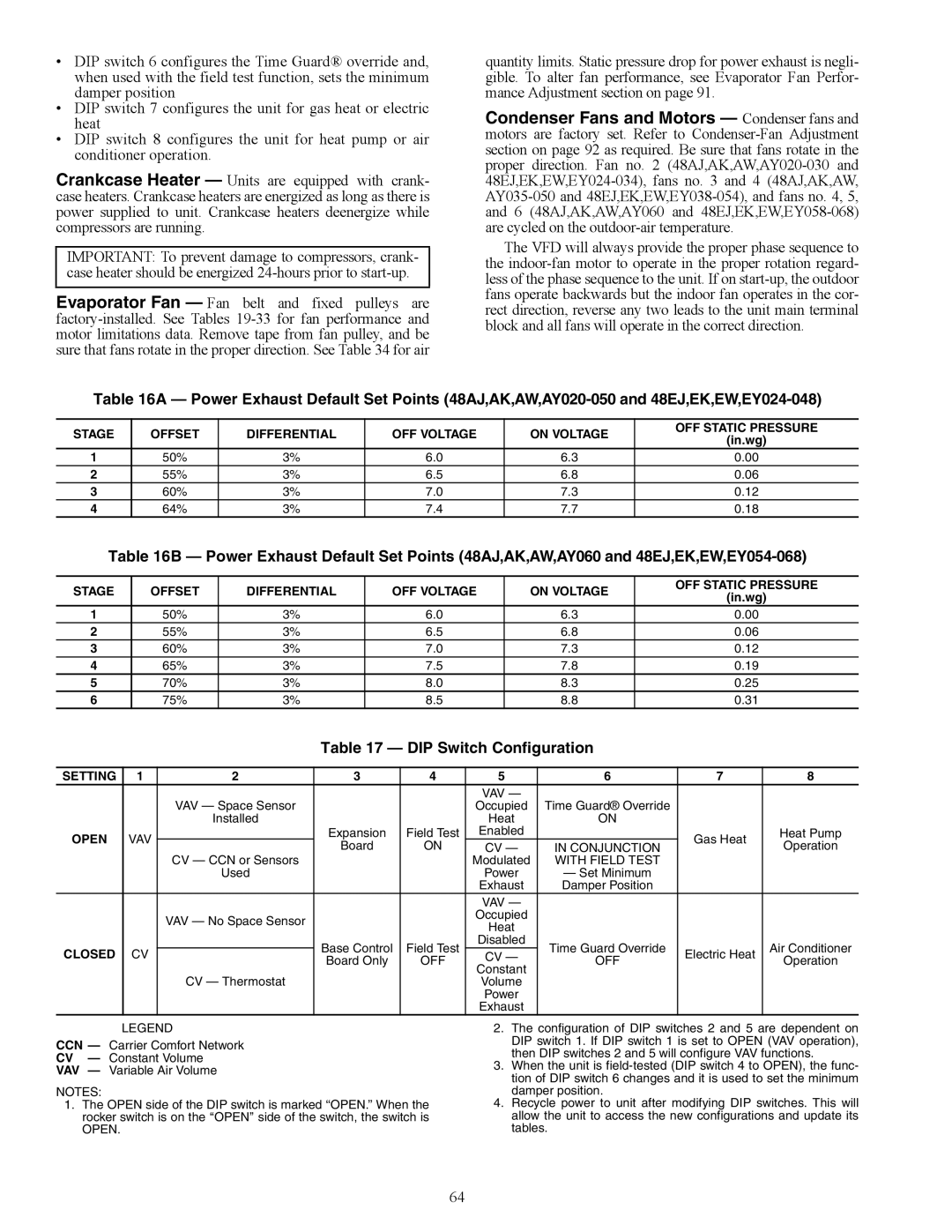

DIP Switch Configuration

Setting

Open

Closed

Fan Performance, 48AJ,AK020-030 Vertical Discharge Units

DIP Switch Factory Settings

Airflow

Fan Performance, 48AJ,AK035 Vertical Discharge Units

16,000

17,000

18,000

Fan Performance, 48AJ,AK040,050 Vertical Discharge Units

19,000

20,000

17,000 18,000 19,000 20,000

Fan Performance, 48AJ,AK060 Vertical Discharge Units

Fan Performance, 48AW,AY020-030 Horizontal Discharge Units

11,000 12,000 13,000 14,000 15,000

17,000 18,000

Fan Performance, 48AW,AY035 Horizontal Discharge Units

13,000 14,000 15,000 16,000 17,000 18,000

19,000 20,000

Fan Performance, 48AW,AY040,050 Horizontal Discharge Units

16,000 17,000 18,000 19,000 20,000

Fan Performance, 48AW,AY060 Horizontal Discharge Units

26,000 27,000

Fan Performance, 48EJ,EK024,034 Vertical Discharge Units

Fan Performance, 48EJ,EK038,044 Vertical Discharge Units

19,000 20,000 Available External Static Pressure in. wg

Rpm Bhp 000 1066 1096 1125

15,000 16,000 17,000 18,000 19,000 20,000

Rpm Bhp

Fan Performance, 48EJ,EK048 Vertical Discharge Units

000 1086 11.10 1114 11.61 1141 12.14

Fan Performance, 48EJ,EK054-068 Vertical Discharge Units

10,000 949 13.81 970 14.54 990 15.26

Fan Performance, 48EW,EY054-068 Horizontal Discharge Units

26,000 27,000 Available External Static Pressure in. wg

10,000 956 12.99 976 13.66 996 14.32

20,000 21,000 22,000 23,000 24,000 25,000 26,000 27,000

Airflow LOW Speed Medium Speed High Speed

ESP

Motor Limitations

Air Quality Limits

Sequence of Operation

User Defined Set Points

Software Control Link Points

Page

Heat Interlock Relay Wiring

COM Common

Staged Gas System Components

Stage Gas System Inputs/Outputs

Function Location

Input Description

Navigator Display

Navigator Display Menu Structure

Occupied Morning Temperature Software Heat

Version Enabled

DEG. F Reset

Condition

Field-Supplied Smoke Detector Wiring

Smoke Control Modes

Cooling Capacity Staging Table, CV Units with 2 Compressors

Device Pressurization Smoke Purge Evacuation Fire Shutdown

Stages

Service

Typical Gas Heating Section

Lubrication

Manufacturer Lubricant

Evaporator Fan Service and Replacement

Belt Tension Adjustment To adjust belt tension

Evaporator-Fan Motor Replacement

Condenser-Fan Adjustment

Gas Valve Adjustment

Cooling Charging Chart 48EJ,EK,EW,EY024-034

Cooling Charging Chart 48EJ,EK,EW,EY054-068

Protective Devices

Voltage Wire

Indoor Voltage Wire

06D-537 208/230-3-60 Following fan motors have two

20 HP 208/230-3-60

Typical 48EK VAV 24-V Control Circuit

Typical CV 24-V Control Circuit

Typical 48EK VAV 115-V Control Circuit

Typical 48EJ CV 115-V Control Circuit

101

102

Troubleshooting

Typical Refrigerant Circuiting 48AJ,AK,AW,AY027,030

Typical Refrigerant Circuiting 48AJ,AK,AW,AY035

Typical Refrigerant Circuiting 48EJ,EK,EW,EY038,044

Typical Refrigerant Circuiting 48AJ,AK,AW,AY040,050

Typical Refrigerant Circuiting 48EJ,EK,EW,EY048

Typical Refrigerant Circuiting 48EJ,EK,EW,EY054

Typical Refrigerant Circuiting 48AJ,AK,AW,AY060

Typical Refrigerant Circuiting 48EJ,EK,EW,EY064

Typical Refrigerant Circuiting 48EJ,EK,EW,EY068

IGC Control Heating and Cooling

IGC Control Board LED Alarms

Control Board LED Alarms

O Channel Designations Base Module CV

O Channel Designations Base Module VAV

Terminal no Assignment

IAQ

Service Training

START-UP Checklist

General