G R O U P

Page

RC Group 149ItEn.0102

MP2000 AIR Conditioners

Eprom CPX

Foreword

Generalita

MP2000 hardware configuration

Microprocessor Boards Board a and B

Schede a Microprocessore Board a E B

MP2000 AIR Conditioners

Terminal

Terminale

Scheda Addr

G V LEDs Dip-switch for address setting Connector

Scheda Indirizzamento

Addr Board

Switch OFF the system before mounting or removing the board

Boards Installation

Scheda ADDR+CK

ADDR+CK Board

Scheda T

Available on all connectors

Board

Tutti i connettori

Board Installation

Plug-in connector Connector

Porta Seriale RS485

Morsettiera estraibile 2. Connettore

Power

Humidifier Characteristics

Installation Diagram

Scheda Umidificatore

Remote Terminal

Terminale Remoto T

Possible Configurations of the MP2000 System

Possibili Configurazioni DEL SISTE- MA MP2000

Configurazione CON Board a E Terminale a Bordo Macchina

Configuration with Board a and Terminal on Unit

Board

Configuration with Board a and B and Terminal on Unit

MP2000 AIR Conditioners

Electric Connections

Connessioni Elettriche

Alimentazione Elettrica

Electric Feeding

Connessione TRA Board a E Board B

Dont use the connector for serial connection

Connection Between Board a and Board B

Connection Between Board a and T RE- Mote Terminal max 200m

GND

La connessione è a cura del Cliente

Connessione Seriale RS485

Serial Connection RS485

Connection is by Customer care

Serial connection with Modbus Jbus communica

Collegamento seriale con protocollo di comunicazio

Humidification System Connection

Connessione Sistema DI Umidificazione

LAN Connection

Connessione Rete LAN

Connection for manual temperature set point compen- sation

Connection of the Temperature SET Point Compensation System

⎟1V

⎟5V

Nota SU Come Manipolare LE Eprom E LE SCHE- DE Elettroniche

Installation of the Eprom

Inserimento Della Eprom

Keyboard Functions and PRO

Funzioni Della Tastiera E PRO

Grammazione

Gramming

Back to the Main Menu

Ritorno Alla Maschera Principale

Partenza Random Dellunita

Unit Switch on Main fan on

Funzione Chrono a richiesta

Funzione per lattivazione dellunità su fasce orarie

Next mask

600 to 1200 and from 1300 to

Limit Thermostat Function

AIR Delivery Temperature Indication

Inversione Senso Avviamento Compressori

Da Program set selezionare Limit thermostat enable Y

Premere Home per uscire dalla funzione

Compressors Starting Sequence Inversion

Hourmeter and Maintenance Alarm

Alarms Presence

Last 10 Alarms Visualization

Manual Procedure

Alarm Reset

AUT

OFF

AUT

OFF

Esempio

Example

Procedura manuale per valvole 0⎟10V e Floating

Manual procedure for 0⎟10V and Floating valves

Valve

By Arrow key select the Floating valves mask

SET Manufacturer

SET Point

Program Sets

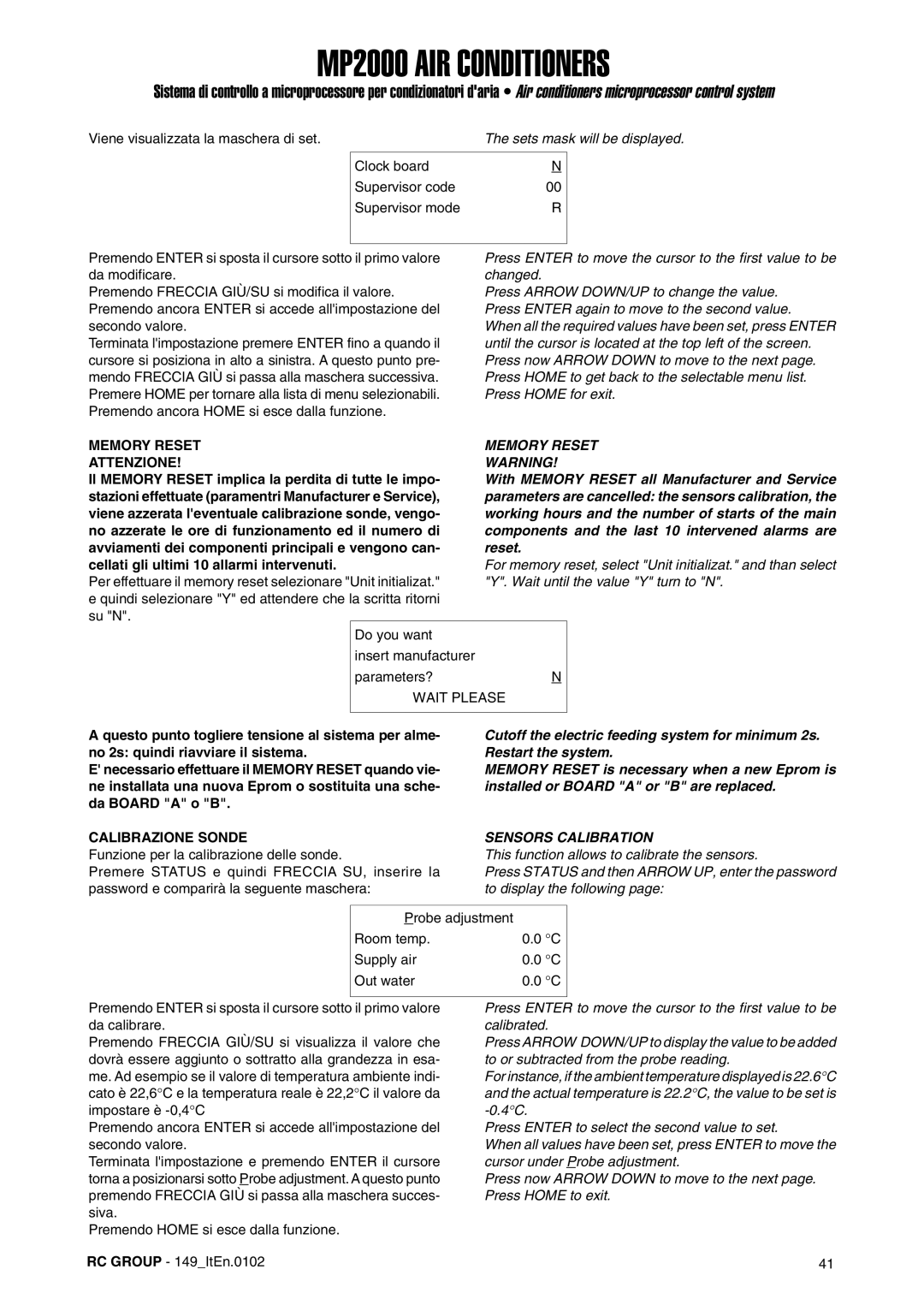

Sensors Calibration

Memory Reset

LAN Network Local Area Network

LAN Network Hardware CONFIGU- Ration

Configurazione Hardware Rete LAN

Address Code Setting

Impostazione DEI Codici DI Indirizzamento

Address Code

Codici DI Indirizzamento

Unita Terminale Board a Board B

Unit

LAN Network Software CONFIGU- Ration

Configurazione Software Rete LAN

Terminal Adr Board

Dove

Configurazione

Configurazione Software Manuale

Manual Software Configuration

Configuration

Configuration max

Configuration

Last mask is the following

Where

Masks List

Elenco Maschere

Definizione DEL Numero DI Unita Presenti NEL- LA Rete

Definition of the Number of Units Present in the Network

Terminal Sharing

Attenzione

Funzione Change Over

Parameters Setting

Impostazione DEI Parametri

Change Over Function

Alarm AL32 Unit not connected in LAN

How to reset the lock unit

Alarms

Rete LAN CON Funzione Combinata Chrono / Change Over

Rete LAN CON Funzione Chrono

LAN Network with Chrono Function

LAN Network with Combined Chrono /CHANGE Over Functions

Principles of the Control System

Symbols Used on Graphs

GLI Stadi ON/OFF

Temperature Proportional Signals

ON/OFF Stages

Segnali Proporzionali DI Temperatura

Segnali Proporzionali DI Pressione

Pressure Proportional Signals

LA Valvola a TRE Punti Floating

Floating Valve

22,3 XFs XFe

Limit Function for Dehumidification

LA Funzione Limit PER LA Deumidificazione

Disattivazione allarme set isteresi

Thermohygrometric Alarms

GLI Allarmi Termoigrometrici

Eprom Identification

Identificazione Eprom

MP2000 AIR Conditioners

Eprom CZX

Board a INLETS/OUTLETS Diagram

Schema INGRESSI/USCITE Board a

Available voltage free contacts

INGRESSI/USCITE Board a

Board a INLETS/OUTLETS

Board B INLETS/OUTLETS Diagram

Schema INGRESSI/USCITE Board B

Board B INLETS/OUTLETS

INGRESSI/USCITE Board B

SET List

Elenco SET

Unit Configuration

General Parameters Press for 4 seconds Than digit Password

Eprom CZX.... Software for air conditioners

Timing Parameters

Threshold Hour Meter

Status List

Elenco Status

Heating Valve

Cooling Valve

Control Cond

Main FAN

WAT. Level

Humidifier NOMIN. Amps

Conduct

Mode

List of Manual Sets

Elenco Sets Manuali

Elenco Memo

Memo List

Cooling Logic with Direct EXPAN- Sion Unit

Logica DI Raffreddamento CON Unità AD Espansione Diretta

XdzH1 High temperature limit stop dehumidifi Cation 1.2C

Unloaded mode or low speed of the com

XDH1 High Temperature Limit Differential

XH.Prealarm Offset room Temperature High prealarm 4.5C

Xdz2 Step compressor 2 Stage On 2.5C

Cation stage

XdzH1 High temperature limit stop dehumidifi Cation 2.2C

Mum cooling value

FC System Working Logic

Logica DI Funzionamento Sistema FC

Pegasus DXW

Cooling Logic with Chilled WA- TER Unit

Logica DI Raffreddamento CON Unità AD Acqua Refrigerata

XFe1 Cooling floating Valve Max 1,5C

Porzionalmente

=0 V 100%=10V

Mento e deumidificazione se presente

XD2 Step compressor 2 Differential 0,7C

XD7

Logica DI Riscaldamento CON RE- Sistenze Elettriche

Heating Logic with Electric HEAT- ERS

XL.Alarm Offset room Temperature Low alarm

XdzL1 Low temperature limit stop dehumidifi Cation 1.8C

XPs2 Heating proportional Valve Start 0.3C

XPe2 Heating proportional Valve Max 1.5C

Heating Logic with HOT Water SYS- TEM

Logica DI Riscaldamento CON SI- Stema AD Acqua Calda

XFs2 Heating floating Valve Start 0.3C

Decrease

Ture alarm

Temperature differential for dehumidifica

Tion stage

Hysteresis is fixed at 0.5C

Humidity Control Logic

Logica DI Controllo UMIDITA’

SET Reduce HUMID. in Cool Position

Condensing Pressure Control Logic

Logica DI Controllo Della PRES- Sione DI Condensazione

ZH.Alarm Maximum pressure value 2500kPA

ZH.Alarm Maximum pressure value 2500kPa

Logica DI Compensazione SET Point DI Temperatura

Temperature SET Point COMPEN- Sation Logic

Example for positive compensation cooling

Example for negative compensation heating

Eprom CPX

24Vac 24Vac

Contatti puliti disponibili

INGRESSI/USCITE Board a

Schema INGRESSI/USCITE Board B

Board B INLETS/OUTLETS

INGRESSI/USCITE Board B

Compressor 1 in cooling mode

Outlet condenser water

100

RC Group 149ItEn.0102 101

102

RC Group 149ItEn.0102 103

OUT. Water

LO Press

LO Press

Indicates the suction pressure value of cooling circuit

DIG.

HEAT. Valve

HEAT. Valve

Indicates the electric heater operating status

EXT. AIR Temp

Probe Calibration

LO Pressure

HI. Pressure

Cooling

For the following components and functions

Heatpump

Heater Compr

Logica DI Raffreddamento CON Unità a Espansione Diretta

XD2 Step compressor 2 in cooling mode Dif Ferential 0.7C

XD3 Step unloader 1 in cooling mode Differential 0,7C

XD3 Step unloader 1 in cooling mode Differ Ential 0.7C

XD4 Step unloader 2 in cooling mode Differ Ential 0.7C

XPs1 Cooling prop. Valve Start 0.3C

Af Setpoint fresh air 30%

XPe1 Cooling prop. Valve Max 1.5C

Af Setpoint fresh air 30%

RC Group 149ItEn.0102 111

FREE-COOLING ENABLING/DISABLING Logic Roof TOP units

Heating Logic

Logica DI Riscaldamento

XD6 Step compressor 2 in heating mode Dif Ferential 0.7C

XD7 Step unloader 1 in heating mode Differ Ential 0.7C

XD8 Step unloader 2 in heating mode Differ Ential 0.7C

Temperature

YD2 Step humidification differential 5%rH

Ydz2 Step humidification Stage On 10%rH

YPe1 Integrated humidifier Max capacity 10%rH

Ity production

RC Group 149ItEn.0102 115

Dità ambiente

ZP2min Condensing out min. value Condensing out Min value

ZP2s Control condensing Pressure set Set 1400kPa

ZP2max Condensing out max. value Condensing out Max value

Control condensing Pressure 2200kPa

RC Group 149ItEn.0102 117

OFF Control condensing Pressure OFF

OFF Control condensing Pressure OFF

118

Defrosting Conditions

Logica DI Sbrinamento PER Pompa DI Calore

Defrosting Logic for the Heat Pump Units

With DXW configuration With Condenser type = Water

Defrosting Procedure

Modalita DI Sbrinamento

Air defrosting

RC Group 149ItEn.0102 121

Alarms list and description

Logica DI Gestione Rele DI REMO- Tizzazione Allarmi

Relay Handling LOGIC, for the ALARMS’ Remote Control

Elenco Allarmi

Descrizioni Allarmi

Alarm Description

Heat Pump Program

AL 05 Compressor 1 High Pressure probe

AL07 Compressor 1 Low Pressure Air Conditioner Program

AL 09 Water on the Floor

AL08 Electric Heater Safety Thermostat

AL 10 Room Temperature High prealarm

AL 12 Room Temperature Low

AL 11 -Room Temperature High

AL 13 Room Humidity High

AL 14 Room Humidity low

AL 16 External Alarm

AL 15 External Alarm

AL 17 Compressor 2 Thermal Relay

AL 18 Compressor 2 High Pressure probe

AL21 Sonda Umidità Guasta

AL20 Bassa Pressione Compressore Programma condizionatori

AL20 Compressor 2 Low Pressure Air Conditioner Program

AL 21 Failure of the Humidity Probe

AL 23 Faulty Pressure Probe

AL 22 Failure of the Temperature Probes

AL22 Sonde Temperatura Guaste

AL23 Sonda Pressione Guasta

AL 26 Lack of current

AL 24 High Current

AL 25 Lack of water

AL 30 Compressor 2 Oil Differential

Al 28 Maintenance

AL 29 Compressor 1 Oil Differential

AL 35 Faulty Eeprom

AL 34 Clock card Faulty

AL 31 Smoke-Fire presence

AL 32 LAN network disconnected

Programma CPX Pompa di calore DXW con condenser type = Water

RC Group 149ItEn.0102 135

Components of the MP2000 system

Sonda DI Temperatura NTC

NTC Temperature Sensor

Technical Data

Temperature Element Technical Data

AIR Temperature and Humidity Sensor

Humidity Element Technical Data

Output signal

Refrigerant GAS Pressure Sensor

Sensore DI Pressione GAS Refrigerante

RC Group 149ItEn.0102 139

Amperometric Transformer for Humidifier Current TA 20/4

Max primary voltage 600 Vac Transformation ratio 08 V/V

Trasformatore Voltmetrico PER Tensione DI Linea TV

Voltmetric Transformer for Line Voltage TV

RC Group 149ItEn.0102 141

Trasformatore Amperometrico PER CORREN- TE DI Linea TA

Amperometric Transformer for Line CUR- Rent TA

100

Voltage Converter RC

Convertitore DI Tensione RC

RC275

AC/DC Converter

Sensore Acqua RC350

Relè Segnalazione Presenza Acqua RC420

Water Detection Relay RC420

Feeding

Relè Segnalazione Presenza Acqua LV2D

Feeding 24/48Vac 50/60Hz 2VA Switching power

Water Detection Relay LV2D

Sensitivity ⎟ 12 kΩ Insulation KV RMS

Installation Note

FAN Motor Speed Controller for Single Phase Motors P11

Regolatore DI Velocità PER Motori MONOFA- SE P11

Functions

Regolatore DI Velocità PER Motori Monofa

Phase Motors P12

FAN Motor Speed Controller for Single

Connection

Regolatore DI Velocità PER Motori MONOFA- SE RIV

FAN Motor Speed Controller for Single Phase Motors RIV

105

170

Max current Protection degree IP65 Input fuse 3A type L

Collegamenti Elettrici

Electric Connections

Regolatore DI Velocità PER Motori TRIFA- SE DVR

FAN Motor Speed Controller for Three Phase Motors DVR

280

140

Potentiometer 10kΩ

Set tarato in fabbrica a 9,5Vdc non modificare 152

FAN Motor Speed Controller for Three Phase Motors FCS

Regolatore DI Velocità PER Motori TRIFA- SE FCS

JP9

LIN/QUAD

LIN/QUAD JP9

Input JP5 Not used

Convertitore DI Segnale AD 1 Stadio RC411A

Stage Signal Converter RC 411A

Within the device is located an A/C jumper

24Vac ±15% 50/60Hz 1VA

Feeding Switching power Insulation Signal input Delay

Stages Signal Converter RC470

Convertitore DI Segnale a 3 Stadi RC470

RC Group 149ItEn.0102 155

Massima Corrente 1,5 a

Rele DI Protezione Minima Corrente RC460

Minimum Current Protection Relay RC460

Maximum Current 1,5 a

Il valore di intervento è tarabile da 0,5 a 5A

Terminals

Flexi Control RC480a

Device for Flexibox Terminal Units

RC Group 149ItEn.0102 159

Flexi Control RC480b

Room Regulator for Flexibox RCE84.21

Regolatore Ambiente PER Flexibox RCE84.21

Xpk

Fixed temperature set point 21C

Setpoint preimpostato temperatura 21C

Xpk

BOX Diodi PER Segnali 0⎟10V RC285

Diodes BOX for 0⎟10V Signals RC285

7 P

Collegare esclusivamente segnali analogici di tipo

Pressostato Differenziale Aria

AIR Differential Pressure Switch

24Vac

Max differential pressure Mbar

Proportional Actuator for Damper DMS

Servomotore Proporzionale PER Serrande DMS

Servomotore Proporzionale PER Serrande GDB161.1E

Control signal ⎟ 10 Power

Proportional Actuator for Damper GDB161.1E

2VA

Proportional Actuator for Damper NM24-SR

Servomotore Proporzionale PER Serrande NM24-SR

3VA

24Vac ±20% 50/60Hz

Counter-clockwise rotation

ON/OFF Actuator for Damper DAS

Clockwise rotation

Power 3VA Force 420N Stroke 5mm Running time 160⎟170sec

Way valves running mode

Floating Actuator for 2/3 WAY Valves SQS

Funzionamento valvole a 2 vie

Servomotore CON Comando 0⎟10V PER Valvo

Running mode

⎟10V Actuator for 2/3 WAY Valves

SQS

SQX

LE a 2/3 VIE SQX

Regolatore DI Velocità PER Motori MONOFA- SE FV31

FAN Motor Speed Controller for Single Phase Motor FV31

R22 R407c refriger- ant

R134a refrigerant

FSF 41S

Regolatore DI Velocità PER Motori MONOFA- SE FSF41S FSF42S

FSF 42S

16,2

Pressostati DI Tipo ON/OFF PER Alta E Bassa Pressione PS3

ON/OFF Type High and LOW Pressure Switches PS3

230Vac ±15%

Supply voltage

Tabella Identificativa Pressostati PS3

PS3 Pressure Switch Identification Table

175

Protection IP65 Switching power

Descrizione Parametri

Programmazione Parametri

Parameters Programming

Description of Parameters

Error Signalling

Segnalazione Errore

Elemento Sensibile

Sensible Element

OCO Output connection Set point dependency

D2 Differential. Same as d1

= Heating C = Cooling

HC1 Heating/Cooling output 1 Relay switch function output

HC1 Heating/Cooling uscita 1 Modo di funziona- mento uscita

180

Page

RC Group