GE Fanuc Automation

GFL±002

Preface

Preface

Related Publications

Contents

Chapter Configuration

Appendix a TÜV Certification Appendix B Maintenance Override

Chapter Introduction

Components of a GMR System

Series 90-70 PLCs

Inter-processor Communications

Busses and Bus Controllers

Additional Bus Controllers for Communications

Operation Overview

Input Subsystem

PLC Subsystem Voting on Input Data

Automatic System Test

PLC Subsystem Providing Output Data

Output Subsystem

Genius I/O Blocks

Discrete Blocks

Analog, RTD, and Thermocouple Blocks

Block Summary

Number of I/O Points in a GMR System

Number of Non-GMR I/O Available for the 788 CPU

Number of Non-GMR I/O Available for the 789 CPU

798

Configuration and Programming

GMR

Basic Steps of Configuration and Programming

Chapter Input Subsystem

Overview

GMR Input Groups

One sensor to one Genius input

Inputs from non-GMR I/O blocks

Non-Voted I/O in the Input Subsystem

Inputs from single-block simplex GMR input groups

Discrete Inputs

Types of Blocks in the Input Subsystem

Discrete Input Processing

Discrepancy Reporting for GMR Inputs

Input Autotest for GMR Inputs

Calculating Voltage Drops on Tristate Inputs

Line Monitoring for Discrete Inputs

Normally-closed Inputs

Normally-open Inputs

Input Filter Time

Manual Input Controls

Analog Inputs

Voted Analog Inputs

Number of Input Sensors per Voted Channel

Analog Voting Adaptation

Non-GMR Analog Blocks

Analog Discrepancy Reporting

Non-Voted Analog Inputs in GMR Input Groups

Chapter Output Subsystem

Types of Blocks in the Output Subsystem

Output Voting

Duplex Default for Outputs

GMR Output Handling

Results of Block Group Voting with Three PLCs Online

Output Fault Reporting

PLC Logon Control

Block Output Groups

Output Load Sharing

Bus Redundancy in a 4-Block Output Group

Electrical Characteristics of Sink and Source Blocks

Operation of a 4-Block Output Group

Manual Output Controls and Diagnostics

GMR Mode

Redundancy Modes for Output Blocks

Hot Standby Mode in a GMR System

Hot Standby Mode

Basic Hot Standby Mode Operation

Chapter PLC Subsystem

System Startup

All GMR bus controllers at serial bus address

Online Changes

Data Initialization

CPU Sweep in a GMR System

PLC Operation

Important Note

Estimating CPU Sweep Time

Sweep Time Contribution of Genius I/O and GBCs

Discrete Inputs

Input Processing

Discrepancies

Discrete Input Voting

Voting with Three Discrete Inputs

Voting with Two Discrete Inputs

Voting for One Discrete Input

Analog Inputs

Analog Input Voting

Voting for Three Analog Inputs

Voting for Two Analog Inputs

Voting for One Analog Input

Output Processing

Discrete Outputs

Shutdown

Synchronous or Asynchronous Input Autotest and I/O Shutdown

Output Faults that Cause I/O Shutdown

M12244 ± Iosd Any I/O Shutdown Timer Activated

M12265 ± Sdcan Cancel I/O Shutdown

Programming for I/O Shutdown

Hours

Shut Down Recovery

Shut Down Prevention

Global Data Redundancy

Entering, Clearing, or Setting Global Data

Communications Between PLCs

Chapter Diagnostics

Programming for Diagnostics

Output Diagnostics

Diagnostics in a GMR System

Input Diagnostics

Setting Up Blocks to Report Genius Faults

Setting Up Other Blocks to Send Multiple Fault Reports

CPU Redundancy Mode Configuration Block Type

Summary Table

GMR Autotesting

Autotest Sequence

Discrete Input Autotest

Configuration Required for Discrete Input Autotest

Setup for Input Autotest

Operation of the Input Autotest

Circuit Fail Mask

Discrete Output Autotest

Operation of the Discrete Output Autotest

Block a Pulse-tested

Pulse Test Operation

GMR Discrepancy Reporting

Discrete Input Discrepancy Reporting

Input Data

Voted Discrepancy Inputs

Discrete Output Discrepancy Reporting with Dynamic Outputs

Discrete Output Discrepancy Reporting

How Output Discrepancy Checking is Performed

Analog Input Discrepancy Reporting

Input Line Fault Detection in a GMR Application

PLC and I/O Fault Tables in a GMR System

Clearing the Fault Tables in a GMR System

Fault Table Messages for GMR

Reporting of No-Load Faults on 4-Block Output Groups

Fault Type for Output Autotest

Fault Description Code Hex Meaning

Fault Specific Data

Message

PLC Fault Table Messages for GMR

Code

Code

Code

10903

Code

Manual Output Controls and Diagnostics

Monitoring Manual Output Controls

Fault, No Fault, and Alarm Contacts

Discrete Input Fault Contacts for GMR

Discrete Output Fault Contacts for GMR

Contact References Associated with an Output

ShortCircuitfault Overtemperaturefault Overloadfault

Analog Fault and Alarm Contacts for GMR

Alarm Contacts

Fault Contacts for Analog Inputs

Fault Contacts for Analog Outputs

Chapter Configuration

Configuration Overview

Basic Steps of Configuration

For Information to be copied set only Configuration to yes

Using the GMR Configuration Software

GMR Configuration Software Revision and Checksum

Installing the Configuration Software

Getting Started

Mouse and Keyboard Guide for the Configuration Software

Using a Mouse

Configuration

GMR Configuration Summary

Insert the first GBC bus controller group

Opening a Previously-Saved Configuration File

Creating/Selecting a File

Saving a Configuration File

Closing a Configuration File without Saving It

Changing to Another Directory

Entering a System Description

Starting a New Configuration

Closing and Deleting the System Configuration File

GMR Configuration Selections

When you select System, the following menu appears

Shutdown

CPU Configuration

Simplex

Test Interval

Period

Input Discrepancy Filter

Limits

Global Data

Initialization Data

+ %R data needed for the application Spare

Initialize Data

GBC1 GBC2

Parame Comment Ters

M12234

Fault Actions

M12232

Write Access

Adding Bus Controllers and I/O Modules

Genius Bus Controller Group Configuration

Exiting the Window

Exiting a Block Group Window

Configuring the Input Subsystem for a Bus Controller Group

Select To Configure

Start %I

SBA

Auto Test

GFK-0787B

Duplex State

GFK-0787B

Analog I/O Group Configuration

Vote Adapt Mode

Vote Adaptation

Default State

Analog Discrepancy Thresholds and Limits

Configuring the Output Subsystem for a Bus Controller Group

Start %Q

GFK-0787B

Options

Start Ref

Bus C inputs Reserved inputs

Configuration

References are 0001 to

CONFIG4

Creating the GMR10 Output File

Printing the GMR Configuration

Completing the Logicmaster 90 Configuration

Configuring Bus Controllers

Creating and Copying the PLC Configuration

Logicmaster Configuration Summary

GFK-0787B

Configuring GMR Bus Controllers and I/O Blocks

Configuring Genius I/O Blocks

Copying Configurations

Setting Up Blocks for Fault Reporting

Editing the Reference Addresses

Configuring 16-Circuit and 32-Circuit Discrete DC Blocks

Feature Circuit or Factory Selections Block Setting

Device

Serial bus

Circuit I/O Type Report Faults

Block I/O Type Baud Rate Pulse Test Input Filter Time

Configuration

Duplex Default

Duplex Output Default State Setting Block

Duplex Voted Output Default State Setting Block

Results of Block Voting with Only Two PLCs Online

Chapter

Programming Overview

Program Instruction Set for GMR

Estimating Memory Usage

Estimating Bus Scan Time

Use of Do I/O and Suspend I/O

References Reserved For

Memor y Write Access

Reserved References

Input and Output Addressing for GMR

Discrete I/O Addressing

1024 ± 16 ± 3 x 32 +1 = 913 = %I0913

Q1009 to %Q1024

I1009 to %I1024

Analog I/O Addressing

16 x 6 = 96 words required

AnalogOutput Addressing

Example

Register %R Memory Assignment for GMR

Memory Required for Startup Initialization Data

Monitoring Forces and Overrides

Monitoring the Fault Tables

System Status %S References

GMR Status and Control %M References

Status References

Resetting Status Flags

PLC OK Flags

Reference Nickname Description Meaning

Control References

M12257 Continue

M12262 Report

Clearing the PLC Fault Tables

40-characterConfiguration File Description

Programming for Startup

Monitoring Startup Status

Enabling Outputs At Startup

Powerup Note

Performing I/O Fault Reset

Fault. If both are not 1, initialization continues

Example Ladder Logic

These Program Blocks represent logic

Routines that are appropriate for Application

When a third PLC comes on line

Triplex bit is optional the need for this bit depends on

Programming for I/O Shutdown

Point Faults

Enabling I/O Point Faults

Programming for Fault and Alarm Contacts

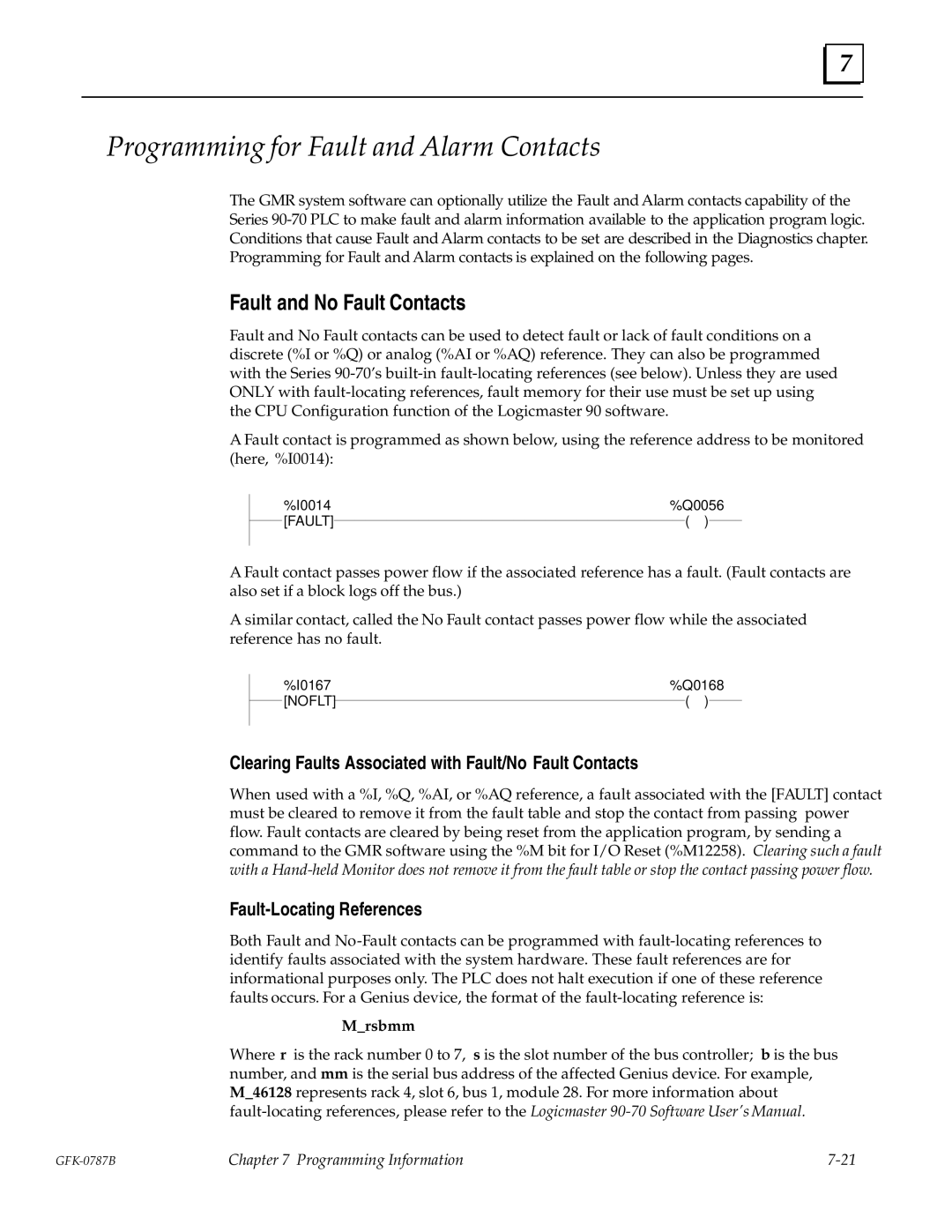

Fault and No Fault Contacts

Clearing Faults Associated with Fault/No Fault Contacts

Fault-Locating References

Discrete Input Fault Contacts for GMR

Discrete Output Fault Contacts for GMR

Analog Fault Contacts for GMR

Analog Alarm Contacts for GMR

Y3 dummy not used

Reading GMR Diagnostics

Parameters for the Call Function

Data Table Numbers

Contains

Range for Start Value

Range for End Value

Error Codes for GMR Diagnostics

Code Meaning

Programming for Global Data

Global Data for the Application Program

GFK-0787B

Adding GMR10 to the Logicmaster Librarian

Select F6 Add Element to Library

Do not Rename GMR10

Storing a Program to the PLC

GFK-0787B

Using the Store Function

Field Description

Storing an Identical Program Following CPU Replacement

Storing a Revised Program

Press the Space Bar to Continue

Using the Program Download Utility

Using the Download Utility with the Default PLC IDs

Customizing the Download Utility for Other PLC IDs

Processing Complete

Programming Information

GFK-0787B

Chapter Installation Information

Genius Bus Connections

Termination Boards

Input Wiring

Single Sensor to Three Blocks Triple Bus

Three Sensors to Three Blocks Triple Bus

Block Wiring for 16-Circuit Source Block in an Input Group

DC Source Block IC660BBD020

Block Wiring for 16-Circuit Sink Block in an Input Group

DC Sink Block IC660BBD021

Block Wiring for 32-Circuit Source Block in an Input Group

DC Source Block IC660BBD024

Block Wiring for 32-Circuit Sink Block in an Input Group

DC Sink Block IC660BBD025

Output Wiring for a 16-Circuit, 4-Block Group

Circuit, 4-Block Output Group

Block Wiring for a 16-Circuit 4-Block Output Group

Block a

ON±OFF±ON Test

Output Autotest and Pulse Testing

OFF±ON±OFF Test

GE Catalog Number CR7RBXXEL Spectra 700 IEC Control Relay

Output Wiring for a 32-Circuit, 4-Block Group

Block Wiring for a 32-Circuit 4-Block Output Group

Block a

GFK-0787B

Milliamp

Appendix

TÜV Restrictions

Catalog Number Firmware Description Revision Level

Appendix a TÜV Certification

COMMREQ, DATAINITCOMM, Call SUB, Callexternal

Appendix Maintenance Override

Project engineer Projectengineer, Typeapproval

Recommendations

Index

Index-2

Index-3

Index-4